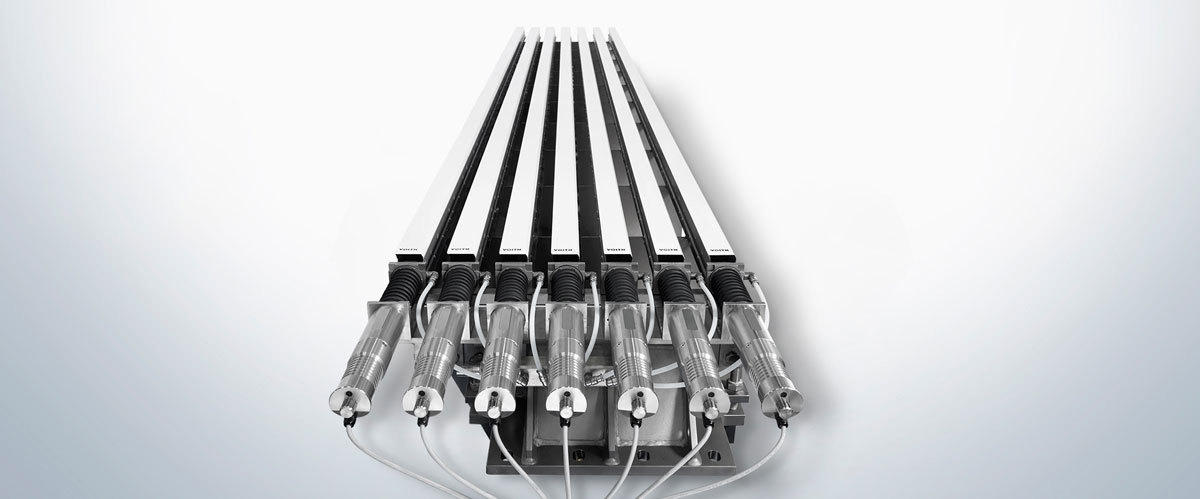

VForm hydrofoils – Increase the performance of your forming section

VForm hydrofoils allow individual adjustment of foil angle or height for each grade and basis weight. Thus, paper manufacturers benefit from maximum flexibility and an extended operating window. During a grade change, the hydrofoils can be adjusted automatically through the connection to the process control system.

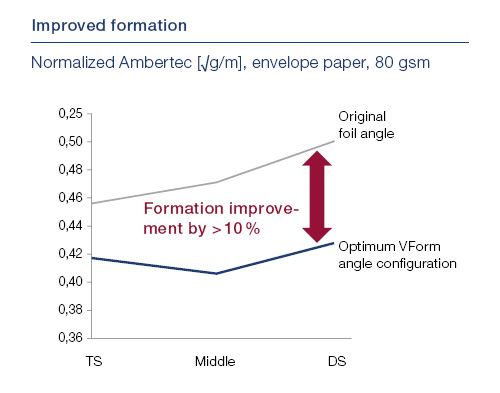

The optimal foil configuration can be stored for each paper grade thereby ensuring most efficient dewatering performance at any time. The individual adjustment of the hydrofoils also causes a higher activity of the fiber suspension. This promotes crucial parameters such as fiber orientation, formation and strength – and leads to higher paper quality.

Your benefits with VForm

- Maximum flexibility of foil adjustment

- Extended operating window with larger range of paper grades

- Better paper quality thanks to greater activity in the fiber suspension

- Increase in dewatering capacity

- Optional connection to ComCore platform

Most existing drainage boxes can be upgraded with VForm hydrofoils. Please do not hesitate to contact us – we will gladly check the individual optimization potential of your plant.*

Dr. Thomas Jaschinski

Ask your questions to our expert. He will contact you as soon as possible.

