Equipment Services

Focus on equipment

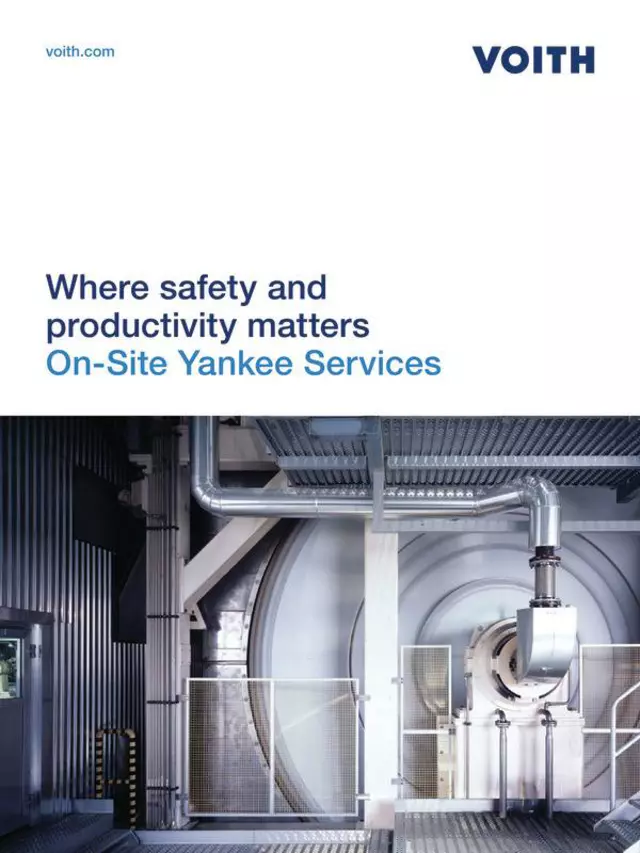

Voith works to ensure optimal performance and safe operation of process line equipment, systems and machine sections.

