Ideal production and warehousing conditions

Cooling systems, ventilation and air-conditioning technology as well as drive components

Voith provides important systems, technologies and components for the reliable, hygienic, safe, and sustainable production of food, beverages and tobacco products.

Process air systems and cooling technology for highest product quality and efficiency

There are strict requirements for climatic conditions and air technology in the production and warehouse area when manufacturing food, beverages, and tobacco products. Voith provides cooling systems and process air systems for the production and warehousing of dairy products, food, beverages, brewery and tobacco products. The scope of delivery also includes state-of-the-art system-oriented automation technology.

Reliable control systems for steam turbines

Steam turbines play an important role as efficient prime movers, ensuring process quality in the food processing industry. With a proven track record, our range of actuator and control systems ensure reliable and precise control of steam turbines.

Customized fabrics and roll covers

With roll covers made of various materials and high-tech fabrics, Voith provides high-quality solutions for the food processing industry. Leading-edge technology and efficient processes ensure high reliability. We deliver value-added solutions for your specific requirements.

Our products for the food, beverage and tobacco industry:

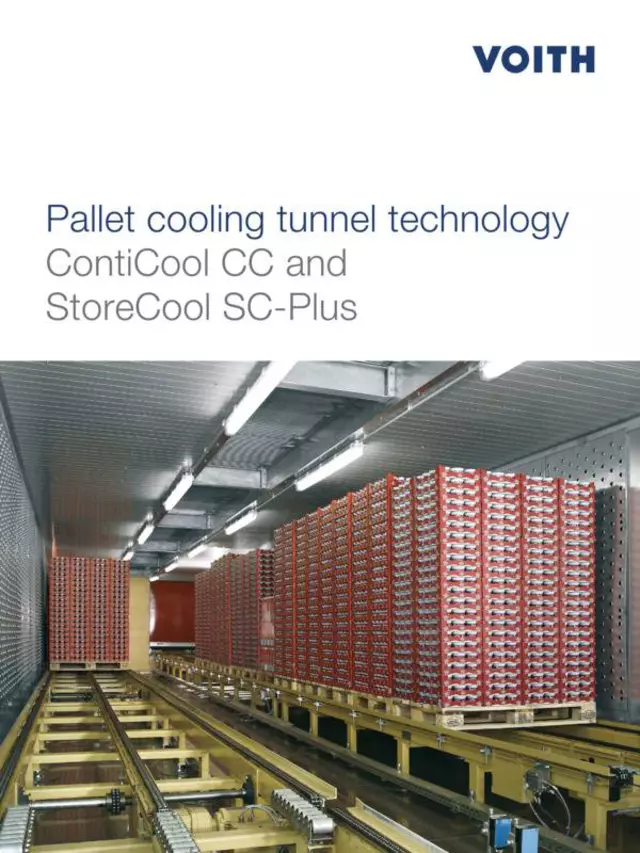

- Pallet cooling: cooling tunnels, cooling cells, rapid-cooling bays for warehouses

- Fermentation and ripening rooms

- Air technology for high-bay warehouses

- Room and process air technology

- Air conditioning and ventilation for special process areas

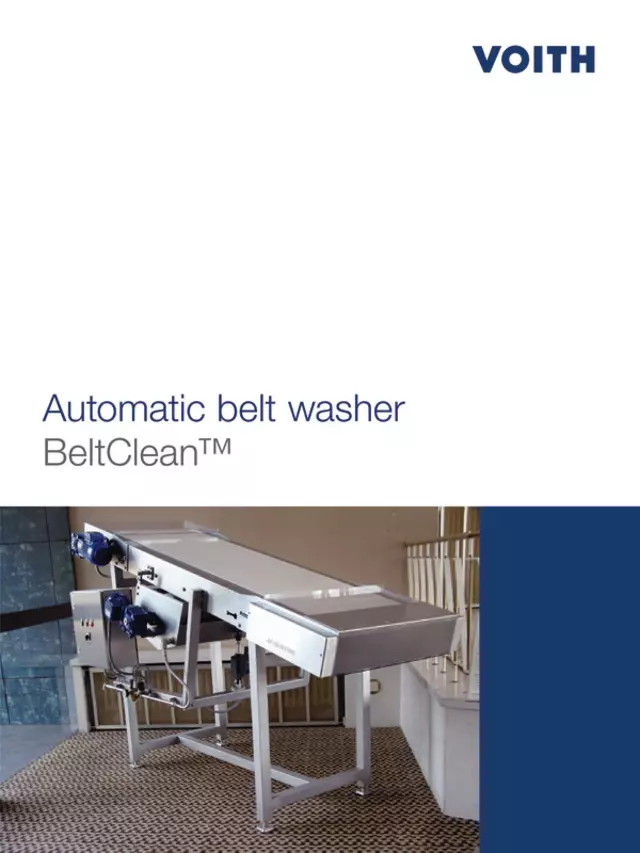

- Conveyor belt cleaning

- System-oriented automation technology

- Actuators and control systems

- Hirth serrations

Pallet cooling, process air technology, fermentation and ripening rooms for dairy processing

Dairy products must be cooled down a certain way after being filled in order to achieve the desired product quality along with a precisely definable, long shelf life. In fermentation and ripening rooms for producing specific dairy products, room air conditions need to be kept within narrow tolerance ranges. Voith provides the dairy-processing industry with tailor-made solutions for pallet cooling (cooling tunnels, cooling cells, and rapid-cooling bays) and for fermentation and ripening rooms.

Air technology for high-bay warehouses, process air technology and pallet cooling for food production

High-quality, microbiologically impeccable foods require a hygienically perfect production environment. Product-specific room conditions are extremely important when storing sensitive products. Voith provides room and process air technology systems for production, further processing, and warehousing.

Air conditioning and ventilation for beverage producers and breweries

When producing beverages, it is necessary to ensure hygienically perfect production conditions. Intelligent air technology concepts are indispensable for meeting the ever increasing requirements and output levels. From the brewhouse to filling and warehousing, Voith offers innovative and energy-saving air technology system solutions.

Room and process air technology for tobacco processing and warehousing, drying systems for reconstituted tobacco

The hygroscopic properties of tobacco require defined indoor climate conditions during processing. From raw tobacco to the finished goods warehouse, it is essential to preserve elasticity and aromas and comply with high hygiene standards in order to maintain uniformly high product quality. Voith has many years of competence in process and mechanical engineering and is therefore able to provide optimized air and climatic solutions. Energy-efficient drying systems with the required process air technology and heat recovery are offered for producing reconstituted tobacco.

Reliable drive components

Achieving exceptional efficiency and operational reliability is easy, when using our Voith Hirth serrations, actuators, protection equipment and control systems. Utilized extensively in sugar factories, in palm oil refineries, distilleries and in numerous other food and beverage applications, our products have a proven track record in the food processing industry.

Roll covers and fabrics for production machines

Our cutting-edge technology and efficient processes ensure a high level of reliability when manufacturing high-quality products. These are sustainable solutions that are specially fitted to your requirements.

Contact us

Air systems contact

Torben Schlieckau

Sales & Product Management Air Systems

Dr.-Hans-Frisch-Str. 4 95448 Bayreuth Germany

t +49 921 293 0 Send an email