Impressions of VForm

Voith VForm – The 3-in-1 solution

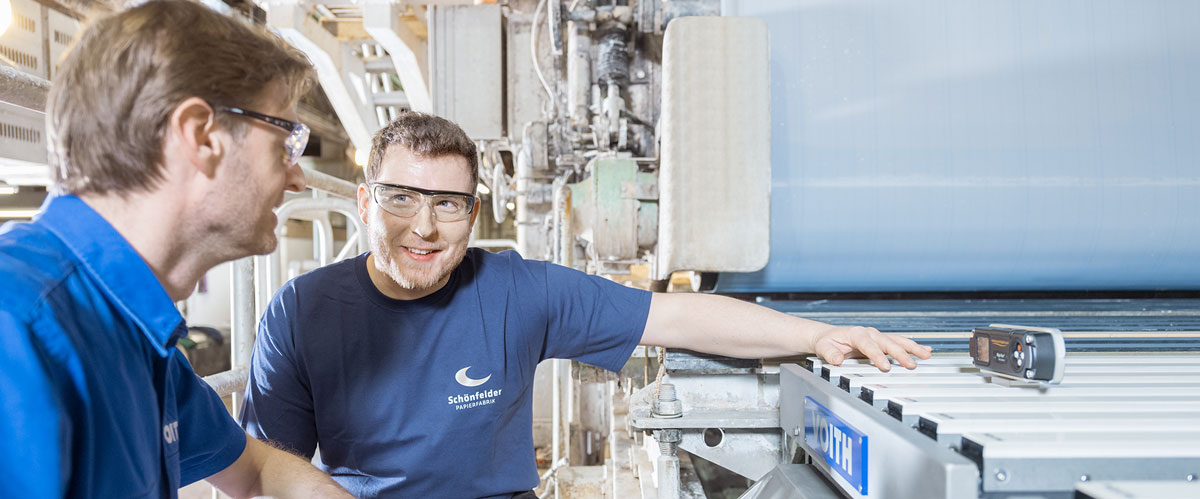

VForm operating successfully at Schönfelder Papierfabrik:

By retrofitting the PM 1 with VForm hydrofoils, Schönfelder Papierfabrik is responding to current market demands. The 3-in-1 solution ensures optimum dewatering in the forming section, even if changing between paper grades and basis weights frequently. So this traditional company gains more flexibility to adapt production to continuously changing demands.

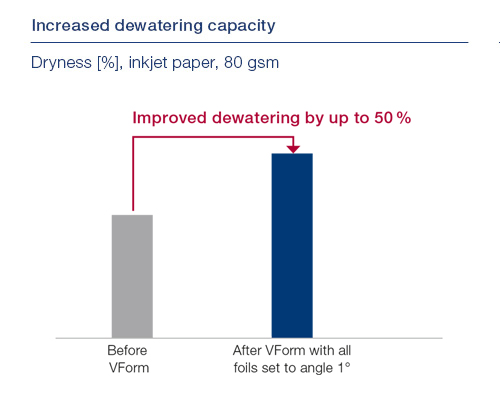

With respect to the PM 1 in Annaberg-Buchholz (Germany), Schönfelder has replaced three of the existing conventional boxes by two VForm hydrofoil boxes. By using VForm, dewatering performance in this area has increased by up to 50%.

„With the new VForm hydrofoil from Voith, we are achieving greater dewatering capacity and better formation. At the same time, we have been able to increase the static strength properties and obtain improved fiber orientation.”

Andy Diedrich, Production Manager at Schönfelder Papierfabrik

Schönfelder has decided to use electrically controlled VForm hydrofoils. “The ready-to-connect VForm hydrofoil boxes supplied by Voith are individually adjustable and could be easily integrated into the control system of our PM 1 with ComCore”, praises Mr. Diedrich. The optimal foil settings for each paper grade and each basis weight can be stored in the central process control system by Schönfelder and automatically retrieved during a production change.

“Through the use of VForm hydrofoils we are able to react flexibly to the increased market demands in the future.”

Andy Diedrich, Production Manager at Schönfelder Papierfabrik

This flexibility opens up an extended operating window with a larger basis weight range and also leads to an increase in production when producing higher basis weights.

* VForm hydrofoils with individual height adjustment are not available for the US market.