Simple & reliable operation that is customized to your requirements

Offering incredible versatility, reliability, and simplicity combined with customization, our hydrodynamic torque converters for industrial applications are designed to the exact characteristics of the driven machine within your application.

These compact and robust torque converters have a long lifespan, even when operating in harsh environments, with the capability to modulate torque and speed up to 100 MW. Based on the fundamentals of hydrodynamic power transmission, these units are trusted and have been used in industrial applications since 1950.

All benefits at a glance

10,000

Highest proven reliability with over 10,000 installations

Precise torque

Precise torque and speed control for a wide power range

Easy start-up

Easy start-up and handling of high break away torques and inertia

Grid protection

An unloaded motor start ensures grid protection

Small footprint

Owing to a high power density

Long lifespan

Robust and durable design

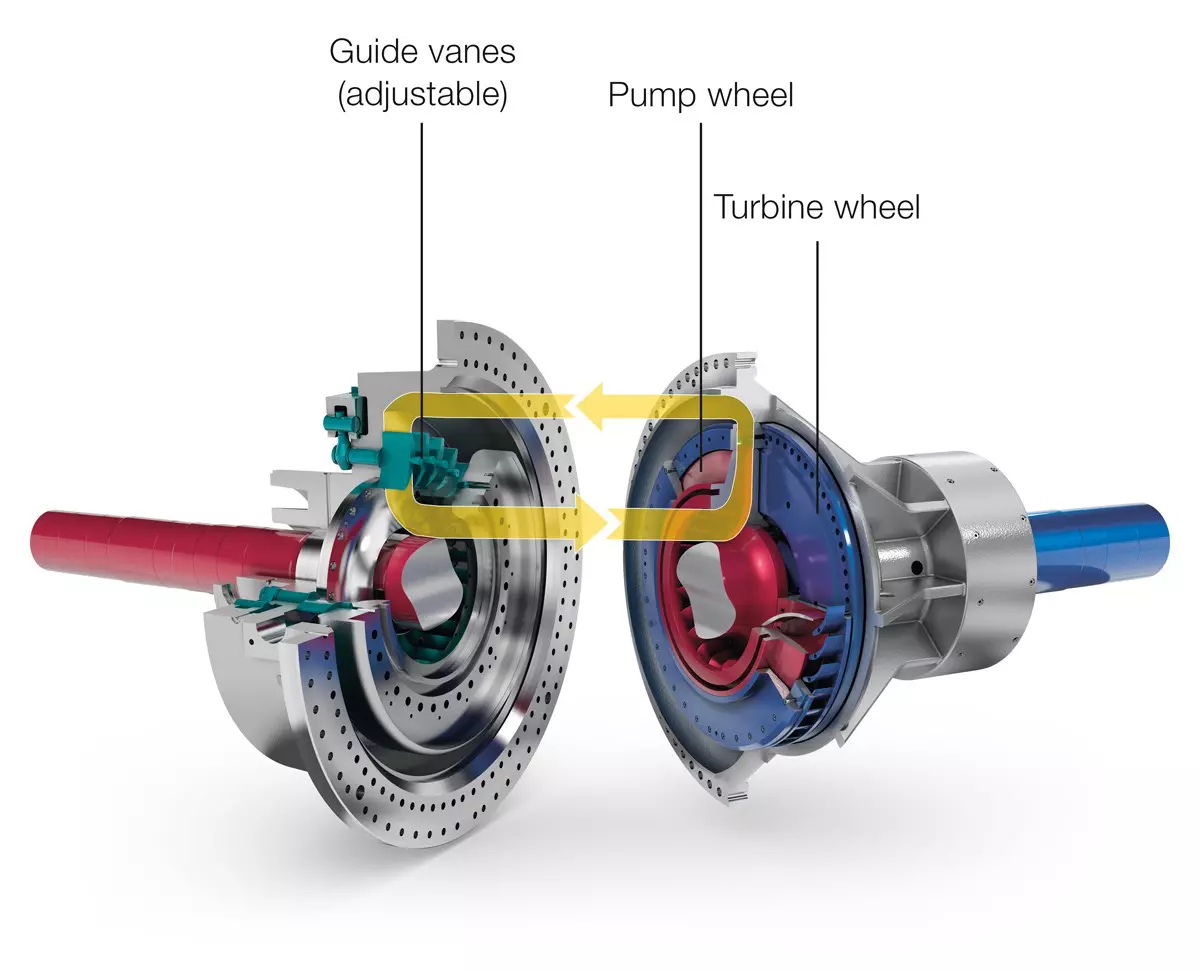

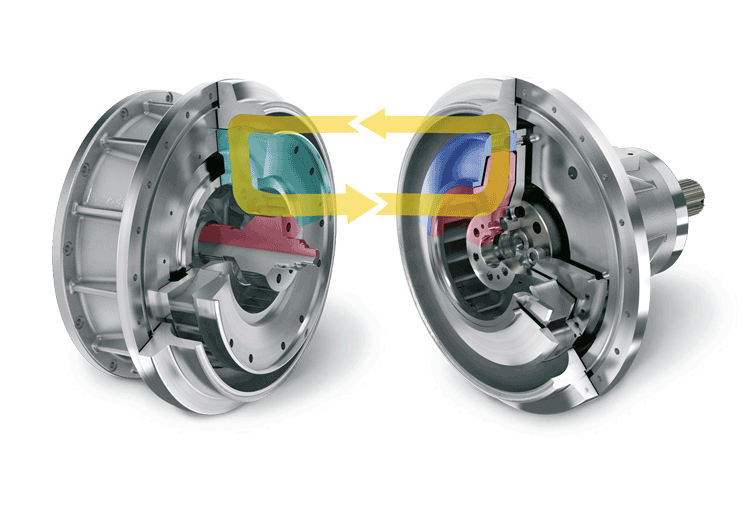

How torque converters work

Torque converters are hydrodynamic transmissions invented based on the" Foettinger Principle. "They transmit the torque of the driving motor wear-free and steplessly, within a closed circuit.

This closed circuit consists of a pump, turbine, and guide wheel with optional adjustable guide vanes. The pump wheel converts the motor's mechanical energy into kinetic fluid energy. In the turbine wheel, this kinetic energy is converted back into mechanical energy and transmitted to the output shaft. The adjustable guide vanes regulate the mass flow, which results in variable output speed.

Our portfolio

Type E...

-

Fixed guide vanes with different characteristics

Type EL…

- Adjustable guide vanes for accurate speed control

Optional:

- Filling and draining valves, gears, and turning device

Key technical data

| Power | Up to 100 MW | ||

| Output torque | Up to 110,000 Nm | ||

| Input speeds | Up to 3,600 rpm |

Applications

Gas turbine starter

Gas turbine starter

With abundant torque available, the torque converter can quickly accelerate the gas turbine to and above its self-sustaining speed. This is essential for state-of-the-art, high-temperature gas turbines requiring high torque at low output speed.

Other functions include:

- Turning of the gas turbine utilizing the integral turning gear for slow-roll functions

- Indexing the gas turbine for inspections

- Fast spin-cooling of the gas turbine for ease of maintenance

- Extended gas turbine water-wash cycles

Subsea pumps

Subsea pumps

