All from one single source

Our global team fights for the success of papermakers, delivering robust solutions to meet our customers’ needs – all from a single, reliable source. Based on our expertise and experience, we optimize along the entire machine life cycle. Digitally enabled combinations of our unique product and services portfolio set the benchmark in the industry. Innovations and breakthrough technologies ensure maximum efficiency and sustainability of our customers’ papermaking process.

Product and service finder

Finding a specific product or service has never been easier! All you need to do is to enter a keyword or product name or simply use the filters to get more information about the needed product or service.

Discover our broad portfolio of products and services

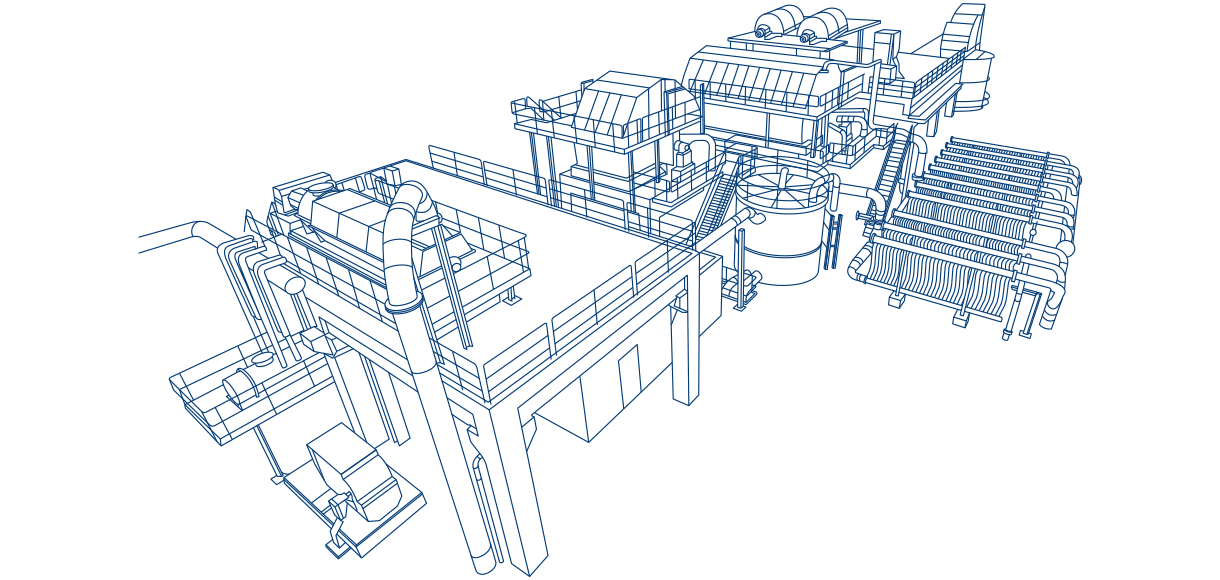

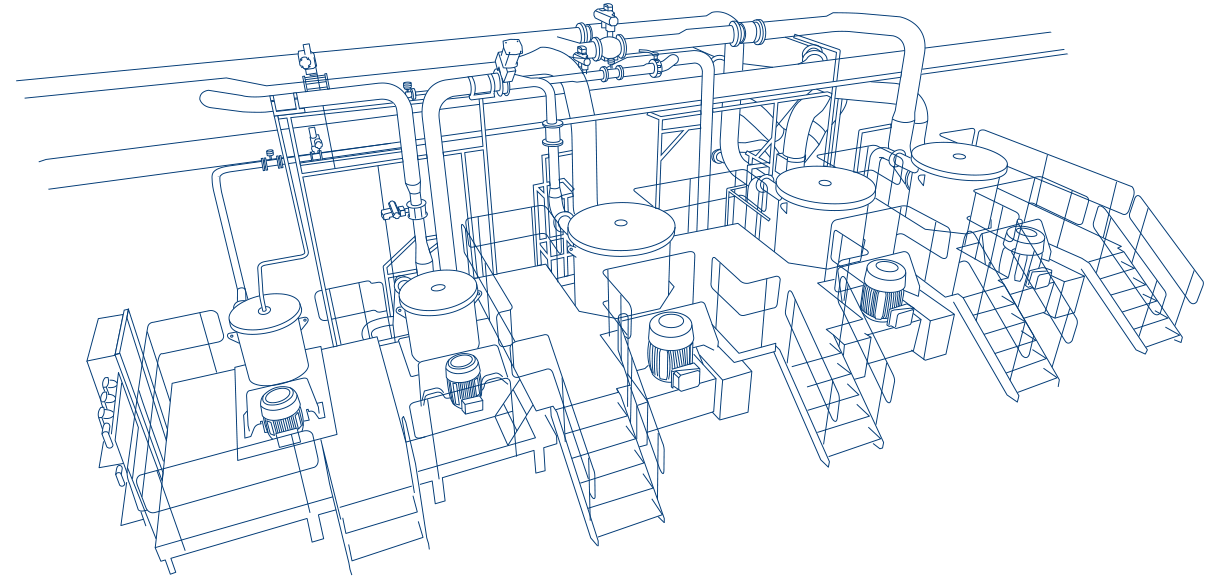

