2019-05-09

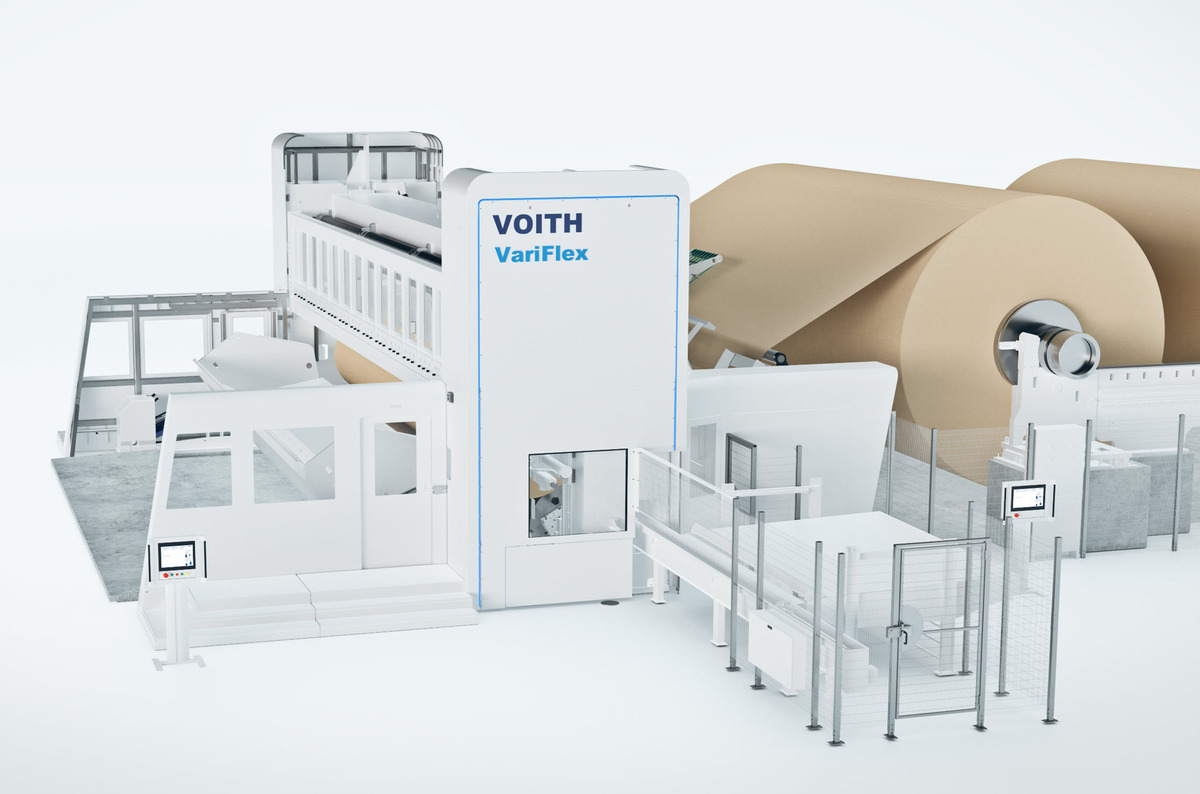

VariFlex Performance

High-capacity winding for demanding applications

- Newly developed high-performance winder for a working width of up to 10 meters

- Boosting set change time to 25 seconds

- Design speed of 3,000 meters per minute

VariFlex Performance was developed to meet the highest customer requirements.

HEIDENHEIM, Germany. Developed for the highest customer requirements and specially designed for maximum output: With VariFlex Performance, Voith sharpens its portfolio of two-drum winders.

VariFlex Performance is a new solution that has already been successfully launched on the market. With this leading-edge winder, Voith reinforces its position as a technology leader in the paper industry. It sets new performance standards in terms of high-capacity winding, thanks to a design speed of 3,000 meters per minute and a 25-second set change time. This results in a significant increase in both efficiency and productivity. VariFlex is designed for a working width of up to 10 meters.

“With VariFlex Performance, Voith has developed a new high-capacity winder that is designed from scratch to fulfill all customer demands. Consequently, this winder fully focuses on the best winding quality, reliability and maximum production,” says Christian Woelfel, Head of Application at Voith.

“VariFlex Performance is our foundation for implementing full digitalization and connectivity in the end section,” adds Daniel Juergens, Global Product Manager at Voith. “In combination with our upcoming developments in the end section, this winder is a central element to bring key features – such as predictive winding, fully automatic process communication and highest winder throughput – to the next level.”

Naomi Voith

Global Communication Manager

t +49 7321 37-2209

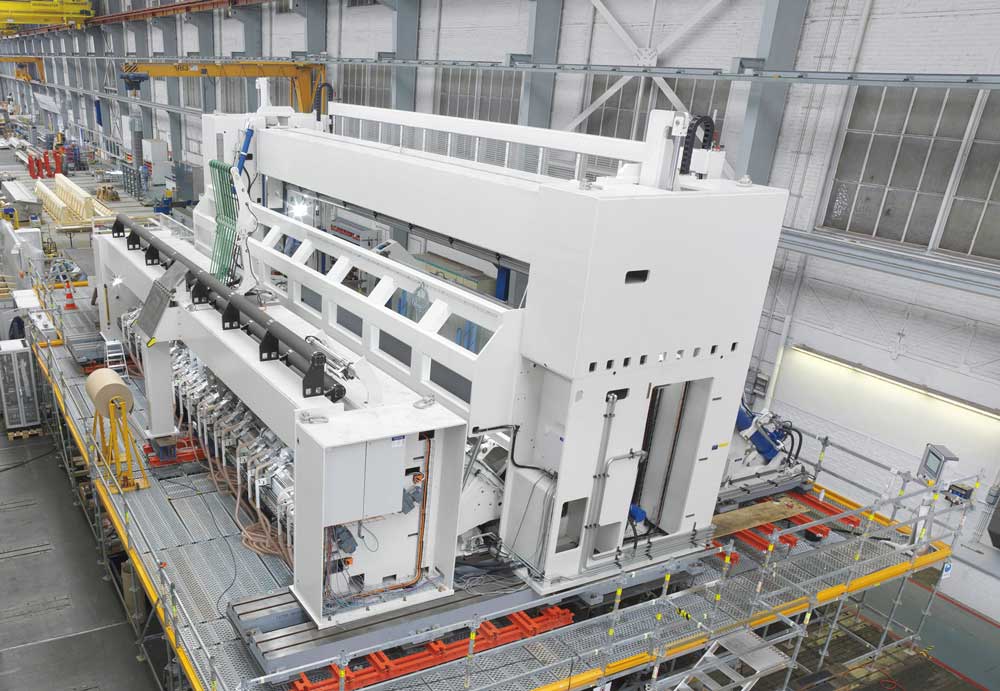

State-of-the-art technology

The unique Gecko OneStep system ensures reliable start and end gluing. Further boosting of the winding performance is achieved with SmoothRun technology. This active drum dampening system significantly reduces paper induced vibrations, leading to an increased capacity as well as brilliant winding results.

Innovative and user-friendly automation system

Live condition monitoring and a clear system analysis are features of the automation system. In addition, the system provides an easy data exchange to the mill system and enables the integration of automatic jumbo roll identification.

Short assembly and start-up time

For more information about VariFlex Performance, visit the Voith website:

www.voith.com/variflex-performance

About the company

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

More about the Voith Group

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and supports customers in significantly reducing their carbon footprint. With its comprehensive automation products and leading digitization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art, digital technologies to increase the availability and efficiency of their systems in all areas of the production process.