Maximizing power density

As the current generation of turbo gearboxes approach their operating limits, an innovative design provides new levels of performance and the potential to debottleneck entire drive trains. BHS power distribution gear units from Voith offer a reliable, powerful, and durable solution for your high power density requirements.

Features and benefits at a glance

- Long service life

- Custom-tailored to your requirements

- Operational reliability, i.e., minimal unplanned stoppages of the drivetrain

- Reduced operating costs and CO2 emissions

- Excellent price-performance ratio

- Utilized in extraordinarily high-speed and power ranges

- Long service life as a result of the power-splitting principle

- Low maintenance and inspection requirements

- High-quality gear toothing

- Minimized noise level as a consequence of unique gear profiles

For high rotational speeds and high power

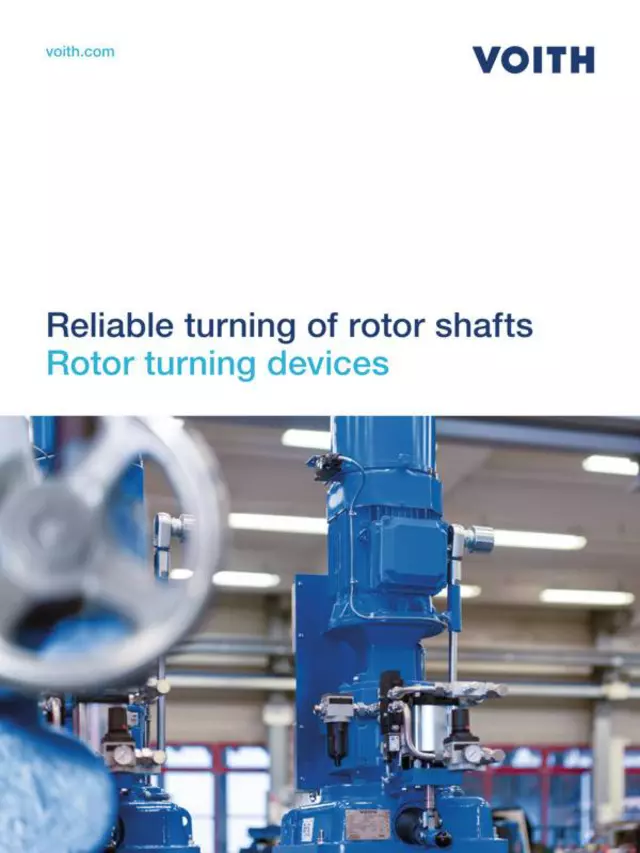

Power distribution gear units are primarily used in situations that exceed the technical limits of what other gear units can handle. An example of this includes machine drivetrains with gas turbine-driven turbo compressors requiring high rotational speeds and power. As a complex and powerful gear unit, they unite the simple, robust construction of a parallel shaft with the power branching options offered by planetary gear units.

Technical features

Transmitting power of up to 170 MW or at speeds of up to 80,000 rpm, our Voith power distribution gear units convert torque in turbo-drive trains. Even under the harshest conditions, they achieve over 250,000 operating hours with up to 98 percent gear unit efficiency.

| Power transmission | up to 170 MW |

| Speed | up to 80,000 rpm |

| Efficiency | up to 98 % |

| Gear ratio |

up to i = 10 |

| Housing design |

welded, cast |

|

Toothing |

spur single-helical toothing double-helical toothing |

Product registration

In order to receive quick technical support in the event of service, we recommend registering your Voith product. You can scan the QR code on the product or click on the button below to register your turbo gear unit or component. Please provide us your contact details, the product name, the KVO number and optional the date of commissioning.

Register your product nowVoith Service - how can we help you?

- Everything from a single source: development, design, production – and service!

- Decades of product experience as an original equipment manufacturer and service provider

- Fast and smooth cooperation and best service thanks to a worldwide network of service locations

- Long-term partnership and planning security are guaranteed due to longstanding corporate stability

Publications

Show all publications

-

Powerful, efficient, reliable | Key components for combined cycle power plants

PDFEnglish Portuguese Russian -

-

-

-