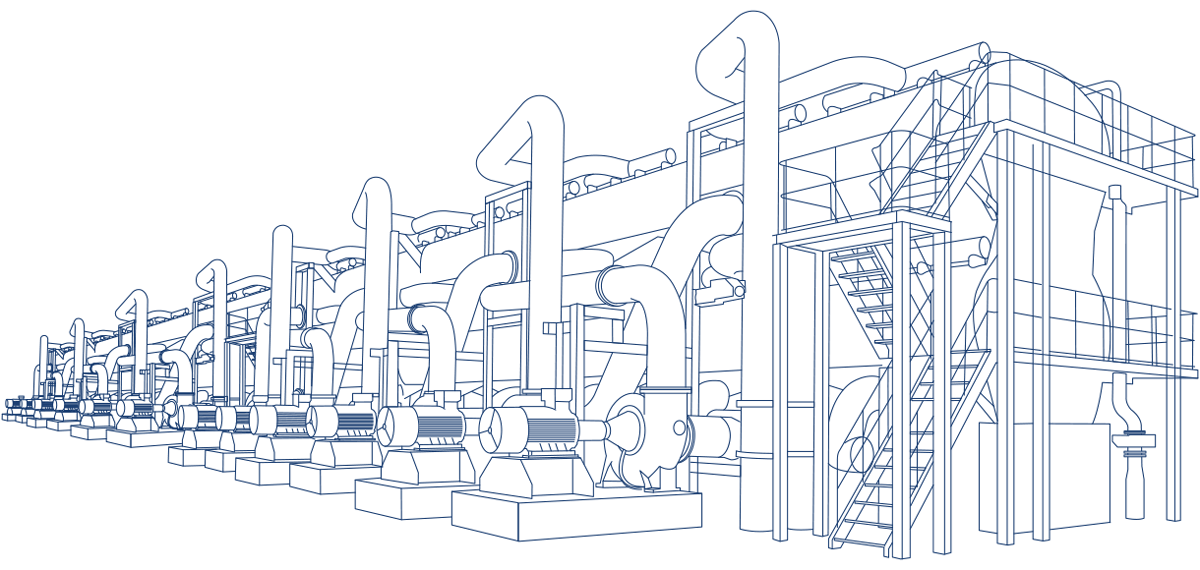

Stock Preparation

With the innovative stock preparation products of the BlueLine family, customers profit from proven Voith quality and at the same time lower costs for energy, fiber, water and maintenance as well as enhanced runability and safety.

Visit the product page

Voith’s extensive product and process know-how in the field of OCC is unique in the industry. It allows paper manufacturers to optimize their entire recovered paper stock preparation by maximizing both efficiency and quality.

Visit the product page

For the manufacture of products based on virgin fibers, Voith offers its customers integrated solutions for an efficient and sustainable paper manufacturing process. Experienced experts design customized systems for a wide range of requirements and paper grades, from tissue to specialty papers, board and packaging.

