OnCare.Health Universal Joint Shafts

Included with the On.Care Health product range, Voith offers an intelligent modular torque measuring system for condition monitoring of cardan shafts and complete drive lines. The torques are picked up directly on the drive spindles by highly precise sensors. The measured torques are transmitted to the processing units, where received signals are stored and analyzed continuously. The results are displayed in simple and illustrative graphs and charts.

Operators are informed about extraordinary events in case any threshold values are exceeded. Due to high resolution signal storage functionality, the process can be analyzed retroactively.

Benefits at a glance

Facilitates reliable production with minimal downtimes

Archives installation history of joints and bearings as well as maximum torque occurrences, which allows an accurate analysis

Analyzes, calculates and visualizes operating data

Enables predictive maintenance via cardan shaft lifetime projection

Ensures operation of equipment according to specification

Records actual system loads and dynamic torque peaks

Customized solutions to meet your requirements

Voith offers three tailor-made solutions:

Torque Meter

Torque Meter DAQ Monitors torque thresholds online, creates characteristic values, forwards information to other system (SCADA, IBA,...)

Mill Monitor

Trending Archives / displays averaged characteristics values of loads

Data Historian Archives / displays hi-res load and process signals

Mill Expert

Product Specific Assessment Correlates wear and fatigue of monitored components to produced materials

Report Generator Automatically provides focused and essential information where needed, when needed

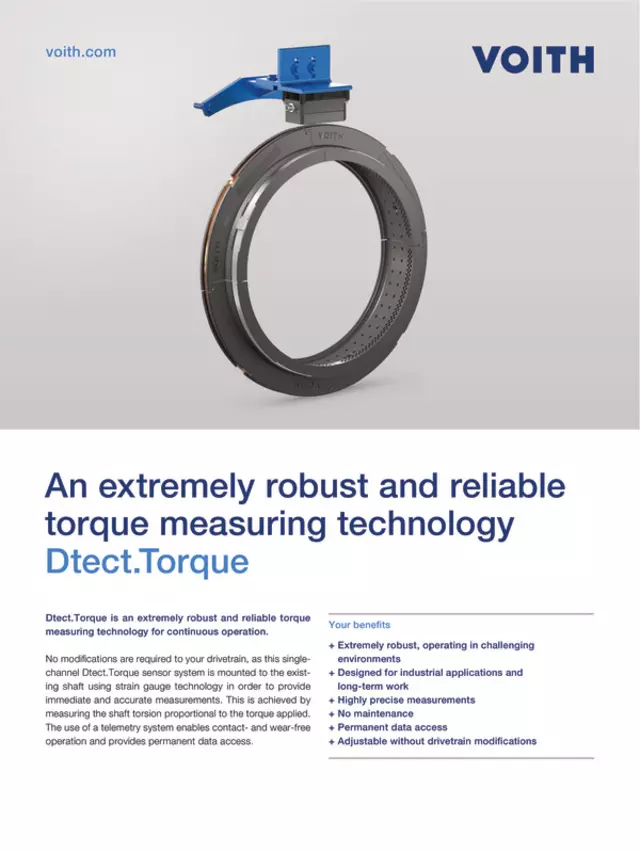

Dtect.Torque

No modifications are required to your drivetrain, as this single channel Dtect.Torque sensor system is mounted to the existing shaft using strain gauge technology in order to provide immediate and accurate measurements.

Designed for extremely high-torque applications

No modifications required to the drivetrain

Permanent data access

No maintenance

Highly precise measurements

Exceptionally robust, long service life