2021-12-20 Papermakers benefit from Voith’s new OnQuality fiber orientation measurement and control

- Precise and continuous measurement of the fiber orientation profile

- Fully integrated QCS control of fiber orientation

- High savings due to the avoidance of B quality

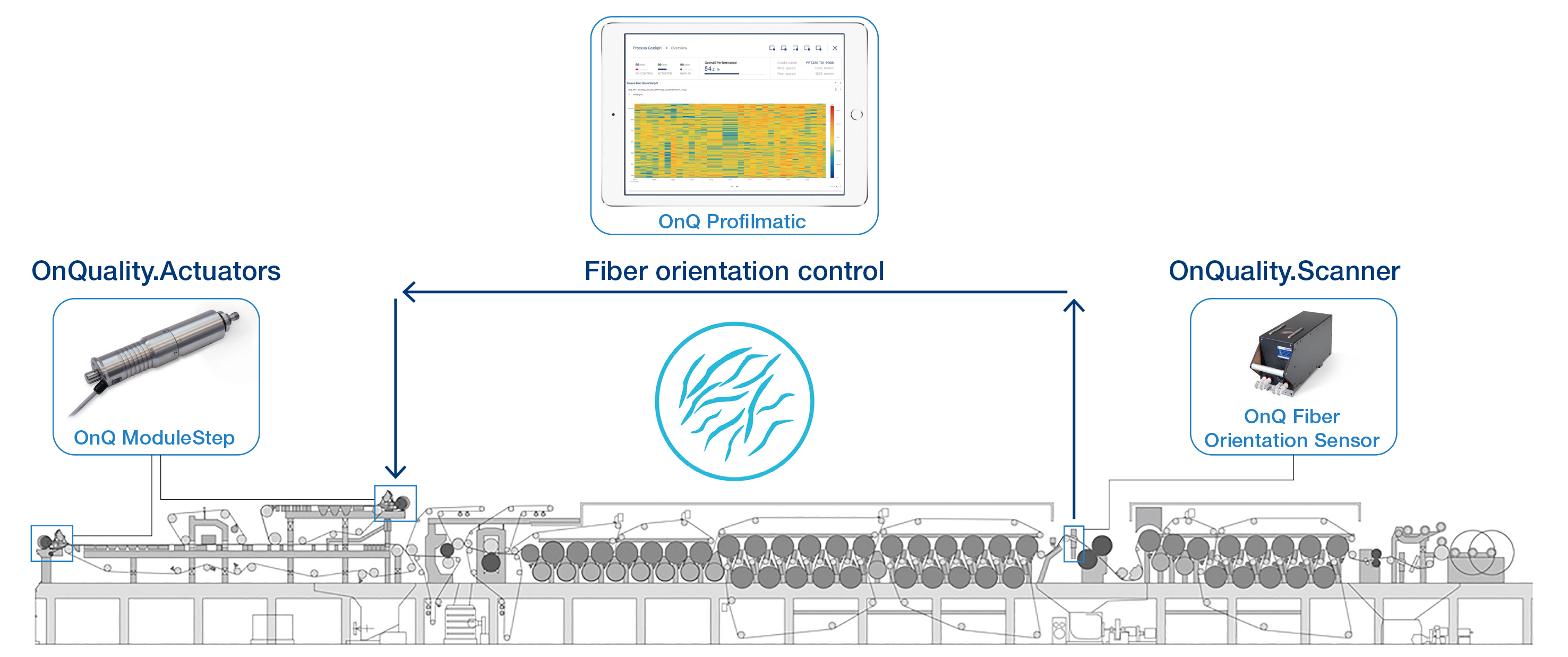

The OnQ Fiber Orientation Sensor continuously measures fiber orientation in real time. The new automation system also uses the OnQ Profilmatic CD control system and the OnQ ModuleStep and OnQ ModuleJet actuators.

HEIDENHEIM. With the newly launched fiber orientation measurement and control of Voith's OnQuality product family, paper manufacturers can reliably control the fiber orientation angle. The new solution consists of the OnQ Fiber Orientation Sensor, which continuously measures fiber orientation in real time; the OnQ Profilmatic fiber orientation control system; and the OnQ ModuleStep and OnQ ModuleJet actuators.

Naomi Voith

Global Communication Manager

t +49 7321 37-2209

Due to the precise control possibilities, major international packaging paper producers already rely on the application to ensure their product quality. After a short rebuild and commissioning phase, the investment pays for itself in most cases in less than a year. The integration of the quality control system is applicable for existing plants worldwide and independent of the manufacturer with little effort.

Functional principle of the new automation solution

The OnQ Fiber Orientation Sensor uses high-resolution macro photography, digital image processing and nanosecond flash illumination to distinguish the individual fibers and their orientation in the moving paper web. Surface measurement is possible on both one and two sides. The OnQ Profilmatic CD control system derives suitable set points of the OnQ ModuleStep actuators from the measured fiber orientation angles, which enable zonal, mechanical profiling of the headbox slice lip using stepper motors. In combination with the OnQ ModuleJet actuators, the dilution water can also be controlled, thus avoiding undesirable side effects on the basis weight.

OnQuality 4.0

Voith's OnQuality 4.0 is an intelligent and integrated concept that enables manufacturers to gain control over production processes and product quality. A broad portfolio of scanners and sensors ensures reliable and continuous measurement of various quality parameters. The intuitive apps of the cloud platform OnCumulus provide a wide range of analysis, reporting and visualization functions that are available at any time via different end devices and optimally complement the fiber orientation solution. In addition, the paper technology experts at Voith's OnPerformance.Lab provide support to further increase the efficiency and productivity of the plants with the help of remote consulting and optimization. For more information, visit voith.com/OnQuality.

Automation is a focus of Voith's new "PAPER IS ON" campaign. The campaign highlights the focus topics of full-line supplier, efficiency, sustainability, cloud solutions and innovation, which impact the digital product portfolio. Learn more at voith.com/PaperIsOn.

About the company

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

read more

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and supports customers in significantly reducing their carbon footprint. With its comprehensive automation products and leading digitization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art, digital technologies to increase the availability and efficiency of their systems in all areas of the production process.