Enhancing offshore efficiency

AI-powered predictive maintenance on FPSOs

| Industry | Oil and gas |

|---|---|

| Facility | Floating production storage and offloading unit (FPSO) |

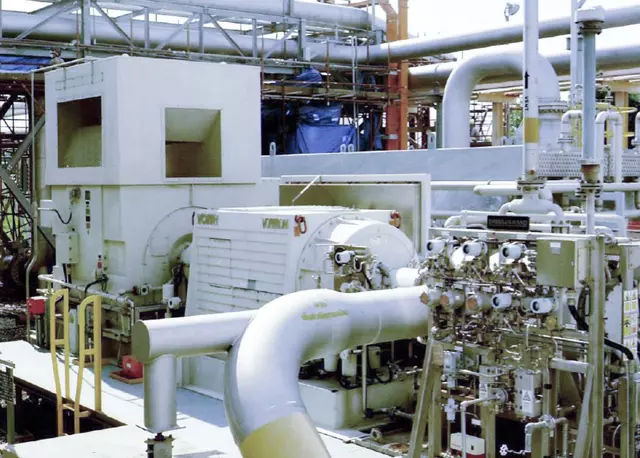

| Use case | Vorecon HP compressor drive |

| AI models | 1 |

| Signals | 29 |

Challenge

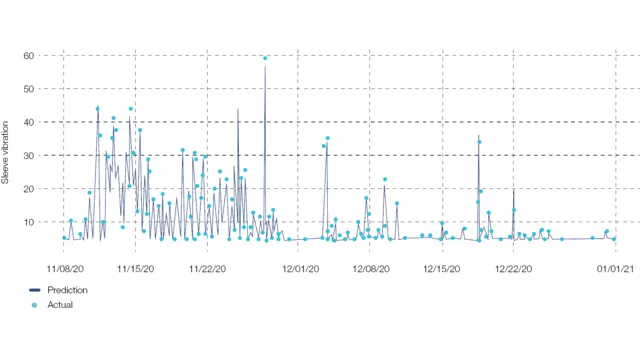

Voith aimed to demonstrate the potential of its AI solution for early detection of issues such as increased coupling sleeve vibration, which had previously caused a trip in a Vorecon at a floating production storage and offloading unit (FPSO) managed by a leading OEM collaborating with Voith. Voith is currently establishing a strategic partnership with this OEM to jointly develop and deploy advanced AI applications. Although the data provided was post-incident, an offline AI analysis was conducted to assess the system’s ability to identify anomalies and predict potential trips, illustrating the broad applicability and effectiveness of Voith’s AI in predictive maintenance.

Added value from Voith

Proactive maintenance with highly accurate AI models enables early anomaly detection to prevent downtime and damage. Root cause analysis provides data-driven insights by identifying key signals for optimized maintenance. This improved performance minimizes unplanned trips while maximizing efficiency. Voith found that the AI predictions for this use case were sufficiently accurate. It can therefore be assumed that the model would have detected the incident.

Voith partners with a leading OEM to harness AI for early anomaly detection and enhanced maintenance in oil & gas.