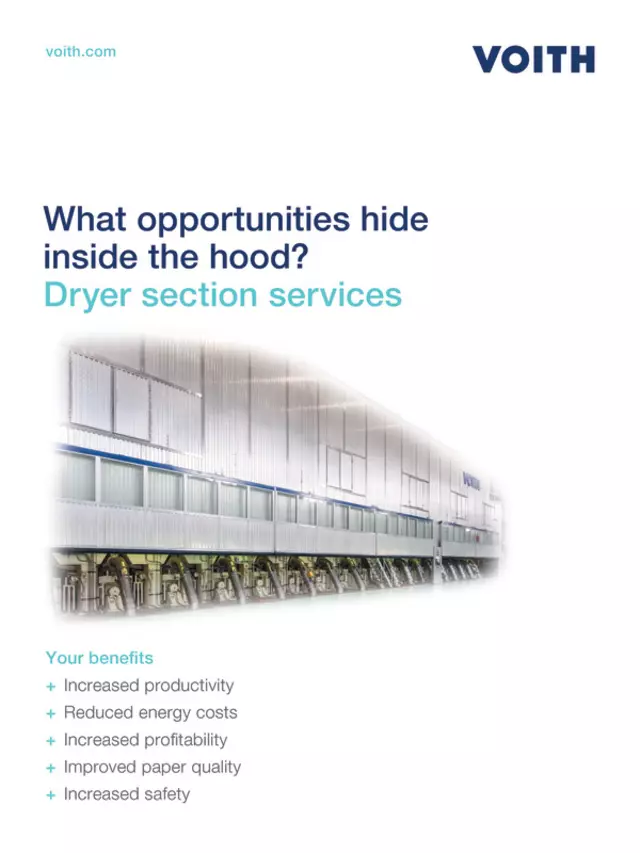

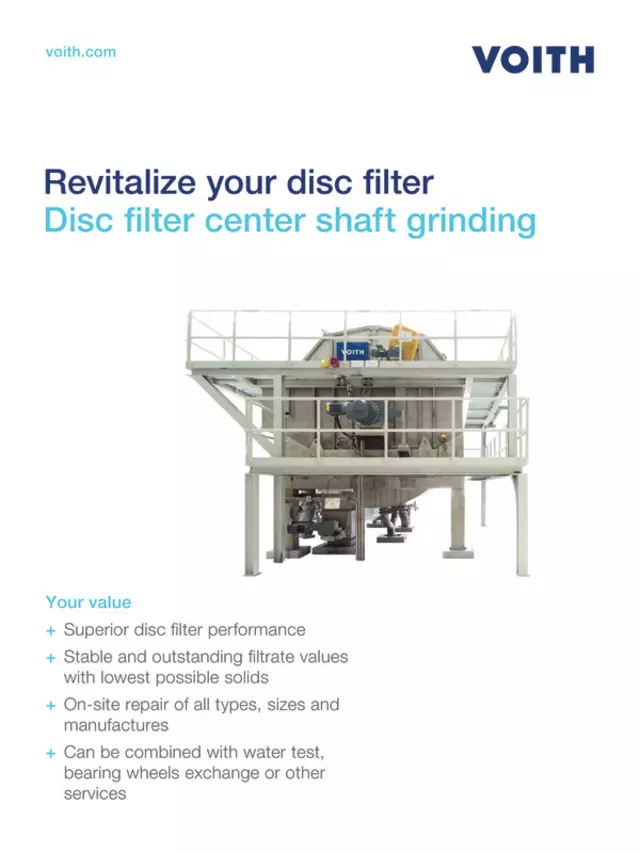

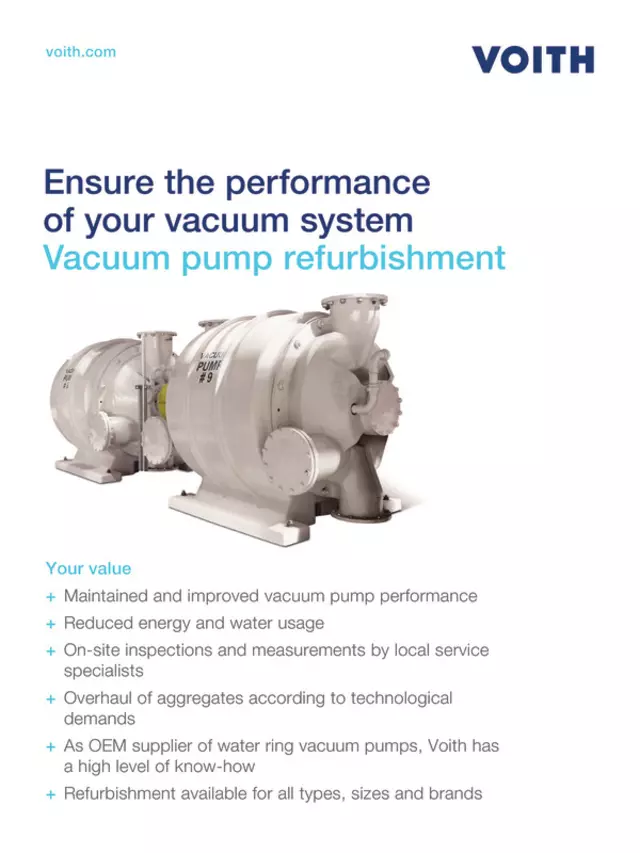

From initial installation to phase-out and replacement, papermakers can count on Voith for installation, commissioning, maintenance, repair, refurbishing and consumables required to optimize equipment availability. While our Equipment Services offering is designed primarily around maintenance activities, we also address the needs of paper production – particularly in the area of performance improvements and problem-solving measures. Learn more on our Process Services page.

Maintenance

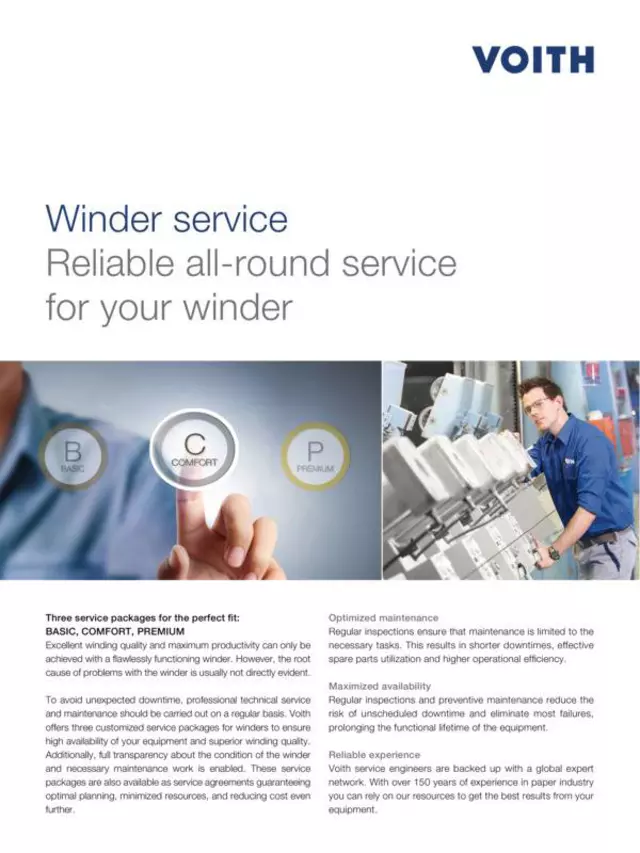

High quality maintenance services and efficient maintenance processes are a basic requirement to achieve maximized productivity and profitability.

