Pilot operation facilities: get the full potential of your application

Voith Paper Technology Centers worldwide are available for customers to pre-test equipment prior to purchase and help Voith engineers to analyze the efficiency and potential of their R&D activities.

The Technology Centers are constantly updated with the latest machinery and pioneering production processes for the pulp and paper industry. From stock preparation, different paper machine configurations, coating units and calenders to the reel, new configurations can be tested. To minimize investment risks, we thus offer you the opportunity to assess the potential of a new machine or new technologies. All of our facilities are designed to be fully flexible so we can respond to your precise demands.

Your benefits of the Voith pilot facilities

- Testing and comparing of process and machine concepts

- Optimization of raw materials and their treatments for different paper grades

- Determination of operating parameters for start-up preparation

- Minimization of investment risk with process test under realistic conditions

- Development of new processes and products to generate unique selling points

- Troubleshooting of your process without affecting production

- Profit from our experts’ knowledge

- Employee training

Teaser

Detailed information on our modernized pilot coater

After entering your contact details, we will provide you our opening ceremony and our detailed brochure.

English

PORTUGUÊS

ESPAÑOL

Something went wrong. Please try again later.

Our Technology Centers

Fiber

Fiber Technology Center

The following process steps are available for your stock preparation trial:

|

|

Paper and Board

Paper and Board Technology Center

Trials can be performed on the following trial facilities:

- Pilot paper machine with two approach flow systems for multi-layer trials

- Pilot reel in industrial scale

- Headbox test rig

- Drying section

Coating

Coating Technology Centers

The following coating units are available at our pilot coater:

- Single and multi-layer curtain coater (DynaLayer)

- Film coaters (SpeedSizer)

- Blade or rod coater with free jet applicator (JetFlow F)

- Size press

In addition, small scale trials can be performed at our curtain test-rig.

Calendering

Calendering Technology Center

Our pilot calender (1x3 configuration) is equipped as follows:

- Soft and hard nip calender (EcoCal Soft/Hard/Plus)

- Moisturizer and steam boxes

- IR panel

- Climate chamber

We also offer trials at our calender test-rig.

Nonwovens

Nonwovens Technology Center

In the Nonwovens Technology Center, tests on the inclined wire simulate production conditions. By using our pilot plants, we ensure tailor-made machines that offer optimal performance at your facility from the first day. In addition, operating parameters can be determined to prepare for system commissioning at your paper mill. The clothing can also be tested and optimized beforehand.

Key physical parameters can then be measured and evaluated in the adjacent laboratory.

Laboratory

Laboratory

In addition to the standard measurements we offer:

|

|

|

|

|

|

Voith pilot operation facilities worldwide

Voith Paper Technology Centers worldwide provide the maximum flexibility. We help you to improve your products, develop new ones that meet your requirements, and fulfill your customers’ needs even further.

At the Specialty Technology Center in Düren, Germany, focus lays on wet-laid processes. Moreover, new forest-based and non-forest-based products can be developed and tested. Customers benefit from two pulpers, three machine chests, a refiner and deflaker that support the development of new wet-laid products.

- Wet-laid Nonwovens

- Bank Notes

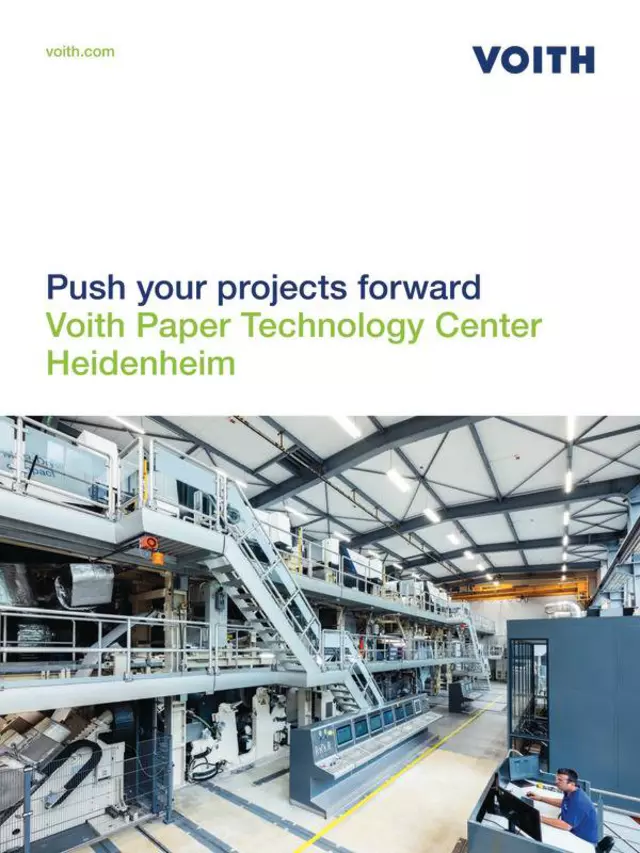

Technology centers in Heidenheim cover all stock preparation processes, paper machine testing as well as pilot coater and calender. Besides troubleshooting and the optimization of new processes, focus lays on the exploration of new furnish types, assistance in new product development and the comparison of different machine process concepts.

- Board & Packaging

- Specialty

- Graphic

- Stock Preparation

- Paper Machine

- Coating

- Calendering

Our trained experts at our Technology Center in Motomiya, Japan, support customers expecially from the APAC region and carry out trials regarding coating and stock preparation processes and new product developments.

- Coating

- Stock Preparation

Your contact to us

Would you like to learn more about our pilot facilities? We are happy to answer your questions.

Voith Paper Newsletter

Always get the latest updates on new products and services, projects, campaigns and success stories as well as upcoming exhibitions and conferences – straight to your inbox.

Subscribe now