Optimize Your Hydraulics with Smart, Energy-Saving Pump Technology

Voith's hydraulic internal gear pumps, used in various applications up to 420 bar, ensure high efficiency and low-pressure pulsation. Their overall efficiency is often 5 to 10% better than comparable pumps, ideal for constant and variable speed drives. Available options include single pumps, pump combinations, motor pump units, valiable speed pumps, and servo pumps.

Benefits at a glance

Check out the picture below to see all the benefits at a glance and discover how Voith can enhance your hydraulic systems! How can these features improve your current setup?

420 bar

Peak pressure up to 420 bar

> 90%

Overall efficiency of over 90%

5

Multiple flow pumps combined out of up to 5 single pumps

45 dB(A)

Low noise emissions

Cost-efficiency

Reduction of operating costs

Good pulsation behaviour

Highly precise control

Product details

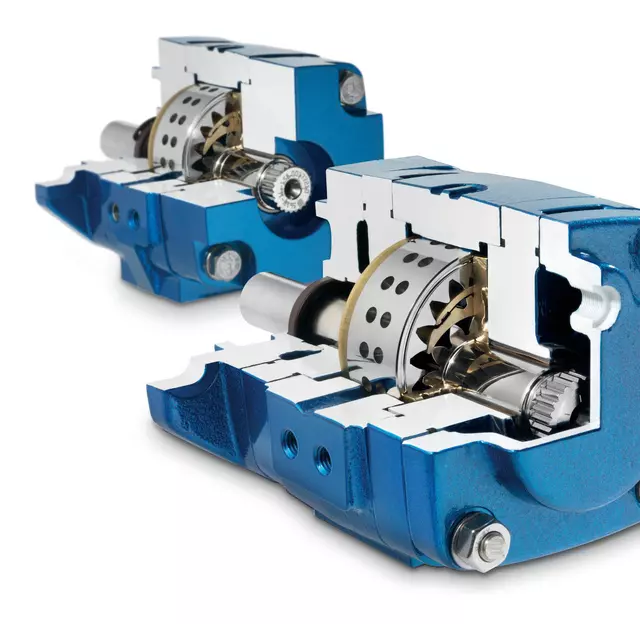

IPS

The IPS internal gear pump was developed for variable-speed drive applications. The performance range is up to 345 bar peak pressure and a maximum displacement volume of 252 cm³ per revolution.

IPV

The IPV internal gear pump was developed for constant-speed drive applications. The performance range is up to 345 bar peak pressure and a maximum displacement volume of 252 cm³ per revolution.

IPVS

The IPVS internal gear pump was developed for constant-speed drive applications. The performance range is higher than the IPV pump and goes up to 420 bar peak pressure and a maximum displacement volume of 252 cm³ per revolution.

IPH

The IPH internal gear pump was developed for special constant-speed drive applications. The performance range is up to 330 bar peak pressure and a maximum displacement volume of 126 cm³ per revolution.

Areas of application

Voith's hydraulic internal gear pumps are versatile and efficient, making them suitable for a wide range of industries and applications. Below, you'll find key areas where these pumps can be effectively utilized to enhance performance and reliability.

Variable speed pumps

Variable speed pumps

Variable speed pumps in their simplest version are frequency-controlled. They consist of three main components:

- Variable frequency drive (VFD)

- Asynchronous motor

- Voith internal gear pump

Using a variable speed pump system is extremely simple. You provide us with all the machine or system cycle data. We then use this information to determine the necessary pressures and volume flows, and design the pump systems. The final pump solution you receive is a complete solution, as it is customized, ready to run, and all from a single source.

Servo pumps

Servo pumps

For hydraulic systems that place high demands on control engineering, servo pumps are the perfect solution. The basic version of these pump systems also consists of three main components:

- Servo inverter

- Synchronous servo motor

- Voith internal gear pump

Servo pumps control the pressure or the volume flow. They precisely convert electrical energy into the hydraulic energy that is currently needed in the system. The classic use of valves for control can be either completely or partially omitted. This considerably simplifies every hydraulic system.

Total cost of ownership (TCO)

Conventional hydraulic systems usually have constant volume flows. As a result, these systems have virtually constant energy consumption. Using servo pumps makes it possible to vary the volume flows in hydraulic systems. In the part load range and outside the machine cycle, the servo pumps operate at lower speeds or stop altogether. Servo pumps reduce the energy consumption by up to 70 percent. Using servo pumps can reduce the total cost of ownership (TCO) for the hydraulic system by up to 35 percent. Systems with variable speed servo pumps are amortized in a short timeframe – in most cases, within 1 to 2 years.

Energy efficiency

Comparison of plastics injection molding machines with different hydraulic systems

Cycle of a plastics injection molding machine:

| Pump: | Fixed displacement pump |

| Drive motor: | Constant speed asynchronous motor |

| Control modes: | Using classic valves only |

| Energy consumption: | 100 percent |

| Pump: | Variable displacement pump |

| Drive motor: | Constant speed asynchronous motor |

| Control modes: | Partial use of classic valves |

| Energy consumption: | 70 percent |

| Pump: | Voith servo pump |

| Drive motor: | Variable speed synchronous servo motor |

| Control modes: | Partial or total servo pump control |

| Energy consumption: | 30 percent |

Drives

Based on multiple criteria, a drive with Voith servo pumps is better than other drive types. Injection molding machines using Voith servo-pump drives feature low total cost of ownership (TCO), reliable processes and high productivity.