BlueLine Stock Preparation

Environment. Quality. Reliability.

With the innovative stock preparation products of the BlueLine family, customers profit from proven Voith quality and at the same time lower costs for energy, fiber, water and maintenance as well as enhanced runability and safety.

Discover the BlueLine Product Portfolio

Please Select a Process Step

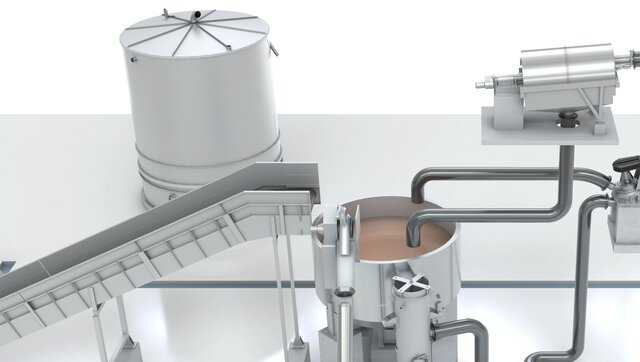

Pulping

The suitable technology for each resource

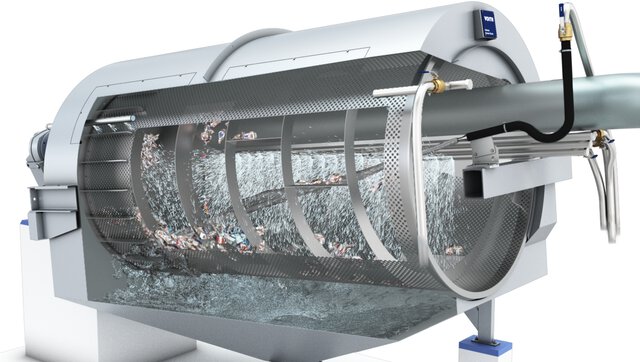

IntensaDrum Duo is a two-piece drum pulper for stock preparation system with high production. The machine design is based on our succesfull IntensaDrum and implements the long experience of Voith drum pulpers. Higher than standard pulping consistency and efficient screening process are key points adding to a long list of benefits with the IntensaDrum technology. In addition, modular components transfer the IntensaDrum Duo technology and reliability to a new level.

PRODUCT DETAILS

IntensaDrum is a pulping drum for efficient pulping. It performs in a consistency range of 15% to 20%, gently pulping the paper and separating the fibers from contaminants.

Product Details

LC Pulping system for recovered paper containing IP-R, JM, IPU, IM, ISD, ZW3. Only an appropriate sized LC-Pulping system with the required selection of machines results in an optimal pulping technology. This can be selected depending on the type of furnish, production and the contaminant included in the furnish.

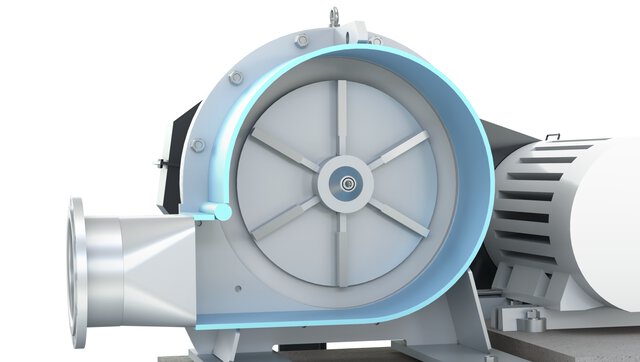

Highly contaminated stock flows in the pulping system for recovered paper can only be pumped reliably and largely free of blockages using a special pump. Whether in LC or HC system, IntensaPump pumps the critical contaminants to the next machine very reliably in both systems, BluePulpLC and BluePulpHC. Featuring large nozzle diameters and a free-flow impeller, IntensaPump is designed for plug-free pumping of stock flows with a high proportion of contaminants. The impeller has a long service life thanks to its hard facing. A frequency converter offers the possibility for optimized pump speed and reduced energy consumption for intermittent pumping operation.

Product Details

The IntensaMaXX pulper detrashing machine prevents any stringings and therefore allows for the maximum concentration of contaminants. Fiber loss is reduced to a minimum through a washing cycle.

Product Details

IntensaPulper facilitates efficient pulping of fibers from virgin pulp, recovered paper or paper machine broke in stock preparation.

Product Details

The IntensaScreenDrum is a newly developed drum screen for efficient reject washing with minimum fiber loss. Thanks to a closed hood the cleanliness of the pulper area and thus safety is improved.

