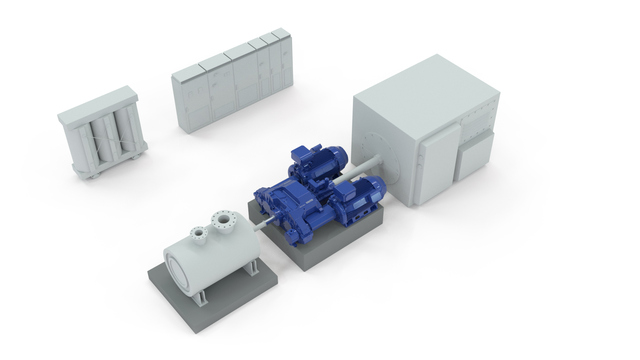

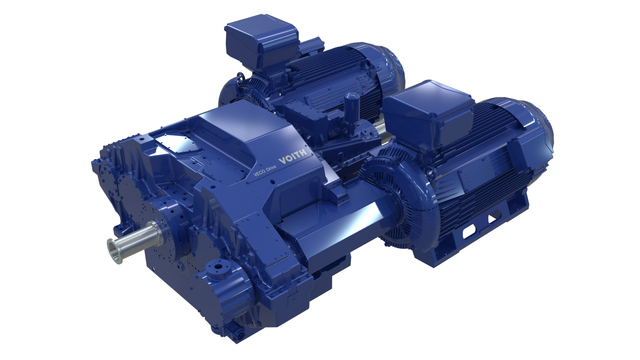

Highest efficiency with the smallest footprint

The ideal speed regulation solution for high-speed rotating equipment that saves energy and reduces CO2 emissions, the VECO-Drive, achieves this high operational efficiency by operating an electrically controlled superimposing planetary gear with frequency-controlled servo motors. As a result, a small amount of rated power ensures a record efficiency of more than 97%.

All benefits at a glance

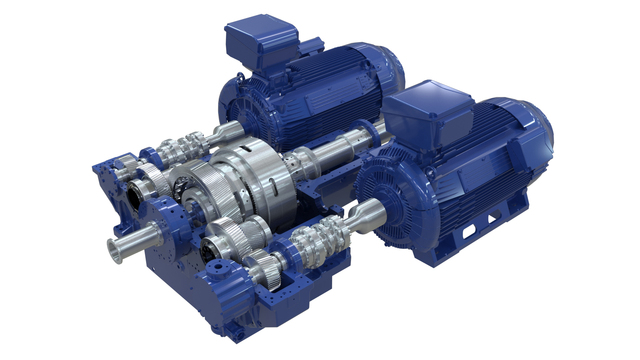

How the VECO-Drive works

Motor start

Direct online start (type RE)

Direct online start with VECO-Drive RE

The main motor is started directly online (DOL). Simultaneously, two servo motors accelerate the driven equipment smoothly, thus ensuring a rapid start-up and a reduced main motor load.

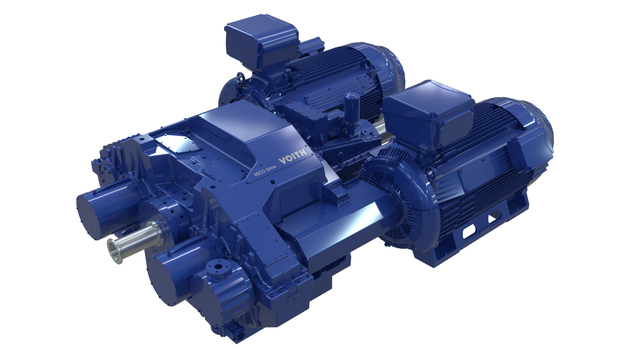

Soft motor start (type REC)

Soft motor start with VECO-Drive REC

This type uses two servo motors as an alternative to a direct online start. Large voltage fluctuations are avoided using the two servo motors as soft starters; this is highly recommended when large drives are connected to a weak grid.

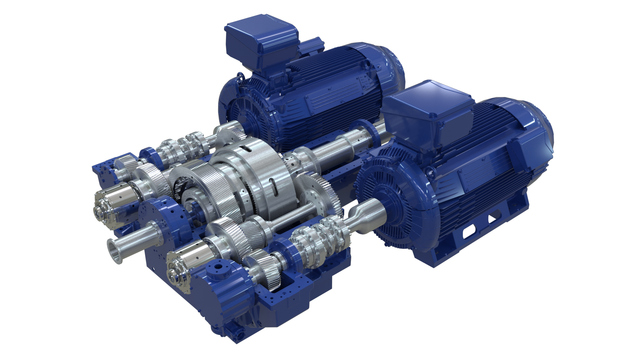

Key technical data

- Rated power: 4 MW – 15 MW

- Input speed: 1,500 rpm or 1,800 rpm

- Rated output speed: 5,000 rpm – 15,000 rpm

- Speed range: 70% - 105% (compressors), 50% - 100% (pumps)

- Installation: Ex, non-Ex

References

In February 2020, the first two VECO-Drive units were successfully commissioned and put timeously into commercial operation. Processes have been running smoothly and efficiently at a thermal power plant in Guangzhou, China, with all tests onsite passed with distinction and fulfilling the customer’s expectations.

Currently, the two VECO-Drive units drive the boiler feed pumps and form part of an energy-saving transformation project.

Voith Service – how can we help you?

- Everything from a single source: development, design, production – and service!

- Decades of product experience as an original equipment manufacturer and service provider

- Fast and smooth cooperation and best service thanks to a worldwide network of service locations

- Long-term partnership and planning security are guaranteed due to longstanding corporate stability