Our Hydrodamp vibration damper series for tractors, construction machinery, buses, trucks and rail vehicles

Modern, high-torque and fuel-optimized engines place significantly more strain on drive trains than before. Our Hydrodamp vibration damper series protects the drive train of tractors, construction machinery, buses, trucks or rail vehicles from overload and increases the service life of the individual components.

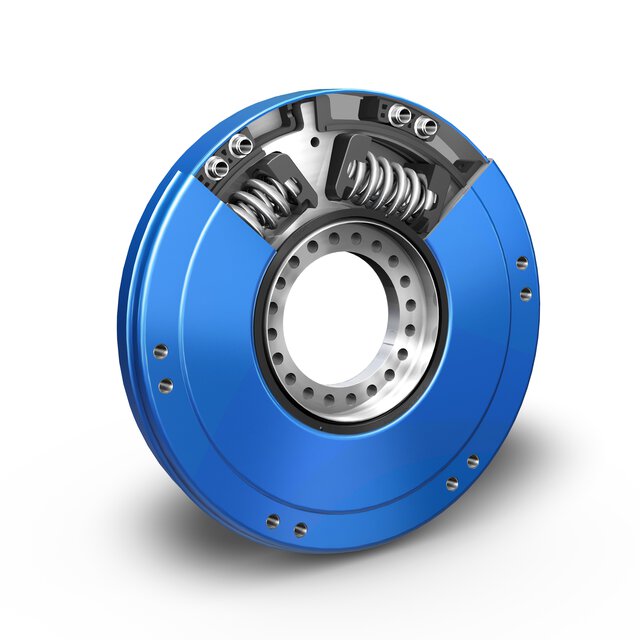

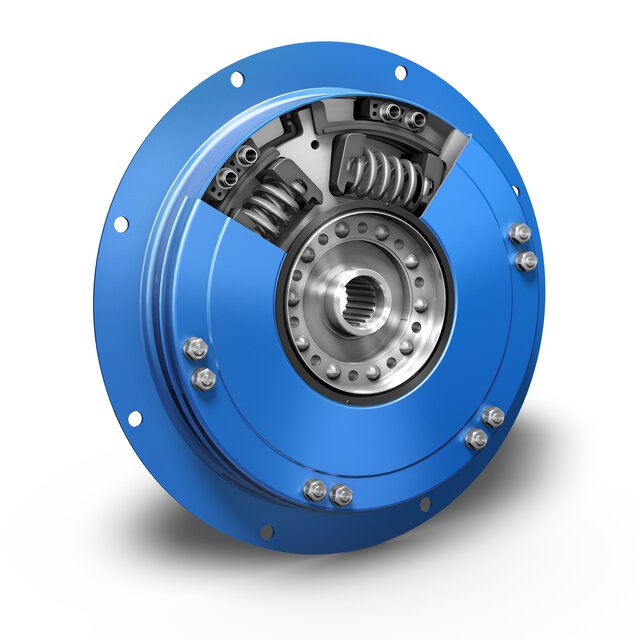

The Hydrodamp is a highly elastic vibration damper with a spring-mass system and a separately arranged hydraulic damping system. The low spring stiffness in conjunction with favorable mass ratios relocates critical resonances to areas below the Operating speeds. Regardless of this, the hydraulic functional principle for vibration damping and isolation is designed for the operating speed ranges.

The vibration damper is available in three vehicle and application-specific series for engine torques of up to 3,700 Nm. Each can be customized in terms of damping and suspension characteristics. Equipped in this way, the flexible Voith Hydrodamp proves itself in tractors, construction machinery, buses, trucks and rail vehicles from leading manufacturers.

All benefits at a glance

- Protection of the drive train against overloads

- Extending the lifespan of all components

- Reduction of vibrations and noise

- Increase in comfort

- Improvement of economic efficiency

|

|

The Hydrodamp ranges have been developed based on a modular principle. The connection to the customer’s own individual drivetrain is achieved by means of solution variants for primary and secondary side, such as SAE centering flanges, hubs and cardan shaft connections. Within the series, by adjusting the characteristic curve and damping characteristics, the Hydrodamp can be precisely adapted to the drivetrain’s requirements.

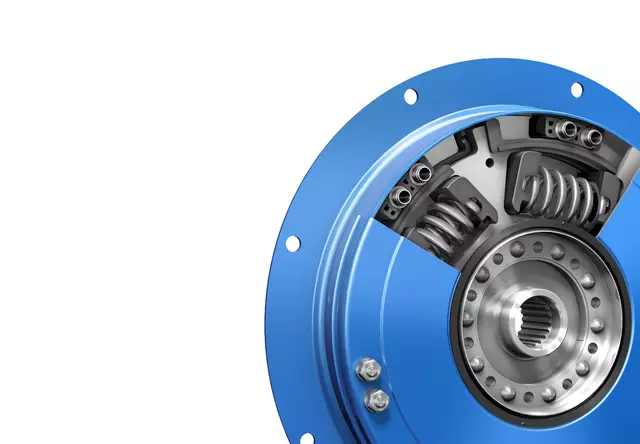

The new Hydrodamp 365 AG – especially developed for agricultural tractors

Brings peace to the driveline – also for heavy agricultural tractors.

The Hydrodamp agricultural range has been specifically developed for the drivetrains of state-of-the-art, powerful agricultural tractors. The higher torque capacity caters for the increased requirements of modern engines. Optimal reduction of torsional vibration maximizes vehicle operation efficiency.

- Increases the service life and operational availability of your tractor.

- Reduces fuel consumption.

- Enables the use of high-power engines (downsizing).

- Increases driving comfort due to reduced vibrations.

Do you wanna learn more about the Hydrodamp 365 AG?

Our Service - Part of Your Business

- Everything from a single source: development, design, production – and service!

- Decades of product experience as an original equipment manufacturer and service provider

- Fast and smooth cooperation and best service thanks to a worldwide network of service locations

- Long-term partnership and planning security are guaranteed due to longstanding corporate stability