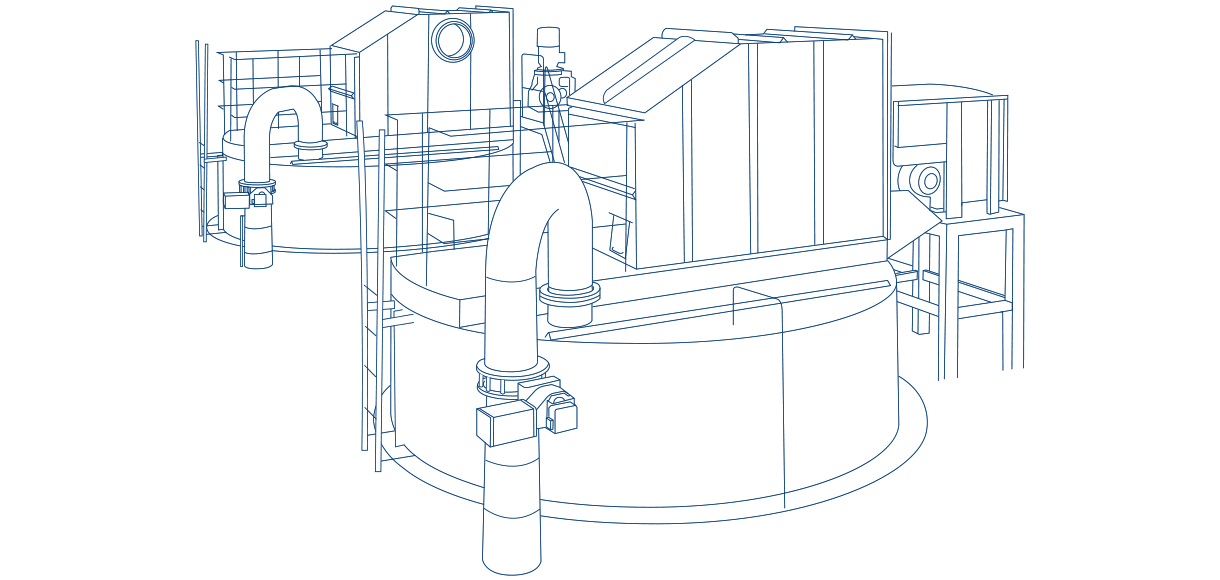

Visit the product pageAchieving sustainable reduction of fresh water consumption is one of the key challenges in the development and operation of production facilities. With Voith's professional AquaLine water management solutions, significant water savings are realized leading to more sustainable paper production.