Compact and simple in design, this space saving torque converter is a reliable solution for challenging subsea applications. Integrated inside the pump, the converter regulates the speed of the pump. The complete unit is installed on the seabed and apart from an electrical supply system, it does not need any other supply lines. This converter paves the way for improved profitatbility against the background of decreasing flow rates at existing wells and increasing distances at expansion wells. The investment cost can be reduced by up to 70%, when factoring in heavy and space-intensive platform equipment costs.

Test field drives

Test field drives

This high power density, small footprint, and compact torque converter are used in power applications of up to 65 MW. Type EL... torque converters have adjustable guide vanes and are ideally suited to test field drive applications. Decoupling the motor from the driven equipment allows for an unloaded motor start. The torque converter provides full torque instantaneously, even if the output is blocked, and can be started quickly without any significant inrush current and grid impact. Most importantly, speed and torque are controlled accurately and smoothly. Designed for at least 30 years, these units guarantee worldwide spare part availability.

Additional applications

Additional applications:

- Volumetric pumps

- Extruders

- Agitators

- Chain conveyors

- Winches

Packaged starters

Packaged starters

Your complete system solution

This all-inclusive solution reduces site assembly, alignment, and commissioning time as the components of the packaged starting system are selected to complement each other, achieving an economical and space-conscious design.

The torque converter, motor, and all required accessory equipment are factory mounted onto a common base. For more demanding requirements, such as retrofitting a unit to an older gas turbine, a self-contained packaged starter design can include an integral oil tank. Additionally, an optional onboard PLC system can be fitted to control the various phases of the starting sequence. Furthermore, the driver (motor) can be used above its continuous rating during the short start-up of the gas turbine. When designed as a true starting motor, the driver will be smaller, space-saving, and more economical.

Contact our experts

References

The revolutionary pump drive and subsea coupling system

Voith has partnered with Fuglesangs Subsea to develop an advanced pump drive and coupling system, leading to outstanding reliability and substantial cost savings. By integrating a Voith torque converter into the pump on the sea floor, electrical variable frequency drives on the topside are no longer required for speed control.

Perfect control – From 100 kW to 65,000 kW

Efficient and reliable speed control of motor-driven machines is crucial to various industries and applications. Our solution includes a range of variable speed drives (VSDs) that keep your systems running at optimum speed.