Tailor-made, efficient, and reliable

Meeting the highest demands and defining industry standards, our BHS turbo gear portfolio includes innovative products with higher speeds, more power, and safety. Learn about our services, such as short delivery times and optimized costs, and contact us for your free consultation.

Features and benefits at a glance

Our turbo gear product portfolio

Our parallel gear units supply reliable and efficient power transmission within a power range of up to 85 MW and a speed range of up to 60,000 rpm.

Learn more

The integral gear unit is the central component and the heartbeat of your turbo gear compressor. Tailor-made to your requirements, these units are manufactured with up to ten compressor stages and weigh up to 70 tons.

Learn more

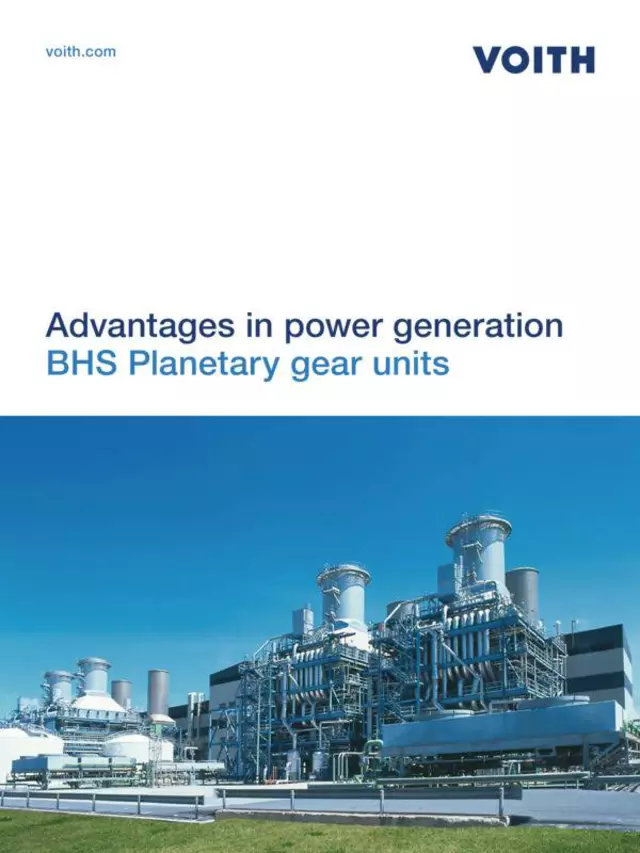

Ensuring high power density with a minimal space requirement at a lower-than-expected weight, our planetary gear units are proven in the field and designed based on the Stoeckicht principle.

Learn more

Power distribution gear units combine the advantages of the parallel shaft and planetary gear units in a turbo drivetrain. These gear units have a power range of up to 170,000 kW and reach speeds of up to 100,000 rpm.

Learn more

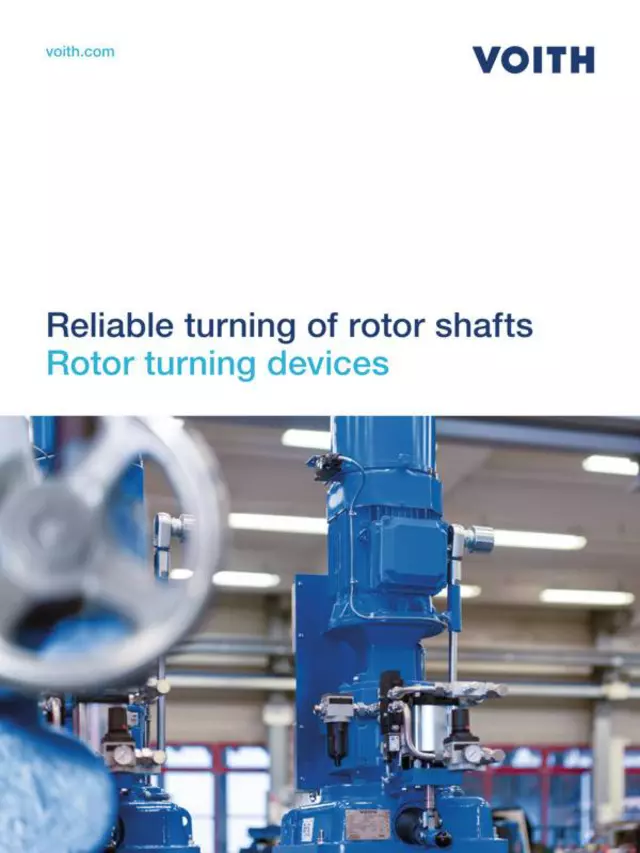

Wear-resistant and low-maintenance, our rotor turning gears for shaft trains are safe and reliable even at high turning speeds and breakaway torques.

Learn more

Reliable even within threshold ranges, our low-weight diaphragm couplings optimally transmit high torque at high speeds.

Learn moreProduct registration

In order to receive quick technical support in the event of service, we recommend registering your Voith product. You can scan the QR code on the product or click on the button below to register your turbo gear unit or component. Please provide us your contact details, the product name, the KVO number and optional the date of commissioning.

Register your product nowVoith Service - how can we help you?

- Everything from a single source: development, design, production – and service!

- Decades of product experience as an original equipment manufacturer and service provider

- Fast and smooth cooperation and best service thanks to a worldwide network of service locations

- Long-term partnership and planning security are guaranteed due to longstanding corporate stability

Publications

Show all publications

-

-

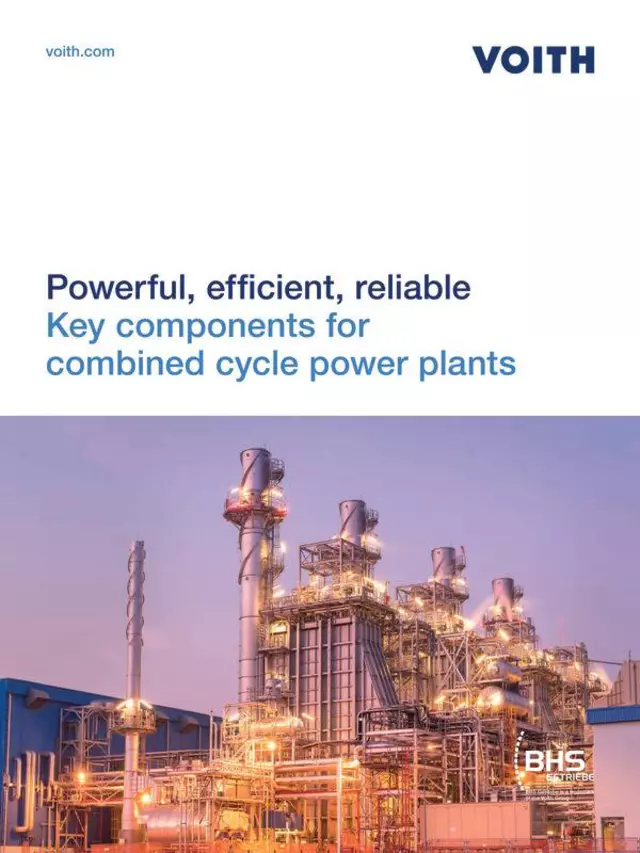

Powerful, efficient, reliable | Key components for combined cycle power plants

PDFEnglish Portuguese Russian -

-

-