Powering the path to autonomous mills

Welcome to the future of papermaking.

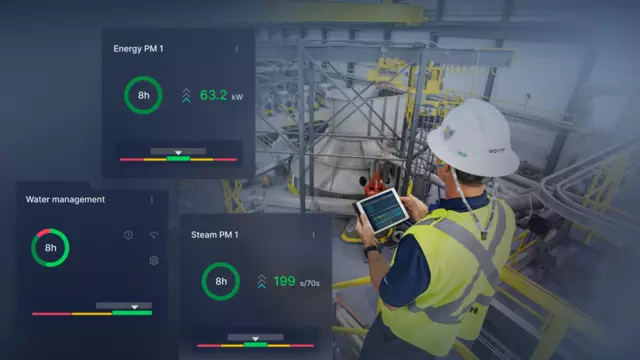

Meet MillOne, our innovative ecosystem that empowers paper mills worldwide by integrating advanced automation and artificial intelligence to enhance human expertise and streamline production processes. Thanks to real-time data analytics, predictive maintenance, and smarter decision-making, it can make your mill more productive, reduce costs, and increase profitability.

At the heart of our approach is a commitment to sustainability and efficiency. We want to ensure that resource use, waste, and energy consumption are minimized. With MillOne, we’re shaping the future of the industry, fostering collaboration and growth as we move toward a more high-performing papermaking world.

Meet the faces behind MillOne

Behind every innovative solution is a dedicated team committed to driving change. Meet the experts and visionaries who are shaping the future of the autonomous paper mill. Their passion, expertise, and collaboration are the driving force behind MillOne, ensuring that every step forward creates a meaningful impact.

Mondi’s leap to autonomy:

Smarter mills, stronger results

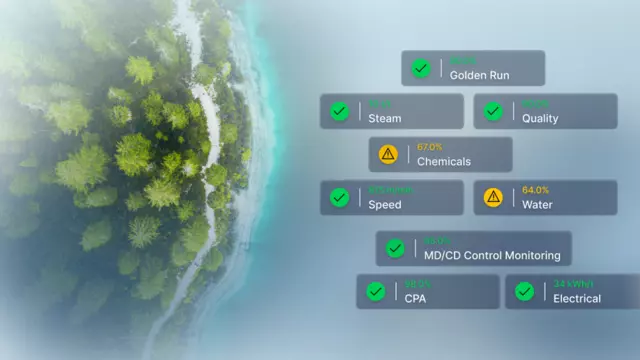

As the first mill to implement MillOne, Mondi has taken a bold step toward autonomy—and the results speak for themselves. By seamlessly connecting systems, optimizing operations, and enabling KPI-based production management, MillOne has transformed daily workflows. Task management is now fully integrated across all shifts, with adoption exceeding expectations within the first six months. Operators have embraced the system, striking a balance between system-generated tasks, manually created assignments, and efficient task resolution—without accumulating backlogs. Mondi’s success demonstrates how smart automation leads to stronger results, setting a new standard for mills on their journey to autonomy.