High-tech carbon fiber composite manufacturing and development

With Voith HySTech, you get

because our products are more than lightweight.

Are you looking for a customized carbon fiber-reinforced polymer (CFRP) solution for automotive parts or hydrogen storage? Then you have come to the right place!

To increase the quality, safety and operating efficiency of your applications, we design and manufacture tailored and industry-leading CFRP products.

Composite materials have many special properties that deliver new opportunities.

What are composites?

Composite materials, such as carbon fiber reinforced polymers (CFRP), combine two or more materials with different properties to create a new material for efficient use in many applications. CFRP uses carbon fiber and a resin binder. This combination results in a lightweight and very robust material suitable for high-performance applications.

CFRP enables weight reduction, and performance improvements in products for automotive, transportation, and other industries. The tailored properties allow engineers to design innovative structures and push performance boundaries i.e., more speed, higher functionality, better handling and tougher parts.

Composites products

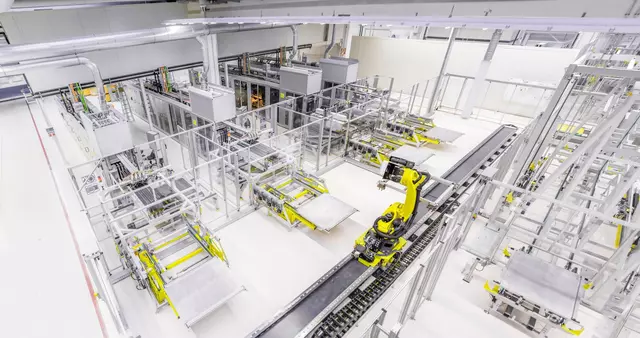

Our fully automated, digitally integrated production facility ensures repeatably high-quality parts with every production run. By applying cutting-edge Composites 4.0 principles, we guarantee flawless CFRP parts - regardless of batch size and with shorter lead times. Our primary focus is on maximizing cost-performance efficiency and minimizing total cost of ownership.

Carbon4Tank is a Type IV high-pressure H₂ tank manufactured using TowPreg filament winding technology.

Development and production of customized composite materials in a fully automated production environment.

Would you like to know more about the production of CFRP solutions? Then scroll on here:

How are carbon fiber products made?

Resin Transfer Molding (RTM)

RTM is commonly used for manufacturing custom carbon fiber composite parts, for example, car bonnets or rotor blades of ships. It allows flexibility in producing large, complex shapes with precision. A CFRP preform of the final part, which is called “stack” is formed in a heated steel mold to gain its precise 3D shape. Afterwards, liquid resin is injected into the closed mold, flowing through the preform to thoroughly soak the fibers under pressure. The heat from the mold cures the resin-soaked preform into a hardened composite part with an excellent surface finish right out of the mold.

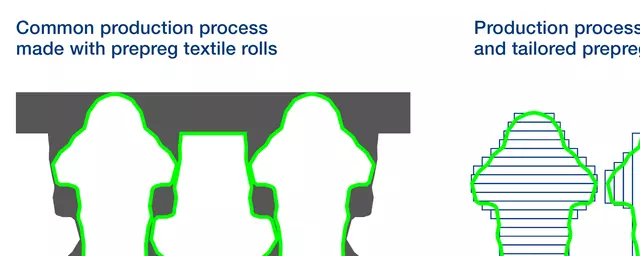

Prepreg Pressing

Prepreg pressing is an efficient way of producing CFRP products in series like automotive underbody structures or B pillar. The stack (the basic shape of the component in 2D) is created with pre-impregnated fibers. The final hardened 3D contour is formed by heat and pressure in a mold that models the negative shape of the component.

Filament Winding

Filament winding is ideal for manufacturing cylindrical composite structures like pipes, compressed gas cylinders, or huge rolls e.g. for paper machines. The continuous carbon fibers are impregnated in a resin bath, which is why this process is also called “wet winding”. Then the impregnated fibers are wrapped immediately around a rotating mandrel that forms the internal shape. The winding pattern can be optimized for the load characteristics of the cylinder.

TowPreg Winding

TowPreg winding is another method to produce composite rolls with higher safety and quality standards. The difference to filament winding is that the fibers are not exposed to a resin bath. The fibers are given an optimized pre-impregnation, which leads to lower resin consumption. This results in the so-called TowPreg material. Cylindrical shapes, such as hydrogen tanks, are produced by using the TowPreg material in a winding machine. Due to the optimized stickiness and viscosity of the material, TowPreg winding is a particularly efficient method.

Liquid Infiltration

Liquid infiltration is used to produce big and complex composite parts in small quantities. Typical applications are larger yacht hulls, rotor blades, or vertical stabilizers of airplanes. In this process, dry textiles are vacuum infiltrated with low-viscosity resins in an open mold and vacuum bags. Afterward, the composite material is fully cured in the autoclave at heat and pressure.

There are several other methods for producing carbon fiber parts, such as 3D printing and injection molding. The optimal process depends on the specific requirements of the product being manufactured.

Voith’s innovative production processes

Voith has optimized the tape placement and filament winding process for carbon fiber parts. We refined these two processes to meet customer requirements and realize maximum performance of their application. Our engineering enhancements target both the quality standards as well as the production efficiency and benefits of our customers.

