Cleaning

Removal of contaminants with minimal fiber loss

To minimize fiber loss, the rejects have to be processed in subsequent cleaner stages. In Voith's cleaner systems, in most cases two or three cleaner stages are required but no more than four stages.

The modular cleaning system InduraClean consists of a redesigned cleaner bank and various cleaners that are perfectly matched to one another. Depending on process requirements, the system can focus on achieving a much higher production volume, a reduction of energy consumption, or a significantly improved separation efficiency.

The right machine for every task

| Feature | Process | |

| InduraHiClean | Single-stage cleaner |

High-consistency cleaning |

| InduraPro |

Two-stage cleaner with high separation efficiency |

High-consistency cleaning |

| InduraClean bank |

Cleaner bank with low footprint for all InduraClean cleaners |

Low-consistency cleaning |

| InduraClean IDC-4 |

Highly efficient heavyweight cleaner |

Low-consistency cleaning |

| InduraClean IDC-5 |

Full-stream heavyweight cleaner |

Low-consistency cleaning |

| Lightweight cleaner LT3 |

Light contaminant removal system |

Low-consistency cleaning |

Product range

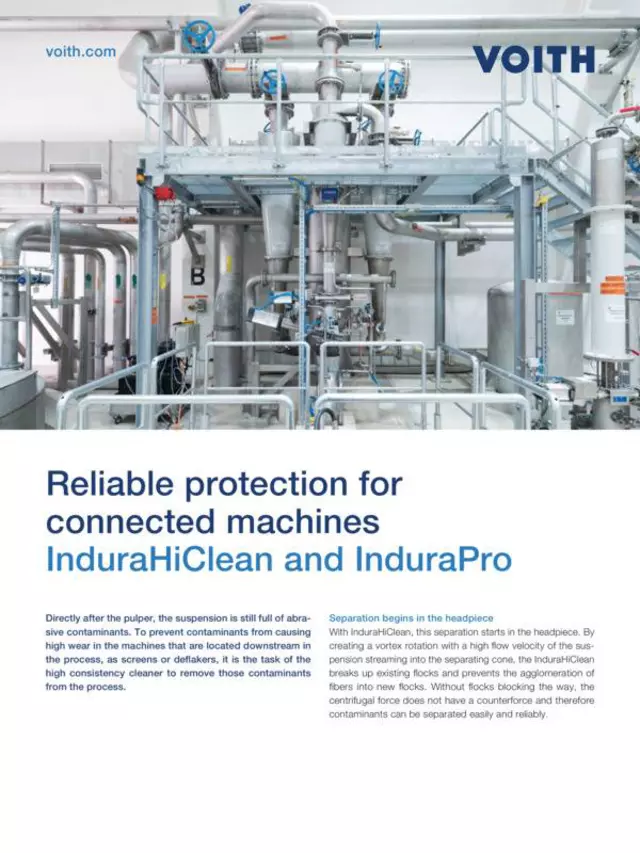

InduraHiClean

Reliable separation of abrasive contaminants

With InduraHiClean, the separation starts in the headpiece. In order to break up existing flocks and prevent the agglomeration of fibers into new flocks, the incoming suspension is put into a vortex rotation with a high flow velocity. Without flocks blocking the way, the contaminants can be separated easily and reliably.

InduraHiClean cleaners are available in a standard version as well as a particularly wear-resistant version for high contaminant loads. The bottom cone, vortex breaker and reject trap are interchangeable between most cleaner sizes. Thus, the number of spare parts needed can be reduced, and in case of a high capacity increase, the number of new parts required is minimized. Thanks to the unique Vortex Breaker, no contaminants are rotating on the top valve of the trap during the discharge time. Thus, the life of the valves can be increased significantly.

For stringent separation efficiency requirements, the InduraHiClean cleaners can be combined in the two-stage protector system InduraPro.

The BlueLine product range from Voith comprises modern machines and products for stock preparation that are characterized above all through the efficient use of energy and other raw materials and by gentle treatment of the fibers.