Visit the product page

Raw Material Handling

Pulping

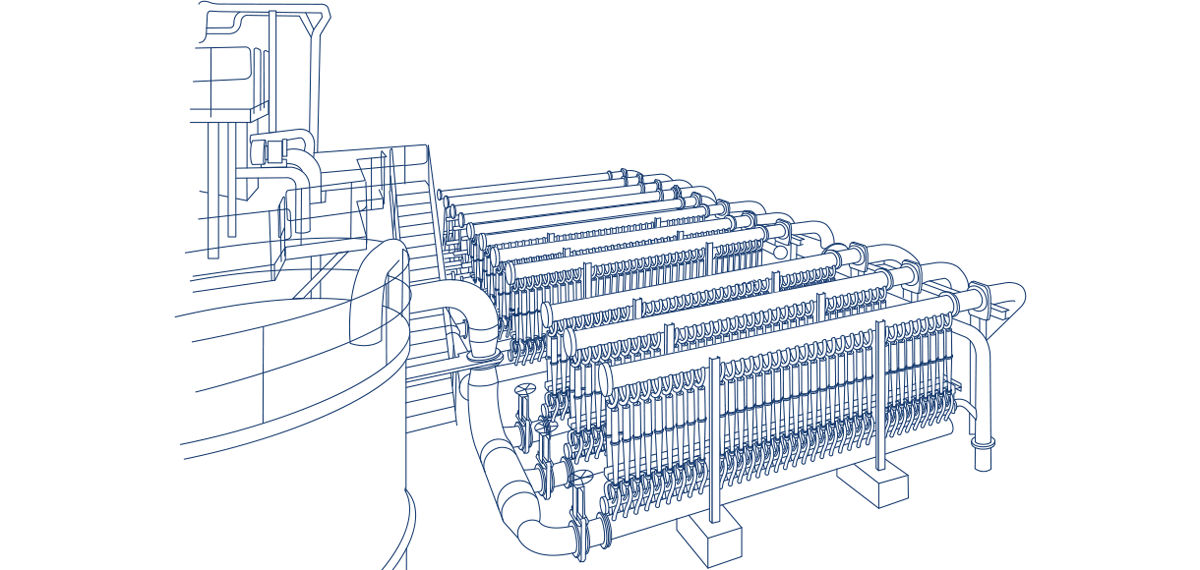

Cleaning

Screening and fractionation

Flotation

Refining and deflaking

Compact Dispersion System

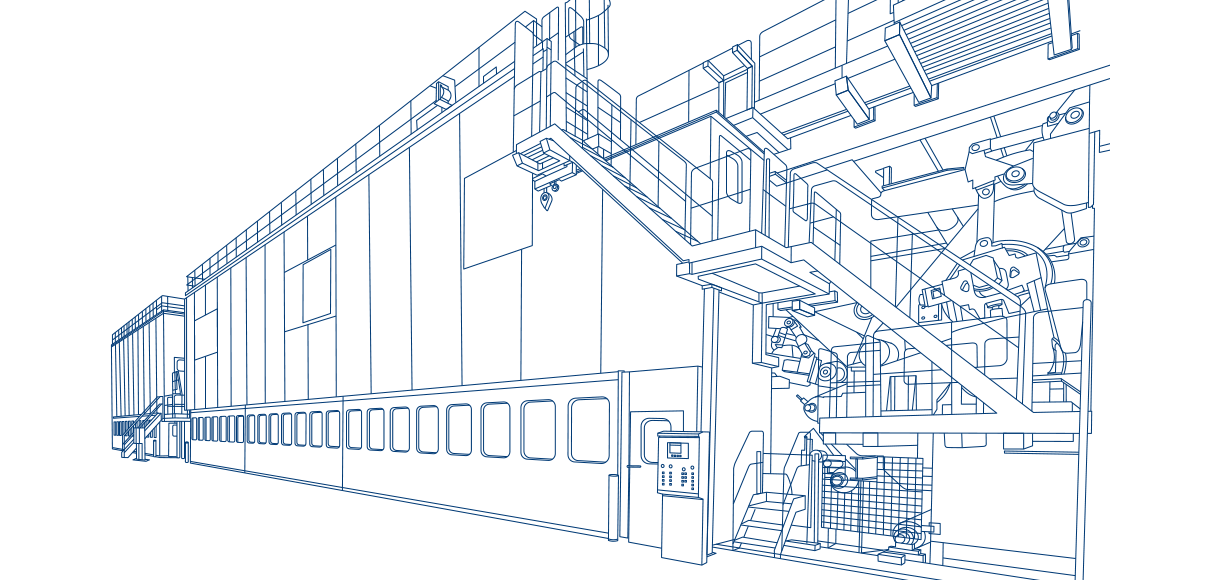

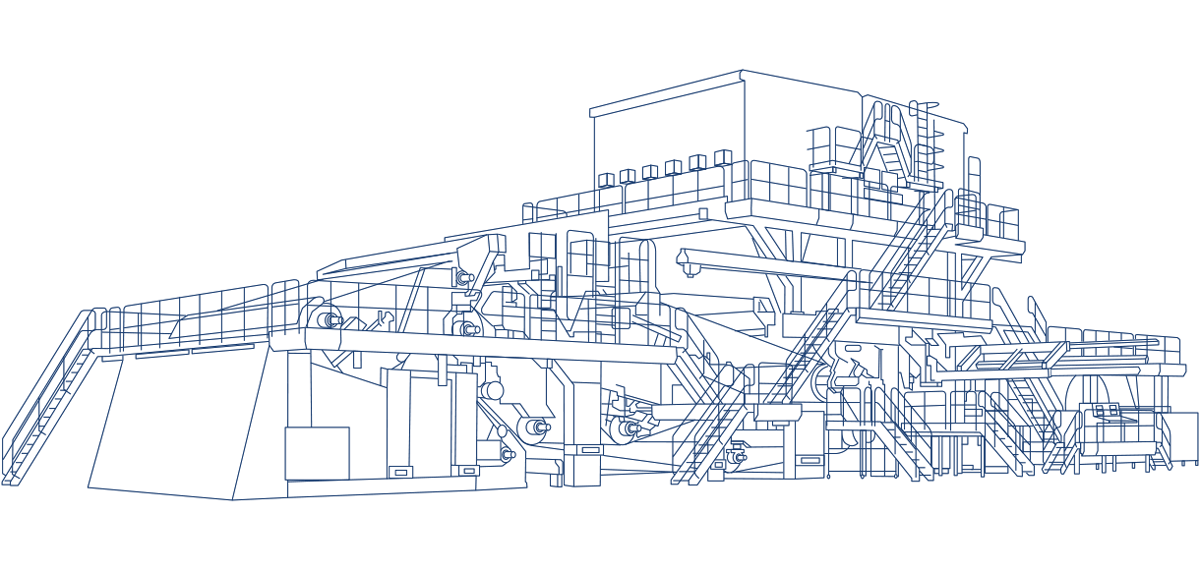

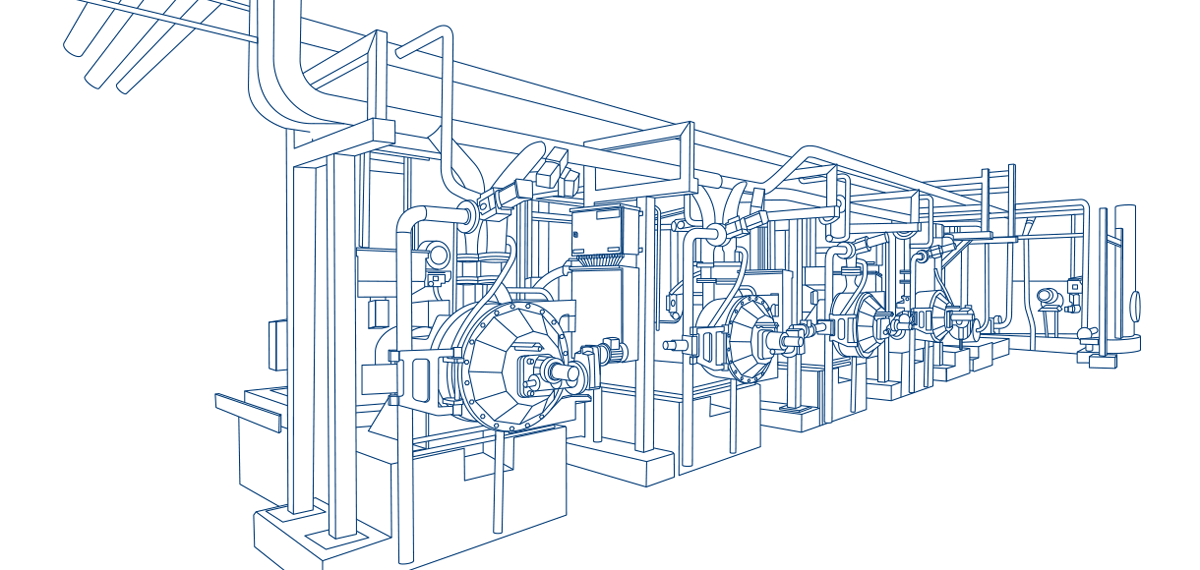

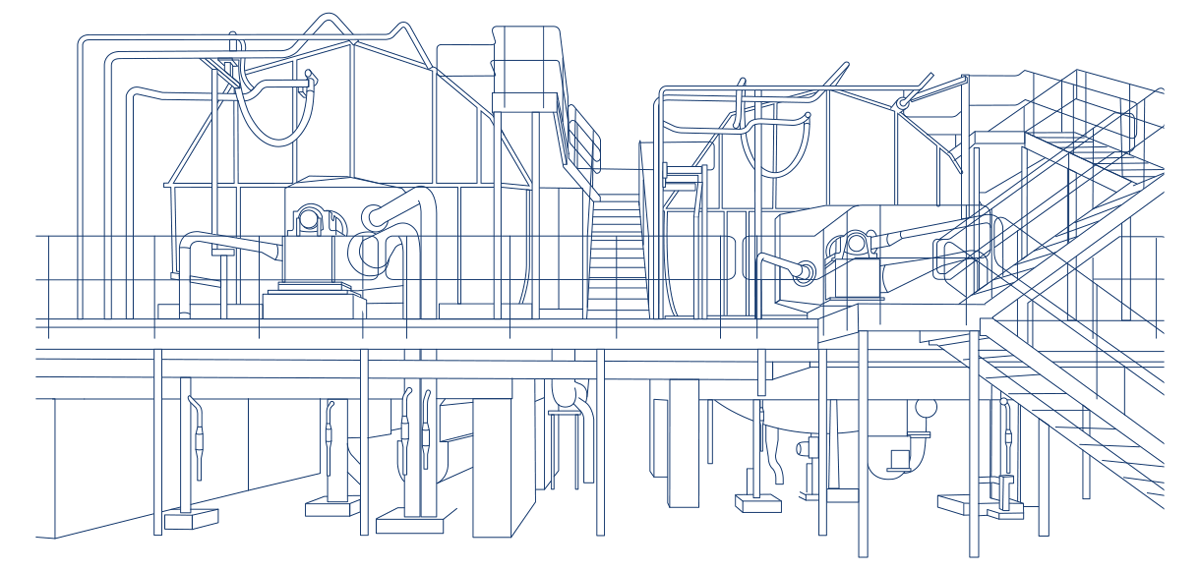

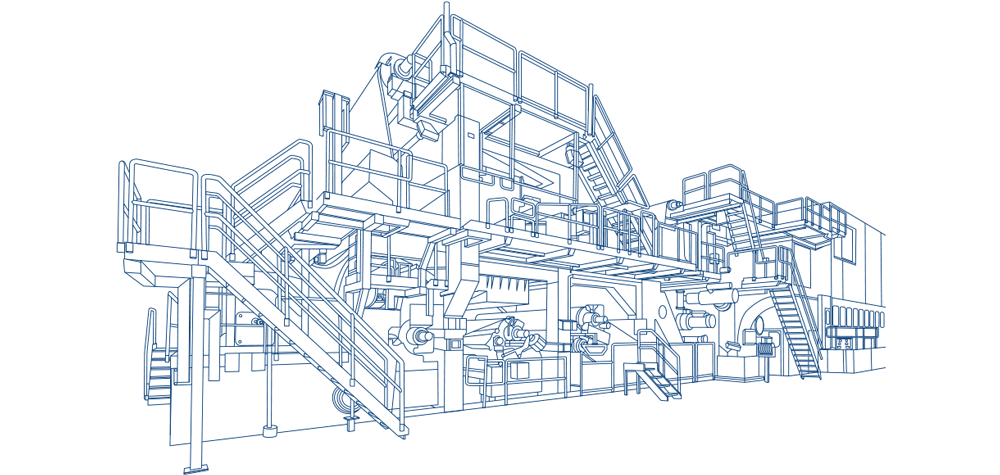

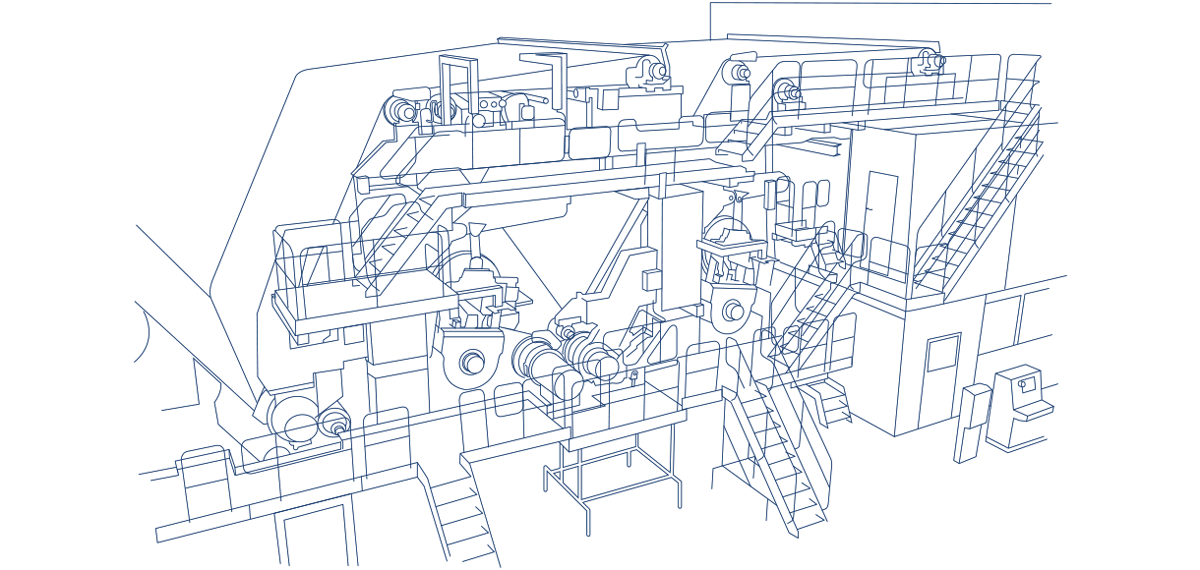

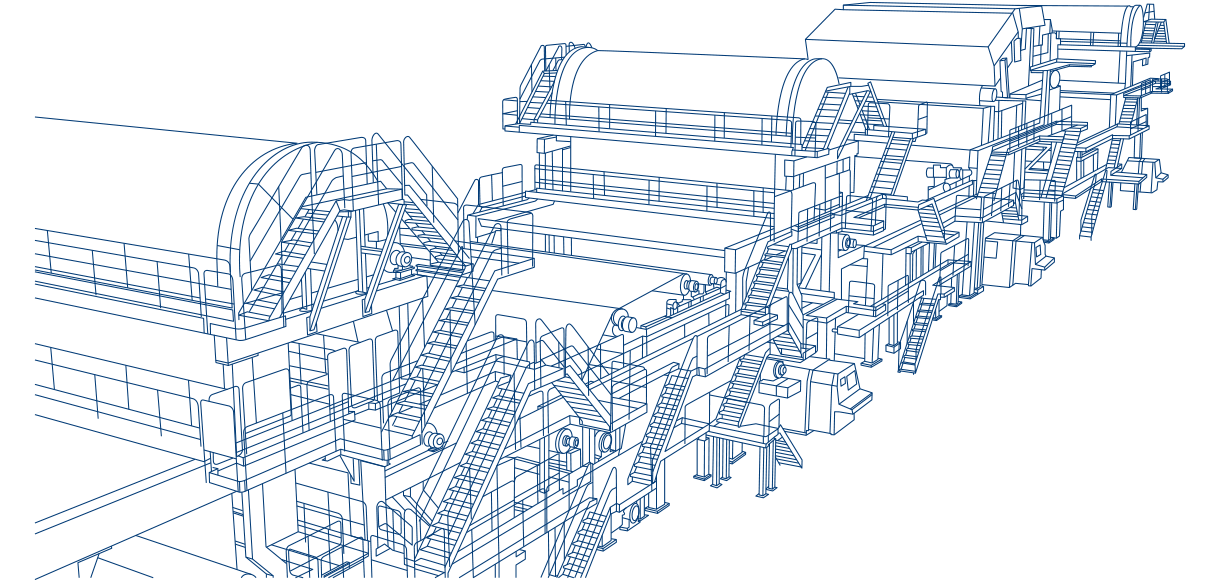

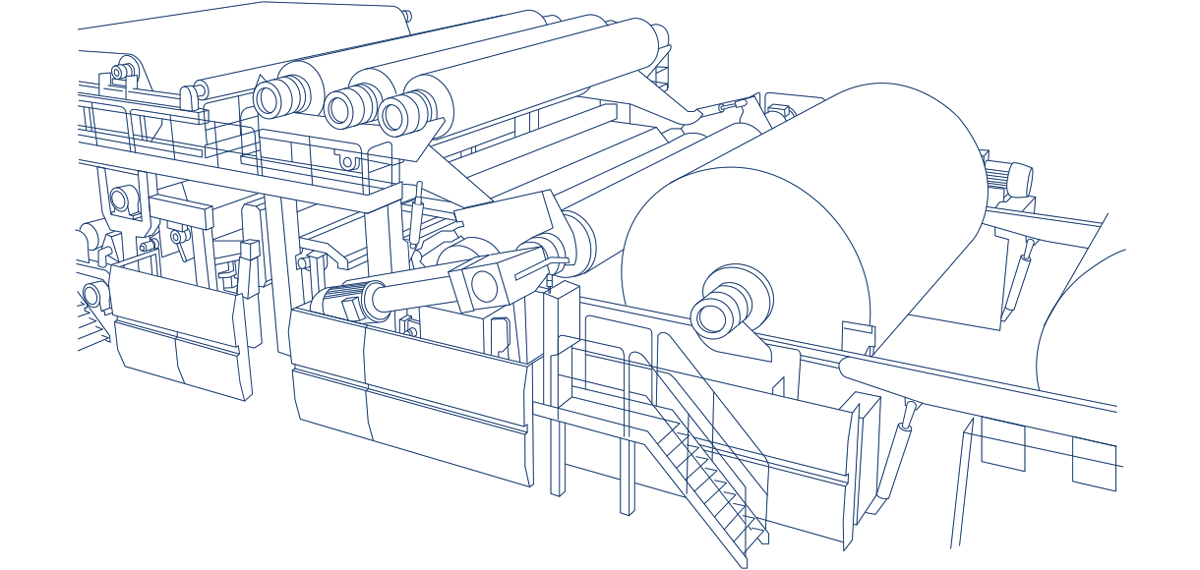

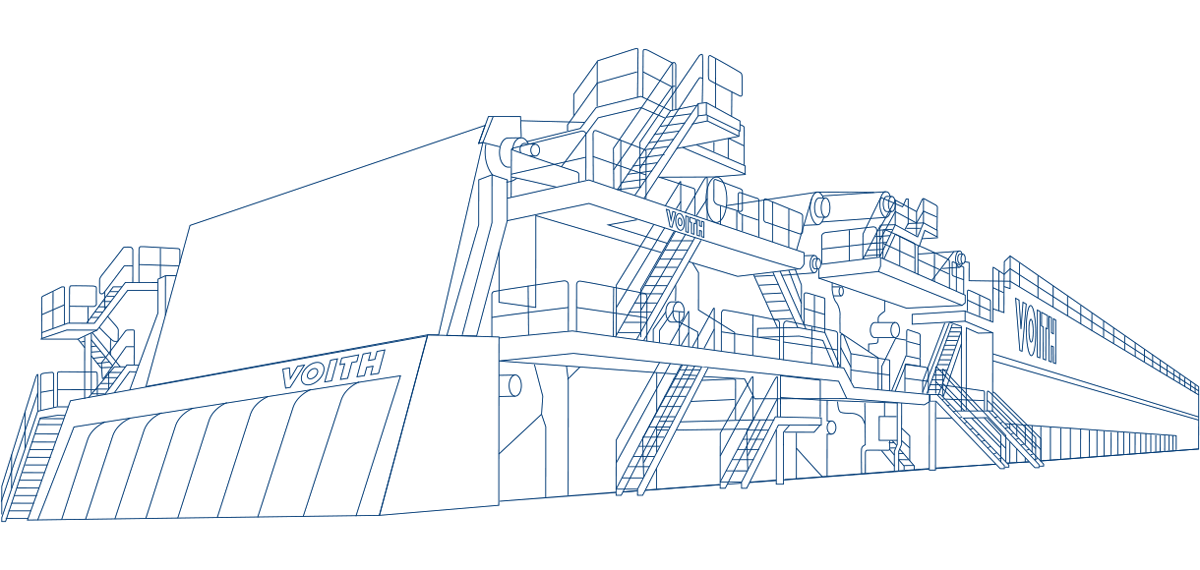

Paper Machine

With XcelLine paper machines, Voith offers efficient paper production of every paper grade on a new level. All single components, technologies and services are perfectly coordinated and integrated. Their interplay leads to excellent performance over the entire lifecycle of the paper machine. Perfect design, coordination and reliability of all secondary systems are also part of Voith’s scope of supply.

