H2 transformation for a sustainable and stable future

Your innovative product portfolio and long-term added value — that's what we focus on.

Therefore, we develop customized, highly efficient, and safe hydrogen storage solutions that strengthen your competitiveness.

From the core product to successful application, we support you with expertise and commitment. Together, we create the conditions for a smooth integration of hydrogen — the key energy source of tomorrow — and actively drive progress in your industry.

Find out how to maximize the benefits of your products

Use our H2 chatbot or scroll down to explore the fascinating topic of hydrogen storage.

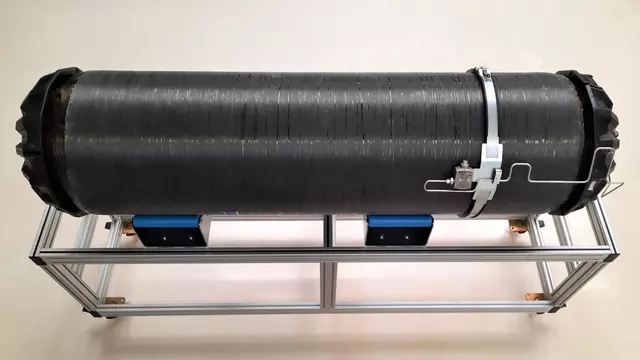

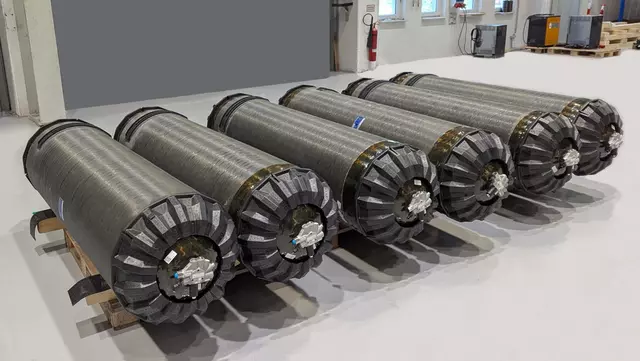

The 700 bar and 350 liter H2 tanks are manufactured using our unique towpreg filament winding process.

All in one modular hydrogen storage system that is compatible with H2 combustion engines or fuel cells.

Why is hydrogen the future?

Hydrogen is a clean fuel for vehicles, provides energy for households, and supports industrial processes. Efficient storage technologies, such as Type IV high-pressure tanks, enable hydrogen to be used as a reliable and environmentally friendly alternative to fossil fuels.

What is hydrogen storage?

Hydrogen storage refers to methods for the safe and efficient storage of hydrogen for use as an energy source. Proper hydrogen storage is an important step toward a sustainable and emission-free future. Suitable H2 storage systems supply hydrogen to heavy commercial vehicles such as trucks, for example, and contribute to the decarbonization of the transportation sector.

What are the methods for storing hydrogen?

There are four main methods for storing hydrogen:

Efficient hydrogen storage is important for its use as a clean energy storage medium. As technology advances, storage methods are becoming more effective and cost-efficient, promoting the use of H2 as a sustainable energy option.

Which materials are best for storing hydrogen?

The choice of the best material for storing hydrogen depends on the application, storage density, and safety requirements. The three main materials are:

High-pressure tanks made of carbon fiber

High-pressure tanks made of carbon fiber, such as the Carbon4Tank, are lightweight and strong — ideal for mobile applications. They can safely store gaseous hydrogen at pressures of up to 700 bar (approx. 10 000 psi).

Cryogenic containers made of stainless steel

Cryogenic stainless steel containers with special insulation store liquid hydrogen. It offers high energy density, but is energy-intensive and difficult to handle due to heavy cooling requirements – especially in the automotive sector.

Metal hydrides and solid storage materials

Metal hydrides such as magnesium hydride store hydrogen chemically in solid form and release it again when needed through chemical processes. This method is safe and compact, but often heavier and slower in hydrogen release.

High-pressure tanks are ideal for mobility applications, such as hydrogen-powered trucks. Cryogenic containers are ideal for special applications, such as in aerospace, where hydrogen is used for rocket propulsion. Metal hydrides and solid storage materials are suitable for stationary applications where space and weight are not a major concern, such as in industrial processes. Research and development are continuously improving the efficiency and safety of hydrogen storage.

What is stored hydrogen used for?

Hydrogen storage has a wide range of applications, covering both existing and future technologies. The most important applications are:

The versatile applications of hydrogen storage make it an important building block for a sustainable energy future. The integration of hydrogen storage technologies in various sectors reduces dependence on fossil fuels while increasing energy efficiency and environmental friendliness.

