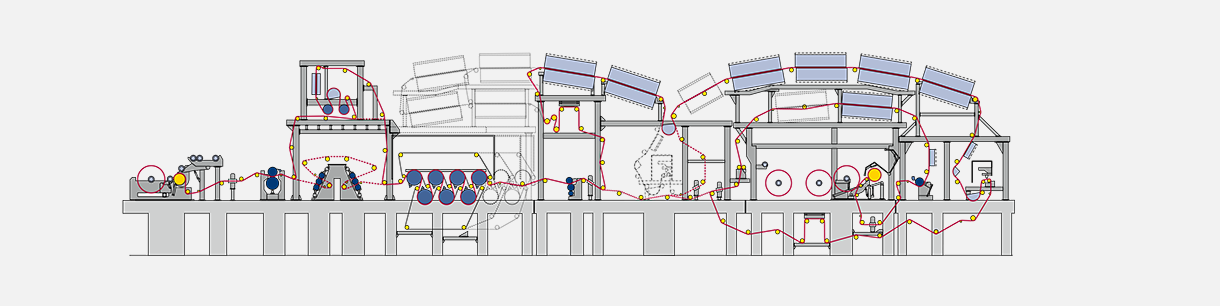

Production line 8 in Kehl: One of the most powerful specialty paper machines in the world

With an investment amount of 300 million euros, the construction of production line 8, comprising paper machine 8 and coating machine 8, was the biggest single investment in the history of Koehler. Designed for around 100,000 tons per year, production line 8 produces a wide range of specialty paper and paper with functional surfaces for flexible packaging. Production line 8 began operating in 2019.

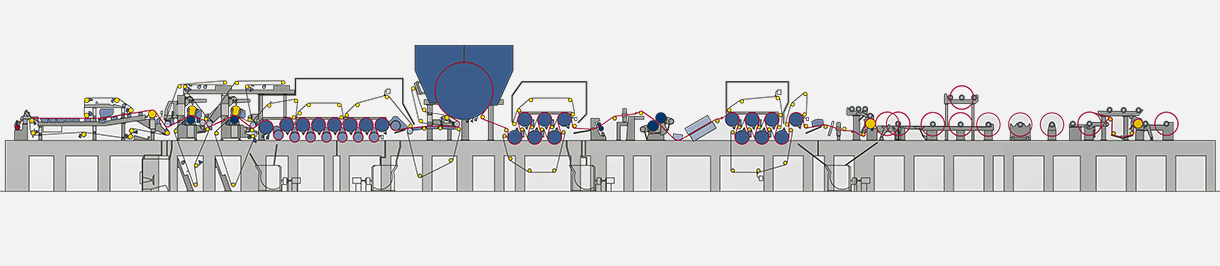

The heart of paper machine 8 is the Yankee cylinder with a diameter of 730 cm, which gives the paper its unique smoothness. PM 8 runs at 1,400 m/min and has a working width of 426 cm. Coating machine 8 is used to give the paper a variety of functional coatings, with the distinguishing feature being that up to three coatings can be applied in one pass.

Together, Koehler and Voith are stepping up to change the world of packaging – and make it more sustainable

According to Greenpeace, there are 150 million tons of plastic waste floating in the oceans, a significant proportion of which is packaging. The packaging industry is therefore under huge pressure to change. While the plastic industry reflects on its problems, Koehler Paper has identified the potential here. A forward-looking solution is paper packaging. Produced from sustainable materials, recyclable multiple times over, and easily compostable, it is a convincing alternative to plastic packaging. Koehler NexPlus® paper from this range aims to replace plastics in many primary and secondary packaging applications.

Sustainability at Koehler is not limited to manufacturing practices, but influences all aspects of thinking and behavior. We handle resources like water responsibly. The pulp for the production of fresh fiber paper comes from certifiable, sustainable forestry and controlled sources. Thanks to continuous internal improvement processes, all Koehler employees contribute toward saving resources, streamlining processes, and optimizing workflows. The company has therefore become the industry benchmark in many areas.

Based on the tradition of a family-run company and full-line provider, Voith too is committed to ensuring that its economic activity is environmentally-aware, fair, and successful in the long term. The company aims to make a measurable and visible contribution to the sustainable development of business activities, the company, and the environment, and in doing so to adopt a leading role as a trailblazer. The technology leader is addressing global mega-trends such as decarbonization, digitalization, and the circular economy through resource-saving paper production.

