Great people with a passion for technology

At Voith, we work on global challenges. We strive to make the energy that powers homes greener. We make working out at sea safer. Our ideas turn buses, trains and transport that move people and goods cleaner and more reliable. And, we strive to make the world of paper around us – from banknotes in India, tissues in China, to the cups for your morning coffee to go – more sustainable. Competent, motivated and involved – it’s the people that drive our innovation and global competitiveness.

Our fields of activity

Gain exciting insights into the various work environments at Voith and get to know our employees.

Engineering

Our engineers play a key role in the development of innovative technologies and sustainable solutions. With increasing digitalization and automation, the requirements and opportunities in engineering will also continue to evolve, which requires continuous learning and adaptability.

The field of engineering offers exciting and varied career paths with the opportunity to make a significant contribution to society and technological development.

The field of engineering offers exciting and varied career paths with the opportunity to make a significant contribution to society and technological development.

Information Technology (IT)

In this field of work, you will work at the interface between state-of-the-art technology and the diverse requirements of our business areas to develop customized IT solutions that promote efficiency, security and innovation. Whether in the area of IT infrastructure, software development, cybersecurity or data management, at Voith you will have the opportunity to contribute your expertise and make a significant contribution to the digital transformation.

Research & Development

Our research & development engineers are the driving force behind innovation and technological breakthroughs. You work to develop new products, technologies and processes that give our customers around the world a competitive edge. With your creativity, technical knowledge and ability to solve complex challenges, you will play a key role in ensuring that Voith continues to be recognized as a pioneer in the industry.