Is hydrogen storage safe?

There are proven methods and technologies that guarantee the safe storage of hydrogen.

Modern storage systems use pressure sensors, pressure relief valves, and robust housings. Regular inspections and strict regulations ensure safety. Numerous individual tests and combined test procedures are required before hydrogen storage systems can be used in vehicles, for example. These include burst, fire, crash, and service life tests. You can find more information on our tank page.

With the right technologies and safety measures in place, hydrogen storage is safe.

What are the challenges of hydrogen storage?

The storage of hydrogen brings with it several challenges. The most important ones are:

Storage efficiency

The aim is to keep the storage space as small as possible while maximizing energy density. This requires high pressures or the liquefaction of hydrogen. Both are possible and depend on the application in use.

Safety

Hydrogen is highly flammable and can form explosive mixtures with the air. Strict safety precautions and high-quality materials like Carbon-fiber reinforced polymer (CFRP) make the use of hydrogen safe.

High costs

Hydrogen as an energy carrier is still in its infancy. As a result, it is currently relatively expensive. Further improvements and economies of scale could lead to significantly lower prices in the future.

Environment

Hydrogen storage technologies must be able to withstand extreme environmental conditions, be corrosion-resistant, and have a long service life. Special materials, such as CFRP, meet these requirements.

Energy consumption

Liquefaction by cooling to -253°C (-423°F) and the compression of hydrogen are energy-intensive processes. The smart use of surplus green electricity could be one possible solution.

Infrastructure

The existing hydrogen infrastructure is not yet sufficiently developed. Significant investment in transport and storage solutions is needed to supply hydrogen in large quantities and enable its widespread use.

About Voith HySTech

Voith HySTech stands for innovative hydrogen storage solutions that are shaping the mobility and energy supply of tomorrow. As part of the Voith Group, we combine decades of CFRP and automotive expertise with state-of-the-art technology.

Our modular storage system for heavy-duty vehicles enables fast refueling in just 10 minutes and offers maximum safety and storage capacity. Thanks to the “plug & drive” concept, our systems can be seamlessly integrated — a decisive contribution to the decarbonization of heavy-duty transport.

Despite market challenges and high expectations, we have managed to offer a certified and safe product with our hydrogen tank that is recognized by leading truck OEMs worldwide. We are Voith HySTech, and we are shaping a zero-emission future - sustainably and safely.

Voith HySTech – for a sustainable, emission-free future.

Resources

News

For hydrogen tanks to be released on the road, the law defines that they must be certified beforehand. In Europe, type approval on H₂ tank systems is governed by the regulation UNECE R 134. Now, for the first time, a Type IV 700 bar and 350 litre hydrogen capacity tank has been approved for road use under the guidelines of the United Nations Economic Commission for Europe.

We're developing recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials. Our focus lies on advancing two distinct recycling approaches in particular: one tailored for recycling of manufacturing scraps, and the other designed for end-of-life (EOL) components like hydrogen tanks. Read more in CompositesWorld's article.

Voith Composites, the Composites 4.0 industry leader and production center of carbon fiber-reinforced composite solutions (CFRP) in the Voith Group, has won the JEC Composites Innovation Award 2022 for the development of the Voith Inline Thruster CFRP rotor blades using Carbon4Stack and Carbon4Tool.

Content

BMW M is an innovator in the automotive industry. While CFRP techniques are slowly being adopted by some auto manufacturers, the BMW Group and BMW M are already realizing the potential of having successfully integrated CFRP parts.

HORYZN is a student initiative focused on real-world use cases for UAVs (Unmanned Aerial Vehicles). The team from TU Munich works collaboratively on the design, development, and implementation of UAVs for social good. Voith Composites was approached to support HORZYN’s latest project, an eVTOL (electric vertical take-off and landing) UAV for medical emergencies, providing its CFRP tooling solution – Carbon4Tool - which has helped the project achieve early success.

Composites 4.0 is part of what we know as Industry 4.0 or more commonly, digital transformation. It enables automation and data exchange in manufacturing technologies within the composites industry. It’s about developing technology to make the best of composite manufacturing - building smart factories and processes that are optimized to reduce waste and cost while increasing the quality of composite parts.

DUQUEINE Group - a world-class manufacturer of composite parts in France - joined forces with Voith Composites to test Carbon4Tool - Voith’s innovative new carbon-fiber-reinforced polymers (CFRP) prepreg material for tooling applications.