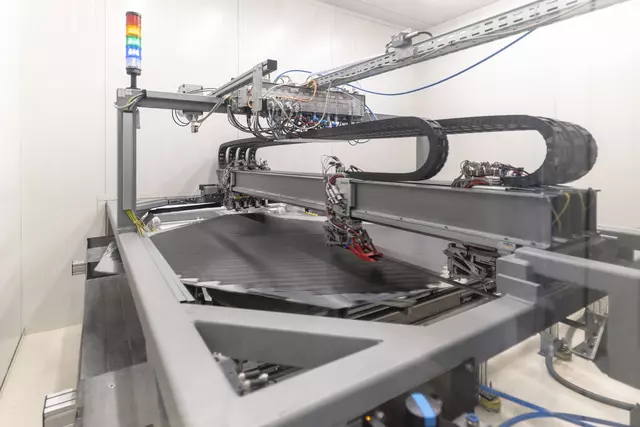

Voith Roving Applicator (VRA)

Developing a fully automated and digitized multi-tape placement system

The fixation line before the VRA binds dry carbon fiber into 50mm wide tapes using heat and binding powder. These unidirectional carbon fiber tapes are fed into the VRA placement head. This places up to four tapes in parallel down to a tailored preform. The computer-controlled and autonomous process uses a 360° rotating table and four independent grippers capable of simultaneous multi-axis movement. This enables precise, rapid layup of near-net shape preforms.

Advanced software control allows the VRA to achieve excellent repeatability and material utilization efficiency across all lot sizes. After preforming, the parts undergo resin injection and curing via RTM molding. Final machining like milling and drilling prepares the finished part.

By digitizing the entire process, the VRA maximizes output speed and part quality consistency. Real-time monitoring provides process data to enable continuous refinements. This pioneering automation brings carbon fiber composite production into the future.

Voith Roving Applicator (VRA) NextGen

Upgrading for faster production flow

TowPreg Filament Winding

The most efficient process for producing high capacity and safety CFRP tanks

Our specialized TowPreg winding technology improves this process for manufacturing high-pressure CFRP tanks. From the efficient, economical use of fibers and resin to the ingenious winding patterns/layers and faster and precise winding. As a result, our tanks achieve an outstanding high H₂ capacity with optimized tank geometry and lower weight. This saves space and allows you to store more hydrogen or achieve a greater range with the H₂ vehicle on land and water.

Composites 4.0

Composites manufacturing of the future

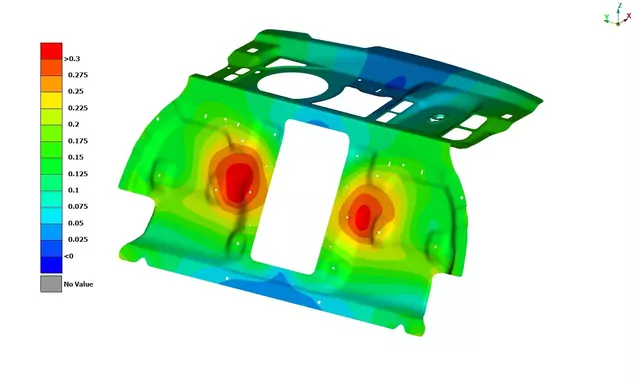

Research and development

We continue to enhance our expertise in numerous development projects – on our own and with research and industry partners.

R&D and production

R&D and production center

- Design with CATIA and Inventor

- FE simulations using ANSYS and Abaqus

- Material analyses using DMTA, TGA, CT and microscopy

- ThinPly

- In house burst tests at our own test station

Engineering

Engineering

Are you looking for new CFRP solutions? Our experts combine experience and knowledge for a variety of complex material requirements. Talk to our team today to find the ideal solution for your project.

Resources

News

For hydrogen tanks to be released on the road, the law defines that they must be certified beforehand. In Europe, type approval on H₂ tank systems is governed by the regulation UNECE R 134. Now, for the first time, a Type IV 700 bar and 350 litre hydrogen capacity tank has been approved for road use under the guidelines of the United Nations Economic Commission for Europe.

Read the full release

We're developing recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials. Our focus lies on advancing two distinct recycling approaches in particular: one tailored for recycling of manufacturing scraps, and the other designed for end-of-life (EOL) components like hydrogen tanks. Read more in CompositesWorld's article.

Voith Composites, the Composites 4.0 industry leader and production center of carbon fiber-reinforced composite solutions (CFRP) in the Voith Group, has won the JEC Composites Innovation Award 2022 for the development of the Voith Inline Thruster CFRP rotor blades using Carbon4Stack and Carbon4Tool.

read moreContent

BMW M is an innovator in the automotive industry. While CFRP techniques are slowly being adopted by some auto manufacturers, the BMW Group and BMW M are already realizing the potential of having successfully integrated CFRP parts.

download the case study

HORYZN is a student initiative focused on real-world use cases for UAVs (Unmanned Aerial Vehicles). The team from TU Munich works collaboratively on the design, development, and implementation of UAVs for social good. Voith Composites was approached to support HORZYN’s latest project, an eVTOL (electric vertical take-off and landing) UAV for medical emergencies, providing its CFRP tooling solution – Carbon4Tool - which has helped the project achieve early success.

Read the case study

Composites 4.0 is part of what we know as Industry 4.0 or more commonly, digital transformation. It enables automation and data exchange in manufacturing technologies within the composites industry. It’s about developing technology to make the best of composite manufacturing - building smart factories and processes that are optimized to reduce waste and cost while increasing the quality of composite parts.

Download the white paper

DUQUEINE Group - a world-class manufacturer of composite parts in France - joined forces with Voith Composites to test Carbon4Tool - Voith’s innovative new carbon-fiber-reinforced polymers (CFRP) prepreg material for tooling applications.