Product detailsCleaning

Removal of contaminants with minimal fiber loss

To minimize fiber loss, the rejects have to be processed in subsequent cleaner stages. There are two or three cleaner stages in Voith's recovered paper systems. In the approach flow system, no more than four stages are required.

InduraClean is a modular system for heavyweight cleaning that consists of a redesigned cleaner bank and various cleaners that are perfectly matched to one another. Depending on process requirements, the system can focus on production volume, energy consumption, or separation efficiency.

InduraHiClean is a high-consistency cleaner that removes abrasive contaminants directly after the pulper. With the use of IDH cleaners, the wear of machines located downstream in the process – such as screens or deflakers – can be minimized.

For stringent removal efficiency requirements, the InduraHiClean cleaners can be combined in a two-stage protector system called InduraPro. Even small stones or sand can be separated with this system.

Product DetailsScreening / Fractionation

Removal of undesirable contaminants

The flow-optimized machine housing results in constant flow and pressure conditions around the basket. Together with the use of the experienced Voith rotors and screening baskets, a high sticky reduction is achieved.

Product Details

The homogeneous screen passing velocity reduces the formation of deposits or stringings in the sorter.

Product Details

IntegraCombisorter is a continuously operated, highly efficient reject screen for separating plastics and light rejects. It provides high yield with minimum fiber loss. Thanks to the very high consistency in the reject discharge, no other thickening machine is required.

Product DetailsFlotation

Improve optical cleanliness

Selectivity is important for retaining useful material such as fibers in the accepts. The selectivity criteria is the wettability of the particle surfaces. The more hydrophobic the particle surface, the better it adheres to an air bubble and the better the chance of its removal.

The InjectaCell flotation system removes contaminants from the stock suspension with minimal fiber loss. Due to the two-stage design, the flotation process is extremely efficient.

Product Details

InjectaCell Compact achieves high savings in investment and maintenance in flotation through eliminating the secondary flotation cell.

Product Details

InjectaPump guarantees stable operation, even with highly varying foaming behavior and changing amounts of foam. Since it combines foam destroyer, subsequent de-aeration and pump all in one machine, the investment cost is low.

Product DetailsWashing / Thickening / Dewatering

Thickening is important for increasing the stock consistency as required for further processing, minimizing storage volumes and for water loop separation. With the dewatering process, the stock consistency is increased from about 5 to 30% or more to prepare for the next process stage and for complete water loop separation.

InfiltraScrewpress is part of the Compact Dispersion System in stock preparation. The system provides reliable operation with only three machines.

Product Details

InfiltraDiscfilter is the latest generation in dewatering without filter bags. Through a combination of proven technologies, the suspension can be dewatered reliably and almost maintenance-free.

Product Details

The Thickener EFK is a solid and flexible all-rounder. It is suitable for thickening pulp prior to a screw press or storage chests. In the broke preparation, it evens out consistency fluctuations, enhances storage capacity and thus contributes to stable paper machine operation.

Product detailsDispersion / Bleaching

Reduce unwanted contaminants and improve optical characteristics

Bleaching improves the optical characteristics of the stock. The brightness is increased with the penetration of chemical additives by bleaching the fibers and colour stripping as well as moving the colour spectrum.

InfibraDisp is part of the Compact Dispersion System in stock preparation. The system provides reliable operation with only three machines.

Product Details

SpeedHeater is part of the Compact Dispersion System in stock preparation. The system provides reliable operation with only three machines.

Product DetailsRefining / Deflaking

Improved stock quality through effective fiber treatment

Voith is the market leader for compact disk applications in the field of fiber treatment. Disk applications provide very good accessibility, enabling a fast and secure filling change with low downtimes.

The InfibraFiner provides next generation refining by combining cutting-edge technology, highest capacity, ultra-modern industrial design, and digitalization.

Product detailsThe perfect stock preparation for packaging paper

Customers all over the world rely on Voith BlueLine systems for OCC stock preparation. The reason: Stock preparation contributes to a large extent to excellent paper quality. The technologically leading solutions set benchmarks in efficiency and quality and have proven themselves in countless applications worldwide.

The perfect stock preparation for all virgin fiber-based papers

For the manufacture of products based on virgin fibers, we offer our customers integrated solutions for an efficient and sustainable paper manufacturing process. Our experienced experts design customized systems for a wide range of requirements and paper grades, from tissue to specialty papers, board and packaging.

Get in Contact with Us

We Will be Pleased to Advise You

Voith Paper Newsletter

Always get the latest updates on new products and services, projects, campaigns and success stories as well as upcoming exhibitions and conferences – straight to your inbox.

Subscribe now