BlueLine Advantages

Reduced Fiber Loss

Reduced Fiber Loss

Lower Maintenance Cost

Lower Maintenance Cost

InduraPro

Separation efficiency for most stringent requirements

In the InduraPro system, two cleaners in the first stage operate with a continuous reject flow. The reject is sent via a sedimentation tank to discharge heavy containments and a booster pump into the second stage. Here, the fibers are separated from the reject and fed back into the process. Due to the small diameter of the second stage, even particles like small stones or sand can be separated, and the separation efficiency is increased significantly.

The BlueLine product range from Voith comprises modern machines and products for stock preparation that are characterized above all through the efficient use of energy and other raw materials and by gentle treatment of the fibers.

BlueLine Advantages

Reduced Fiber Loss

Reduced Fiber Loss

Lower Maintenance Cost

Lower Maintenance Cost

InduraClean bank

High throughput with reduced footprint

The BlueLine product range from Voith comprises modern machines and products for stock preparation that are characterized above all through the efficient use of energy and other raw materials and by gentle treatment of the fibers.

BlueLine Advantages

Higher Runability

Higher Runability

Lower Maintenance Cost

Lower Maintenance Cost

InduraClean IDC-4

Optimum cleaning efficiency for any application

The InduraClean concept has a modular structure, which means that the cleaner can be easily adapted to the customer’s individual requirements and production targets.

- The IDC-4F (FourFlow) was specially developed for large production capacities and is used primarily in the production of board and packaging papers.

- The InduraClean IDC-4Q (FourQuality), on the other hand, is mainly suited to specialty and graphic paper grades, because it prioritizes very high cleaning efficiency and quality.

In addition to the installation of the new cleaner banks, Voith also offers the fast rebuild of existing banks. Voith provides support both in system planning and installation as well as commissioning and service for optimum results. The new cleaners can also be integrated into banks from other manufacturers.

The BlueLine product range from Voith comprises modern machines and products for stock preparation that are characterized above all through the efficient use of energy and other raw materials and by gentle treatment of the fibers.

BlueLine Advantages

Higher Runability

Higher Runability

Reduced Fiber Loss

Reduced Fiber Loss

Lower Maintenance Cost

Lower Maintenance Cost

Lower Energy Consumption

Lower Energy Consumption

InduraClean IDC-5

InduraClean IDC-5I

Maximum effectiveness and the least fiber loss

With stock consistencies of up to 3%, InduraClean IDC-5I achieves the highest separation effectiveness thanks to its smooth inner surfaces and flow-optimized head piece. Cones made of plastic or wear-resistant ceramic flexibly adapt to the concentration of contaminants that are present. Due to the high concentration of contaminants in the reject, fiber loss is low. In addition, the EcoMizer dilution and continuous overflow ensure obstruction-free and low-pulsation operation in all stages, even with the highest stock consistencies.

InduraClean IDC-5C

Removal of contaminants with low specific weight

Paper mills that encounter lightweight rejects in their stock can use the LightPlus upgrade, which is suitable for HC5, HCH5 and HCL5 cleaners to a combined system for heavy and lightweight rejects. The upgrade is a great value alternative to a large investment in extensive new lightweight cleaning systems.

The BlueLine product range from Voith comprises modern machines and products for stock preparation that are characterized above all through the efficient use of energy and other raw materials and by gentle treatment of the fibers.

BlueLine Advantages

Higher Runability

Higher Runability

Reduced Fiber Loss

Reduced Fiber Loss

Lower Energy Consumption

Lower Energy Consumption

Lightweight cleaner LT3

Reliable separation of lightweight contaminants

The lightweight cleaner LT3 is used in stock preparation and in the approach flow system to remove specific light contaminants from the suspension. It is also used for post-cleaning of the Combicleaner light reject and gas reduction.

Your benefits with Lightweight cleaner LT3

- No wax bleeding in final product

- Reduced Styrofoam content

- Reduced air content

Your contact - How can we help you?

Engineered for success

Servolution. Service at the next level

At Voith, the success of the customer takes center stage. Service means delivering customized service solutions and utilizing our full expertise to help our customers reach their goals.

Publications

-

Maximum flexibility and superior cleaning efficiency – InduraClean

PDFEnglish German Portuguese Spanish

News

Explore other relevant products and solutions

Voith Paper Newsletter

Always get the latest updates on new products and services, projects, campaigns and success stories as well as upcoming exhibitions and conferences – straight to your inbox.

Subscribe now