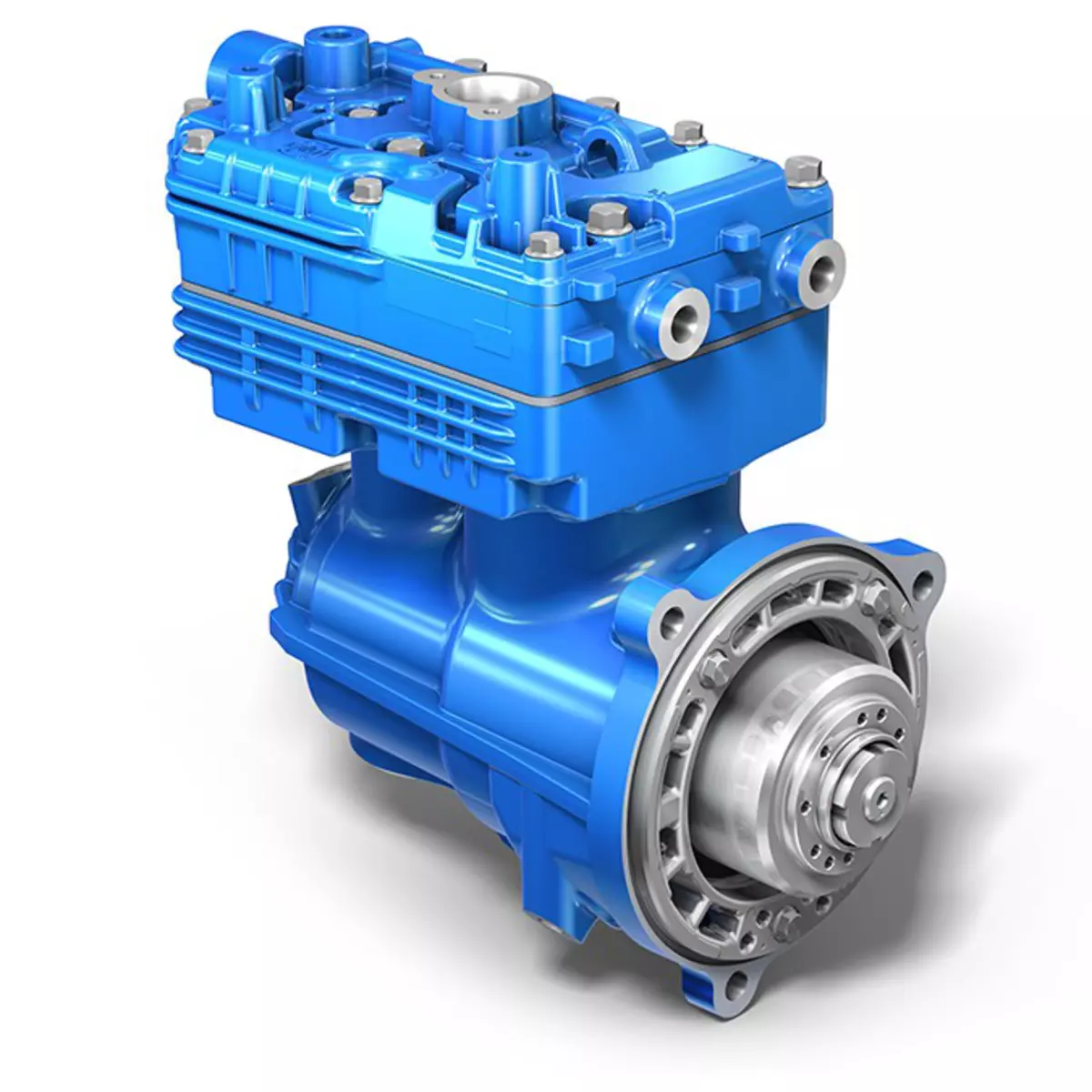

More power, less energy consumption – Voith air compressors with SLS, TwinSave technology or integrated clutch

With leading technology, Voith air compressors use two-stage compression with an intercooling system. In comparison to single-stage air compressors, this allows for substantially higher output with a significantly reduced energy consumption in delivery mode. Even more, Voith air compressors with innovative technologies also provide maximum efficiency in non-delivery mode.

Voith air compressors make an important contribution to the cost-effectiveness and sustainability of internal combustion engines. The two-stage compression with an intercooling system plays a decisive role here. This significantly lowers the power consumption in delivery mode. In addition, the reduced compression temperature allows for considerably longer operating times, which increases the maximum delivery capacity with the same cylinder displacement. The lower temperatures also ensure that the oil does not "crack." Fewer damaging byproducts protect the compressor, engine, compressed air system and the environment at the same time. Furthermore, smart technologies such as SLS, TwinSave or an integrated clutch effectively lower energy consumption in non-delivery mode. Another contribution to more sustainability is the low weight of the systems thanks to the light-weight aluminum construction in large-volume production. Voith air compressors thus guarantee maximum energy efficiency, low-emission operation, low weight and long maintenance intervals.

Energy-efficient on all roads Voith air compressors

Low energy consumption in non-delivery mode thanks to innovative idling systems

Longer duty cycles (up to 85 %) due to innovative cooling concept

Significant weight reduction due to die-cast aluminum leads to an increased load capacity

Lower fuel consumption

of up to 1 L/100 km

Energy recovery in braking and coasting mode

Better air quality, higher availability of the air system as a result

Discover the LP560 in detail

Our Service - Part of Your Business

- Everything from a single source: development, design, production – and service!

- Decades of product experience as an original equipment manufacturer and service provider

- Fast and smooth cooperation and best service thanks to a worldwide network of service locations

- Long-term partnership and planning security are guaranteed due to longstanding corporate stability