Visit the product pageAchieving sustainable reduction of fresh water consumption is one of the key challenges in the development and operation of production facilities. With Voith's professional AquaLine water management solutions, significant water savings are realized leading to more sustainable paper production.

Visit the product page

Due to inefficient threading processes, up to 60 minutes of production time can be lost after each break and startup. In addition, there is often a safety risk for personnel who must undertake a manual intervention in this process. Therefore, we have developed PrevoSystems, fully automated threading and cutting systems.

Visit the product page

MasterJet Pro

Forming concepts

Press concepts

Drying concepts

Calendering concepts

Reeling concepts

Voith winders

Sustainable Solutions

Discover our solutions for sustainable and cost-efficient production

TissueForm ITY

TissueForm ITY

TissueFlex XD

TissueFlex XD

- By replacing the competition felt with TissueFlex XD we were able to reduce the gas and electrical energy consumption of the hoods and achieve better moisture profiles.

- By replacing the competition felt with TissueFlex XD we were able to increase the dryness after press by 1%, resulting in ~ 4% drying energy consumption.

MatchSoft

MatchSoft

Evolution

Evolution

+Peak

+Peak

OnEfficiency.DIP

OnEfficiency.DIP

The DIP quality fluctuations created by incoming raw materials or production changes are reduced by dynamic adjustment of the losses at the washing/flotation as well as real-time optimization of the bleaching chemicals dosage.

AquaLine Zero

AquaLine Zero

FlowJec

FlowJec

CleanLine Extract 4D

CleanLine Extract 4D

SolarPress

SolarPress

VForm

VForm

HydroSeal

HydroSeal

HelioX

