Maximizing reliability with predictive maintenance

Proof of value in vibration analysis

| Industry | Energy |

|---|---|

| Facility | Biomass power plant |

| Use case | Steam turbine monitoring |

| AI models | 1 |

| Signals | 13 |

Challenge

We conducted a proof of value using offline data to identify the root cause of increased gear vibration in a biomass power plant. Steam extraction, part of a neighboring operation, seemed to affect the turbine’s gear vibration target signal. Correlations between steam extraction, changes in the generator output, pressure, and gear vibration fluctuations were analyzed. The steam turbine set was monitored to pinpoint the cause of high housing vibrations.

Added value from Voith

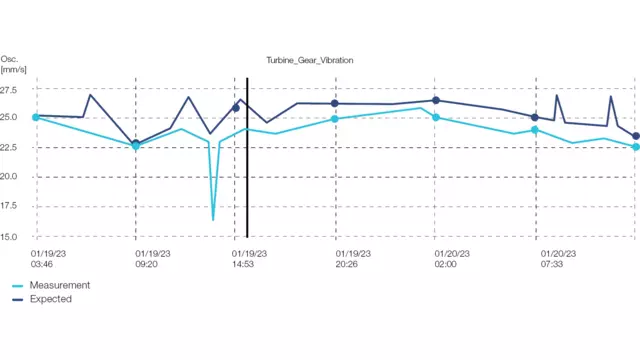

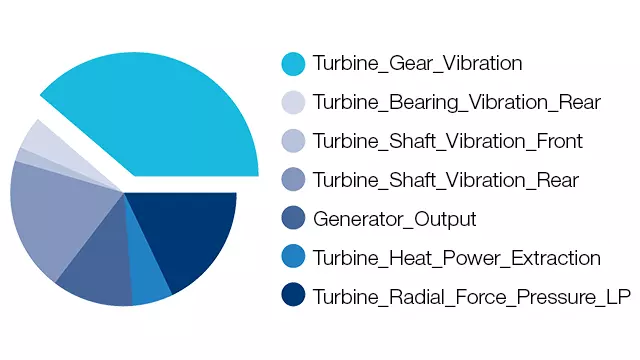

Gear vibrations were modeled as a target signal for operating states including summer, winter, steam extraction, and no steam extraction. Through root cause analysis, we identified which signals impact gear vibration (see Fig. 1). By adjusting turbine radial force pressure, turbine heat power extraction, and generator output – signals closely related to steam extraction – the rear shaft vibration can be controlled. This signal, in turn, significantly affects turbine gear vibration. By modeling the difference between measured and expected signals (see Fig. 2), we can determine the optimum steam extraction to positively influence target signals and reduce vibrations. Based on this analysis and the prediction of vibration levels, a steam extraction plan can be established to effectively control turbine gear vibration.