A new business area emerges and begins with a major investment

Koehler invested 300 million euros in the new paper and coating machine. Barely any other family-run company of Koehler’s size can cover that kind of investment. Koehler itself is only able to do so thanks to its sustainable management in the past.

The decision to invest in a new business area was a strategic one. Koehler has centuries of expertise in papermaking and is now transferring this knowledge to a new field – a field that is rapidly gaining importance in times of climate change and sustainability commitments.

Once the decision to invest in a new production line for flexible packaging paper had been made, we had to choose a suitable partner. Voith, as a full-line provider for the paper industry, was our first choice. For many years now, Voith has been firmly committed to the development of sustainable products and processes. With its innovations, the company has taken on the role of technology leader.

Successful team effort - from joint development work and record construction time to final commissioning

When the decision was taken to construct the new production line 8, extensive research and development work got underway at Koehler. In the in-house laboratory, around 200 material screenings were implemented under high pressure and, with a lot of inventive talent, new target applications were defined and, ultimately, product concepts for new markets were established. The challenge was to find materials that not only met regulatory requirements, but also continuously retained the desired application properties when further processed. Strength and durability as well as aroma protection and content protection are particularly important.

While the paper machine was being constructed, the team in the adjacent hall was assembling the coating machine, which lends the production line its unique flexibility.

Once the research and development work as well as the design were completed, production line 8 at the Kehl site was installed within just two and a half years. The high level of trust between Koehler and Voith played an important role during the construction phase. The combination of technical expertise from both companies was essential to the successful implementation of the project with its ambitious time scale.

Production line 8 was commissioned by teams consisting of production, engineering, and technology employees from Koehler and Voith. The individual segments of the paper and coating machines were tested chronologically, initially without paper, but with water instead. From the ‘stock on wire’ date, the team started to add raw paper mixture from the pulper to the paper machine. In time frames of up to several days, the individual machine segments were thoroughly tested one after the other and challenging machine sections, such as the press section and drying section, were successfully commissioned.

Paper machine 4.0

To maintain the mill, Koehler uses the OnCare.Health digital monitoring, analysis, and diagnostic system from Voith. The system combines Voith’s expert knowledge in technology and maintenance with Koehler’s many years of operational expertise. This means it is possible to integrate preventive maintenance, which is customized to the mill in Kehl. As a result, PM 8 is not only extremely reliable – it’s also fully controllable. The level of digitalization is very high compared to other paper machines, and provides a large amount of measurement data.

OnCare.Health immediately triggers an alarm in the event of unexpected measurements. Since all measurement data is saved for the long-term, it is also possible to identify trends and future developments. Thanks to a variety of interfaces, simple data exchange with external systems is also possible. OnCare.Asset from Voith guarantees a transparent maintenance process in the production line and inventory management throughout the entire paper factory. To stabilize and optimize the product quality and the entire production process of paper machine 8, Koehler also commissioned Voith to integrate the Quality Control System (QCS) OnQuality including scanners and sensors.

A technical masterpiece

Comprising BlueLine stock preparation, a wet end process, XcelLine paper machine, offline coating machine, and VariPlus roll cutter from Voith, production line 8 is one of the most powerful specialty paper machines in the world. Around 4,000 measuring instruments and just as many moving cylinders, flaps, and control elements interact on a highly automated basis to produce the specialty paper. In keeping with the Koehler motto ‘optimization down to the finest detail,’ the paper and coating machines are continuously fine-tuned to achieve the maximum.

Installation of the 150 m long paper machine with a wire width of 5,000 mm required 4,000 tons of reinforced concrete in the carcass, 28,000 m3 of concrete, 120,000 limestones, 1,250 km of cables, as well as 62.6 km of pipelines.There were 750 employees in total working at the construction site. A particular technical highlight of production line 8 is the MG cylinder with a diameter of more than 7,300 millimeters. It is the world’s largest of its kind. During production, this ensures unrivaled paper smoothness, which is crucial in further processing. An innovative Nipcorect full-flex roll, as a press roll on the MG cylinder, enables ideal line load distribution over the whole width.

In addition to setting new benchmarks, the paper machine has also broken a number of records. The most significant is that it is the fastest MG paper machine in the world, with a continuous speed of 1,400 m/min over a period of 24 hours. Its premium quality is matched by its technological sophistication.