HelioX

DuoDry CC

DuoDry CC

EcoHood 65

EcoHood 65

xSteam Pro

xSteam Pro

CleanLine Excell

CleanLine Excell

EdgeExpert

EdgeExpert

DuoShake DG

DuoShake DG

qDry Pro

qDry Pro

DynaLayer

DynaLayer

Web stabilizers

Web stabilizers

EvoDry

EvoDry

EcoChange W

EcoChange W

MasterJet Pro

MasterJet Pro

AquaLine Zero

AquaLine Zero

BlueLine DIP process

BlueLine DIP process

BlueLine OCC process

BlueLine OCC process

IntensaPulper IP-V

IntensaPulper IP-V

LowEnergyFlotation (LEF)

LowEnergyFlotation (LEF)

MultiFoil rotor

MultiFoil rotor

HiCon 2.0 technology

HiCon 2.0 technology

IntensaScreenDrum

IntensaScreenDrum

IntegraScreen

IntegraScreen

EclipseR Rotor

EclipseR Rotor

Pluralis

Pluralis

EcoMizer

EcoMizer

C-bar baskets

C-bar baskets

Star Rotor

Star Rotor

FloWing

FloWing

TheWall

TheWall

BaglessPlus

BaglessPlus

InduraClean

InduraClean

CleanLine Excell

CleanLine Excell

HydroSeal

HydroSeal

Servolution

Servolution

FilmLube

FilmLube

+Up

+Up

- With +Up, your tissue machine starts up an average 50% faster than with standard felts.

- The Efficiency Add-On +Up generates benefits of up to 100,000 €/year in additional production volume.

- It is 100% compatible with all felts in tissue, for example, Infinity, TissueFlex and Evolution.

More relevant products and solutions

Contact us

Read our customer magazine for the paper industry

Mission Zero: The current issue of our nextlevel Magazine takes you down a greener papermaking path and showcases how Voith Paper is setting standards for a more sustainable paper industry.

Read the magazine nowLatest news about Voith Paper

Voith Paper Newsletter

Always get the latest updates on new products and services, projects, campaigns and success stories as well as upcoming exhibitions and conferences – straight to your inbox.

Subscribe now