Process ServicesFocus on processes

Our process services are tailored to the individual needs of our customers and are performed by qualified engineers and analysts.

With our comprehensive measurement and diagnostic capabilities, our audits, our consulting and targeted training, we identify your improvement potential and support you in implementing improvement measures.

Measuring & Diagnostics

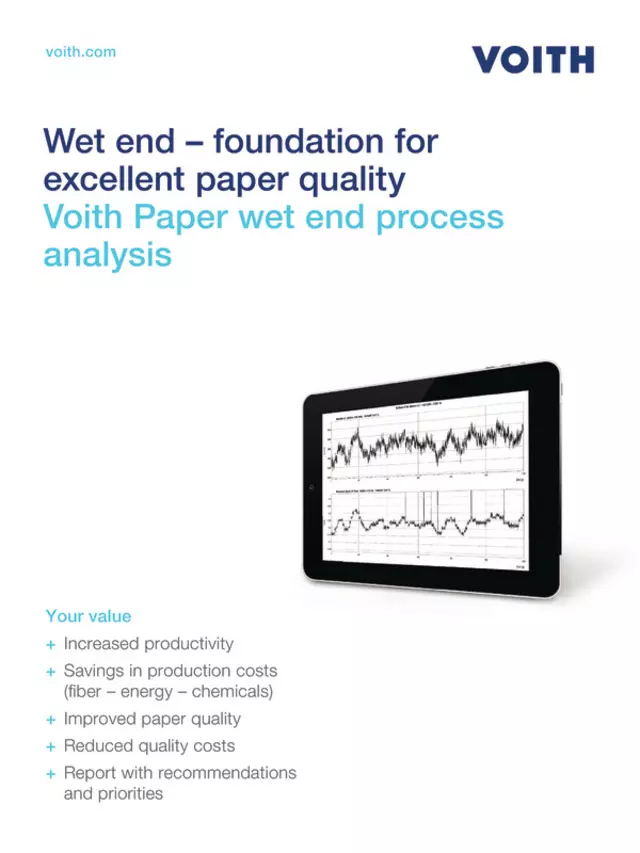

We know your potential! Do you? Problems on a paper machine are not always immediately obvious. Our specially designed analytical systems, closely combined with the many years of experience of our Voith service personnel, help you to identify problems in good time, analyze them and solve them as a next step. As a result, costs can be optimized and shorter downtimes achieved, while ensuring greater productivity.

Our tailor-made measuring and diagnostic services have been specially developed for the requirements of paper production. Whether for mechanical or process measurements, we help our customers with an extensive product portfolio for the whole paper production line, from stock preparation to the winder. In addition, we offer various service packages you can completely rely on.

Our M&D portfolio:

- 3D scan

- Alignment service

- MobiLab

- Paper moisture profile analysis

- Paper profile analysis (Tapio)

- Nip load measurement

- SpeedUp certificate

- Vibration analysis

- Wet end process analysis

- Voith Paper consulting

Audits

Leading mills today know that measurement and analysis are essential for their business success.

Voith has developed standardized methods to measure, benchmark and analyze processes, enabling papermakers to set both physical and organizational key performance indicators (KPIs). We present recommended actions based on facts and delivered in an understandable and structured way. We identify gaps and provide innovative ideas for improving processes, efficiency and safety. Also, we are happy to support the implementation.

- Production line (stock preparation / paper machine)

- Maintenance

- Digitalization

- Energy

- Machine safety

- IT security

- Voith Paper consulting

Expert support and consulting

Fast support for maximum productivity. Our service experts assist you anytime and anywhere. We support you on-site, via telephone, VPN or video and with our remote service center – the OnPerformance.Lab.

OnPerformance.Lab supports you in using digitalization profitably. To this end, process and machine data are continuously analyzed using data mining methods and artificial intelligence supplemented by technology and automation expertise. In combination with the industry-specific paper know-how of Voith experts, potential for improvement is then identified and tapped.

With our consultancy offering we would like to assist you on your improvement process to achieve maximum sustainability of your results. This can be the basis to develop further result orientated service partnerships – our closest contribution to your success.

OnPerformance.Lab

- Smart monitoring

- Data analytics

- Condition monitoring

Voith Paper consulting

- Technology

- Maintenance

- Engineering

- Automation

Training

Proper training of operators and maintenance staff is vital to safe plant operations, and it is a notable contributor to productivity.

Voith PaperSchool offers training courses and complete training paths to enhance your personal skills and knowledge in the field of paper production. We provide training from basic to advanced levels at our Voith Training Centers, locally at your plant, and online.

- Equipment

- Operation & technology

- Safety

- Methodology

Pilot trials

Voith Paper Technology Centers are available to customers worldwide for pilot trials under realistic conditions to turn innovations into market-ready solutions.

For all process steps in paper manufacturing, established and new technologies can be tested under conditions similar to those in the production environment. To minimize investment risks, we offer you the opportunity to compare various machine configurations and work with you to determine the ideal concept. All installations are designed to respond flexibly to your specific requirements at all times.

- Increase your innovative strength through pilot trials

- Minimize your investment risks

- Efficiently develop new processes and products

- Reduce costs by optimizing raw materials and production parameters

- Analyze processes without affecting production

- Consult with experienced Voith experts

Downloads

What can we do for you?

Find your local Voith contact person or send us a message with your request

Further information

Experience the Servolution

What is your concern?

Our service offering