Preventing gearbox failure

Early anomaly detection

| Industry | Mining |

|---|---|

| Facility | Semi-autogenous grinding mill |

| Use case | Monitoring of motor, coupling, gearbox |

| AI models | 1 |

| Signals | 5 |

Challenge

A customer operates two different semi-autogenous grinding mill configurations: one driven by a variable frequency drive (VFD) and another using a standard setup with coupling and gearbox. The rotational speed of the semi-autogenous grinding mill with the standard arrangement should be variable, but the current configuration – which does not feature any Voith components – is experiencing failures. The goal is to identify the root cause of these failures and establish long-term monitoring of critical influencing signals.

Value proposition from Voith

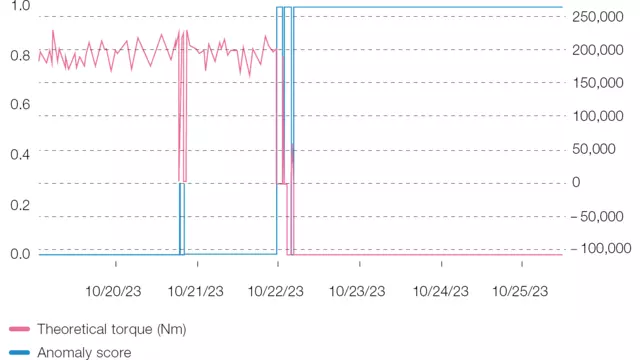

Using offline data modeled after a real-world scenario, we aim to demonstrate the maximum achievable performance and how to completely prevent failures in the drivetrain. The monitoring solution uses key signals such as power, feed rate, theoretical torque, and more to optimize performance and ensure the reliability of the semi-autogenous grinding mill.