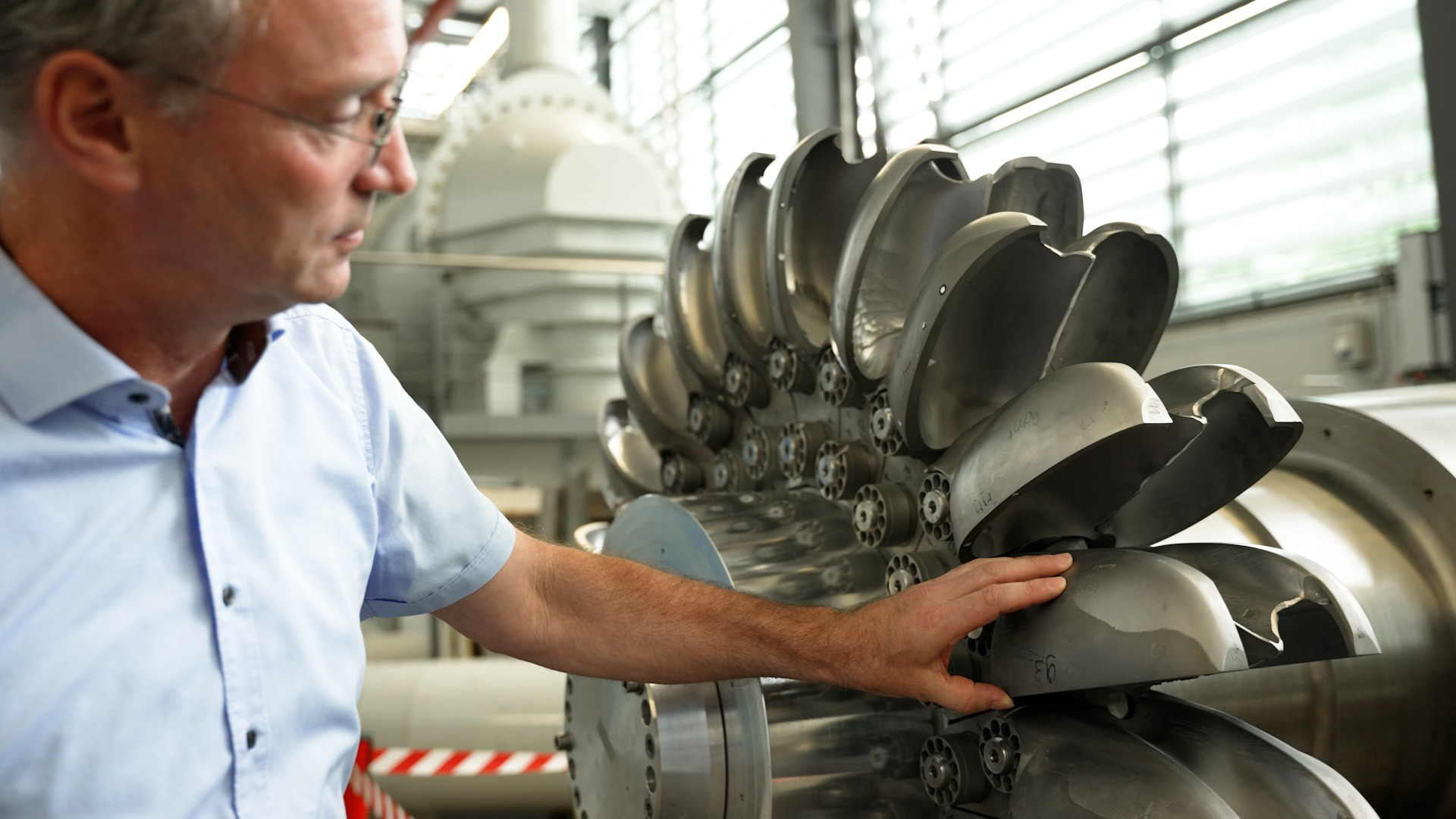

Operations & Production

In this area, you are essentially responsible for the smooth running and continuous optimization of our production processes. You will monitor production, implement advanced methods and technologies and ensure that our systems are operated efficiently and safely.

Your ability to master complex challenges and your passion for technical perfection make you an indispensable member of our team.

Your ability to master complex challenges and your passion for technical perfection make you an indispensable member of our team.

Field Service, Erection & Maintenance

At a time when technologies and services are becoming increasingly complex, Field Service plays an indispensable role in ensuring operational readiness and customer satisfaction. As a Field Service and Installation specialist, you are at the heart of technical support and on-site problem solving.

Your tasks will range from installing and maintaining sophisticated machines and systems to training customers and carrying out repairs. You can expect a varied working environment that requires technical know-how, manual dexterity and a high degree of flexibility.

Your tasks will range from installing and maintaining sophisticated machines and systems to training customers and carrying out repairs. You can expect a varied working environment that requires technical know-how, manual dexterity and a high degree of flexibility.

Sales & Services

In our Sales & Services team, you are the key to our success. You will work closely with our customers to develop customized solutions that meet their specific needs. With your consulting expertise and technical know-how, you will help our customers achieve their goals and increase their competitiveness.

Quality & Supply Chain Management

In Supply Chain and Quality Management you are the guarantor for the quality and reliability of our products and services as well as for the optimization of our procurement processes and supply chains. Your negotiation skills, strategic thinking and ability to build relationships are keys to ensuring that Voith achieves its operational goals and remains competitive.

With your analytical skills and in-depth understanding of quality processes, you will play a key role in ensuring that Voith products meet and even exceed our customers' expectations.

With your analytical skills and in-depth understanding of quality processes, you will play a key role in ensuring that Voith products meet and even exceed our customers' expectations.

Finance & Controlling

The broad field of Finance & Controlling offers you a crucial role in managing and monitoring our financial processes. You will be responsible for preparing financial reports, budget planning, cost controls and analyses that enable sound business decisions to be made. With your analytical thinking, understanding of figures and attention to detail, you will contribute to our success.

Group key functions

Project Management

You are the linchpin for the successful implementation of our projects. You plan, coordinate and manage projects from the conception phase to the final handover and ensure that schedules, budgets and quality standards are met. You help to ensure that our projects are completed on time and to the satisfaction of our customers.

Tax & Legal

In a world characterized by constantly growing legal requirements and complex tax regulations, tax and legal specialists are indispensable. As an expert in this field, you play a central role in ensuring compliance and developing strategies to optimize tax and legal structures.

Human Resources

In HR, you will support and promote the further development of our most valuable resource – our employees. You will oversee aspects ranging from recruitment and training to employee retention and development. You help ensure that our employees can develop to their full potential.

Our mission is to create a working environment that promotes innovation, commitment and growth.

Our mission is to create a working environment that promotes innovation, commitment and growth.

Further opportunities, tips & more

Learn more about your opportunities at Voith