Increased productivity and reliability even in harsh environments

Voith's conveyor components are extremely robust, safe, and engineered to the highest standards. Our products have an excellent track record for reliable operation in harsh surroundings. At the same time, they are characterized by minimal maintenance and low wear. The mean time between failure (MTBF) of our components sets the benchmark in the mining industry.

Key components for belt conveyors

With more than a century of experience working with conveyor products in mining, we offer customized solutions for mining conveyor technology. Discover our latest solutions for intelligent drive components designed to operate in innovative, automated network systems!

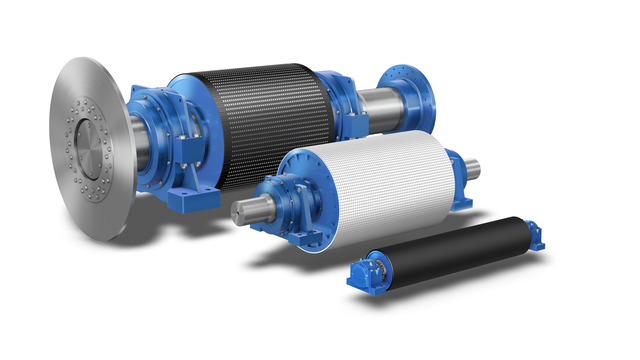

Voith Pulleys

The Voith Pulleys can be used in all belt conveyor systems.

High efficiency and reliable operation

With excellent running characteristics, even under extreme conditions such as heavy loading, heat, cold, and humidity, Voith Pulleys are an indispensable element in belt conveyors for material handling and are built to last. Consequently, they substantially reduce maintenance and repair costs over the system's lifetime. The layout and calculations are customized and consider the corresponding environmental influences in the application area. This procedure guarantees the implementation of conveyor belt pulleys that have undergone engineering optimization.

Features and benefits

- Pulleys engineered for optimum operation of the conveyor

- Excellent running characteristics for high system availability

- Highest quality materials and components

- Highest quality manufacturing

- Extremely long service life

- Easy maintenance

- Explosion protection, according to ATEX

Voith TurboBelt TT Linear Booster Drive

The Voith TurboBelt TT Linear Booster Drive is typically used in underground and open-cast mining belt conveyor systems.

Discover significant cost savings in belt conveyor systems

A powerful and productive intermediate drive for belt conveyors, the Voith TurboBelt TT Linear Booster Drive, improves conveying efficiency by extending the service life of belts, saving belt costs in new conveyors, and increasing capacity in existing systems.

The top belt of the primary conveyor system (carrying belt) rests upon the top belt of the introduced TT Drive (drive belt). The drive is assembled directly within the current conveyor system. Equipped with a head and tension station, the TT Drive is integrated into the actual belt. The tensile force is then transferred linearly using the friction lock between the carrying and drive belt. This results in significantly lower belt tensile forces. Voith TT Drives provide benefits when used with medium, long, or inclining belt conveyors.

Features and benefits

Easy length adaption of conveyors in coal haulage pathways

- Fewer transfer stations

- Reduced dust formation

- Reduced height requirements

Use in high-capacity belt conveyors

- A lower belt rating needed

- Smaller drive units

- Easier maintenance

Use in existing belt conveyors

- Increase in conveying capacity

- Use of existing drive and belts

TT Linear Booster Drive working principle

Voith TurboBelt Transfer Station

The Voith TurboBelt Transfer Station is used in bulk-material conveyor systems at the transfer points.

Fully developed transfer technology

Used in conveyor systems, the Voith TurboBelt Transfer Station provides a sliding, centered material transfer that protects the belt and generates less dust. This reduces maintenance and repair costs when handling bulk materials while also increasing the lifetime of the belt. Thanks to its compact design and modular system, the TurboBelt Transfer Station can be used at almost any operating point, including the appropriate feeding station.

Through our extensive experience, we have developed comprehensive knowledge that we apply in matching material flow and material transfer.

Features and benefits

- Less stress on the belt leads to a longer belt conveyor lifespan

- Sliding transfer protects conveyed bulk material

- Customized design for optimized material flow

- Increased productivity due to optimized material flow

- Increased safety

- Little dust generated

Voith TurboBelt Tension Station

The Voith TurboBelt Tension Station provides the required belt tension and dampens dynamic motions.

For high operational reliability and a longer belt lifespan

The tension station provides the required belt tension and dampens dynamic motions. Based on the belt quality and the belt conveyor system's length, the required appropriate dimensions of a tension station are determined. The Voith TurboBelt Tension Station always sets the correct tension for the belt while optimizing according to changing environmental conditions. In this way, our tension station ensures high operational reliability and a long belt lifespan in underground and open-cast mining.

Features and benefits

- Tensioning systems adapted to conditions

- Systems for underground and open-cast mining

- Tension adjustments without structural changes to the whole system

Voith TurboBelt Storage Loop

The Voith TurboBelt Storage Loop is used in long adjustable underground conveyor belt systems.

Increasing the productivity of expanding conveyors

Belts often need to be shortened or lengthened with relative ease to keep pace with the rate of mining advancement. The Voith TurboBelt Storage Loop System facilitates changing the length of belt systems safely and efficiently. The conveyor belt is looped around 2-6 return pulleys, with 1-3 pulleys mounted on a moving tensioning car. The car is moved using a tensioning mechanism (e.g., a winch) based on the belt length needed. While doing this, the tensioning force is applied in a controlled manner.

Pressure sensors in the Voith TurboBelt Storage Loop ensure dynamic control and monitoring of the belt tension. In this way, they contribute to an overall increase in operational reliability and safety.

Features and benefits

- Minimal belt connectors

- Reduction of downtime by quick and easy lengthening or shortening of the belt

- Compact design due to optimal matching of the needed change in length

Intelligent mining

Voith Service – How can we help you?

Every day holds new challenges and we help you master them successfully. Anytime. Anywhere. Please click on the icon to find out more about our belt conveyor drives & components services.

24/7 Emergency Helpline

Are you in need of emergency assistance? Our helplines are available around the clock.

t +49 7951 32 1616

Voith services all brands

Furthermore, our trained technicians are skilled in the servicing of other manufacturer brands.