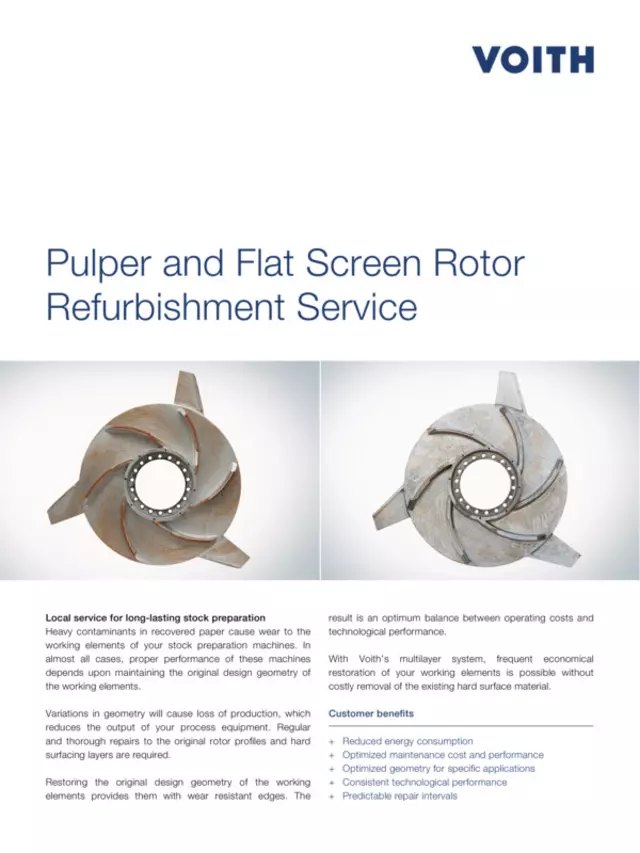

Regular maintenance by Voith minimizes failures and reduces the risk of equipment damage and personnel injuries. We offer comprehensive preventative, reactive and predictive maintenance and assist our customers to develop efficient maintenance processes. Our service solutions range from inspection, repair, and spare parts replacement to shutdown management and refurbishment of equipment. All those services can be performed on-site at the customers plant or off-site at a Voith workshop.

- Inspection

- Preventive maintenance

- Corrective maintenance

- Equipment improvement

- Repair & refurbishment

Installation and commissioning

With Voith’s track record of delivering some of the world’s most technologically advanced production lines, our customers can confidently place their trust in us for all commissioning activities – from installation to startup.

Our scope of delivery ranges from small machine components to complete production lines. With each project, we take full responsibility of the process, overseeing planning and scheduling, as well as every detail of commissioning and installation. We ensure reliable startup of your new equipment to achieve fast and sustainable performance, thereby accelerating your ROI.

- Installation

- Commissioning

Materials

With Voith original parts, our customers achieve a balanced cost-benefit ratio with top performance at the same time. Simple management and efficient ordering processes support your daily work.

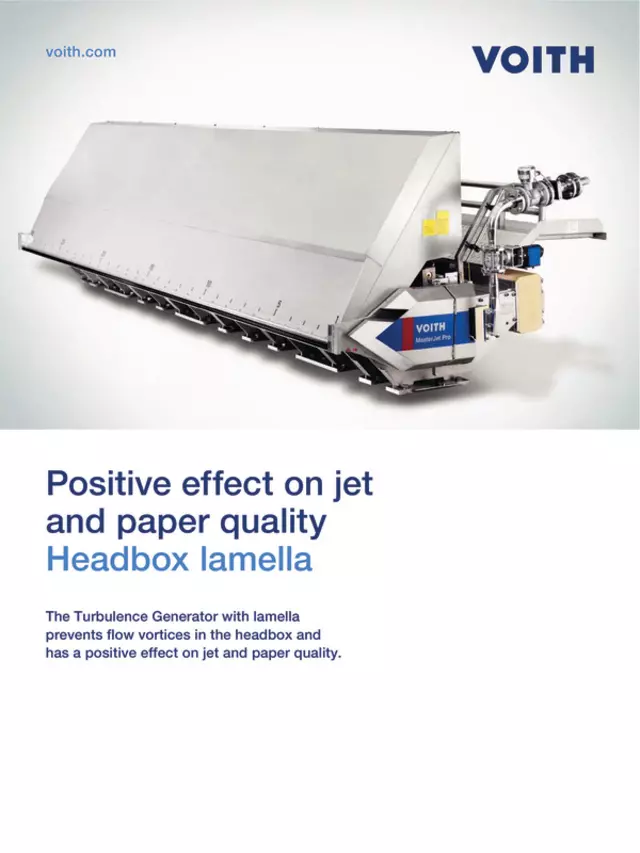

Our engineers develop leading fabrics and felts, roll covers, doctor blades, stock preparation materials and more – all designed to operate at peak performance for the highest cost efficiency. Our products are supported by a specialized service force to help you select the best technologies for your applications. This all adds up to the best performance and lowest total-cost-of-ownership for your production consumables. Use the Voith Paper Webshop for easy and fast ordering of all spare and wear parts.

- Spare parts

- Wear parts & consumables

Downloads

What can we do for you?

Find your local Voith contact person or send us a message with your request

Product world

From the fiber to the finished paper we offer a diverse product portfolio for any application. Here you can find the right products for your plant. Let our product innovations inspire you.

Further information

Experience the Servolution

What is your concern?

Our service offering