2022-02-21 Up to 50 percent less energy consumption with the new InduraClean heavyweight cleaning system

- Revised cleaner bank with modular, space-saving, flow-optimized design

- Significantly improved cleaning performance and cleaning volume as well as impressive energy and fiber savings

- InduraClean IDC-4F version is particularly suitable for very high production volumes of board and packaging papers, InduraClean IDC-4Q version achieves exceptionally high qualities for graphic and specialty papers

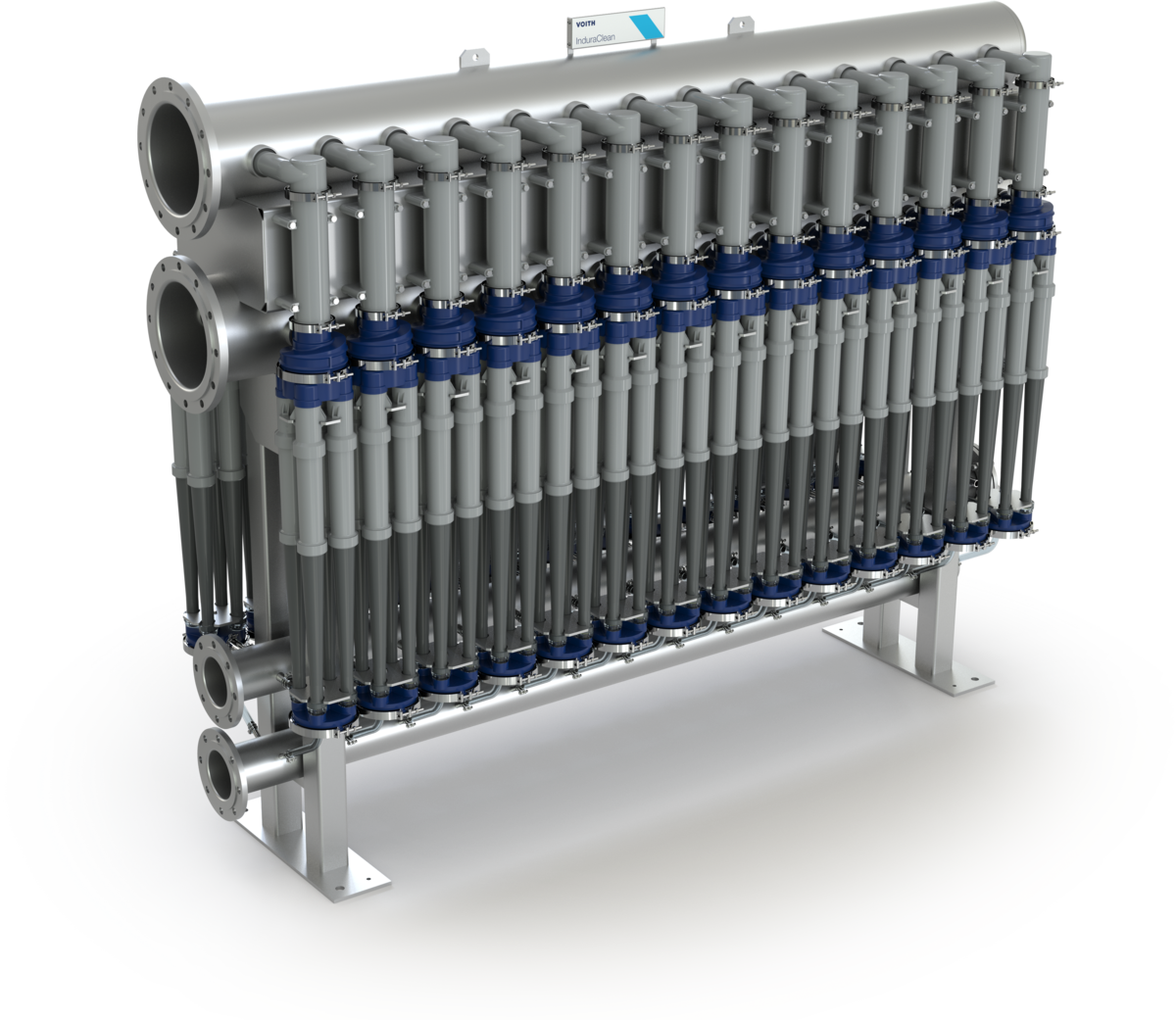

The modular, robust and optimized design of the new InduraClean IDC-4 can lead to significantly increased production, energy reduction of up to 50 percent or significantly improved separation efficiency, depending on customer requirements.

HEIDENHEIM. For optimized cleaning, Voith introduces the new InduraClean (IDC) product family as part of its BlueLine stock preparation portfolio. The system consists of an improved cleaner bank, which can be combined with both the new InduraClean IDC-4 and optimized InduraClean IDC-5. Depending on requirements, the focus of the modular cleaning technology can be on significantly increased production, energy reduction of up to 50 percent or vastly improved separation efficiency.

Naomi Voith

Global Communication Manager

t +49 7321 37-2209

Optimized cleaner bank and new cleaner design

The InduraClean IDC-4 combines four individual high-efficiency cleaners to enable high throughput with reduced space requirements. In addition, the cleaner bank features a flow-optimized design that avoids deposits in the cleaner bank due to rejects or heavily loaded grades.

Besides the revision of the cleaner connection, the bank has been extended to include an individual isolation. This means that individual cleaners can now be shut down during operation as needed.

Suitable design variants for individual customer requirements

There are two different versions of the InduraClean IDC-4 type, depending on the objective. The Voith experts designed the InduraClean IDC-4F (FourFlow) for large production capacities, especially for board and packaging papers. Meanwhile, the InduraClean IDC-4Q (FourQuality) is particularly suitable for specialty and graphic paper grades, as here the focus is on very high cleaning efficiency and quality. The new product family also includes the widely used cleaner type HCL 5 – now referred to as InduraClean IDC-5. Unlike the InduraClean IDC-4, it consists of only one cleaner cone. This proven system is also available with different configurations and with the option of lightweight separation.

In addition to the installation of the new cleaner banks, Voith also offers the fast rebuild of existing banks. Voith provides support both in system planning and installation as well as commissioning and service for optimum results. The new cleaners can also be integrated into banks from other manufacturers.

Find more information here: www.voith.com/cleaning.

The modular cleaning system InduraClean consists of a redesigned cleaner bank and various cleaners that are perfectly matched to one another. Depending on process requirements, the system can focus on achieving a much higher production volume, a reduction of energy consumption, or a significantly improved separation efficiency.

About the company

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

read more

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and supports customers in significantly reducing their carbon footprint. With its comprehensive automation products and leading digitization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art, digital technologies to increase the availability and efficiency of their systems in all areas of the production process.