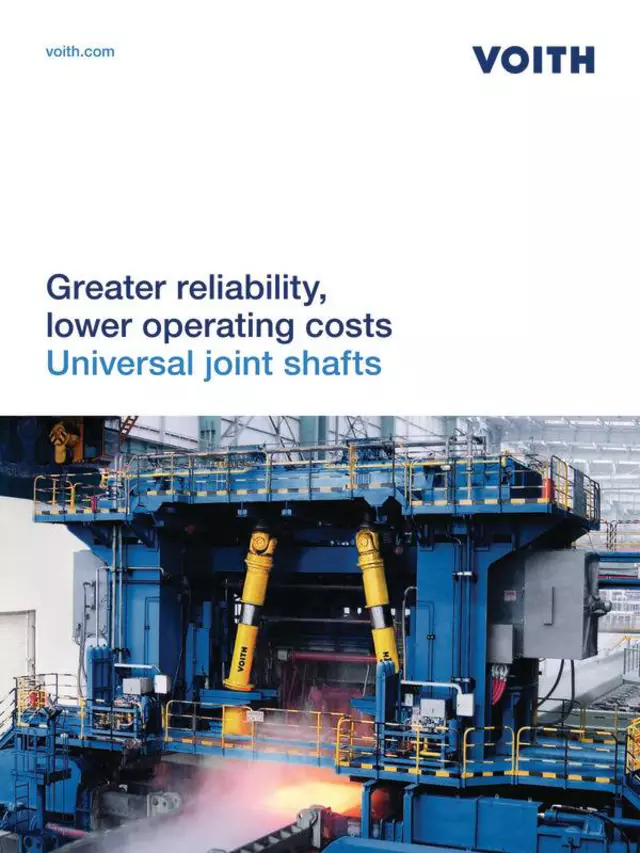

Universal joint shafts

Voith universal joint shafts offer the ideal combination of torque capacity, torsion and bending rigidity. We supply everything from standard universal joint shafts to customer-specific adaptations and custom designs. Our wide range of services includes technical consultation, simulation of torsional vibrations and measurement of operating parameters.

All benefits at a glance

Ease of movement and smooth operation

Low life-cycle costs and long service life

Innovative solution from a single source

Increased productivity & efficiency

Lower CO2-Emissions

High torque capacity even at large deflection angles

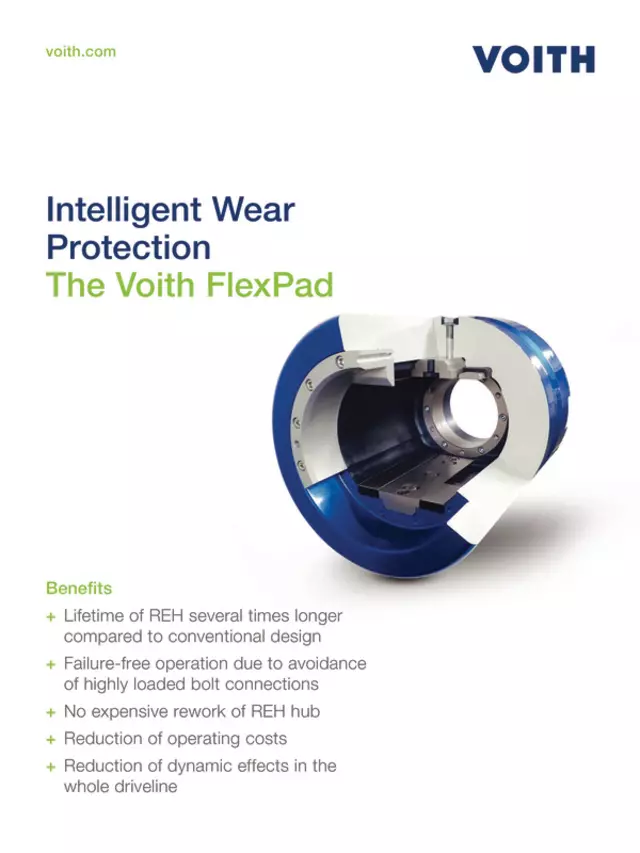

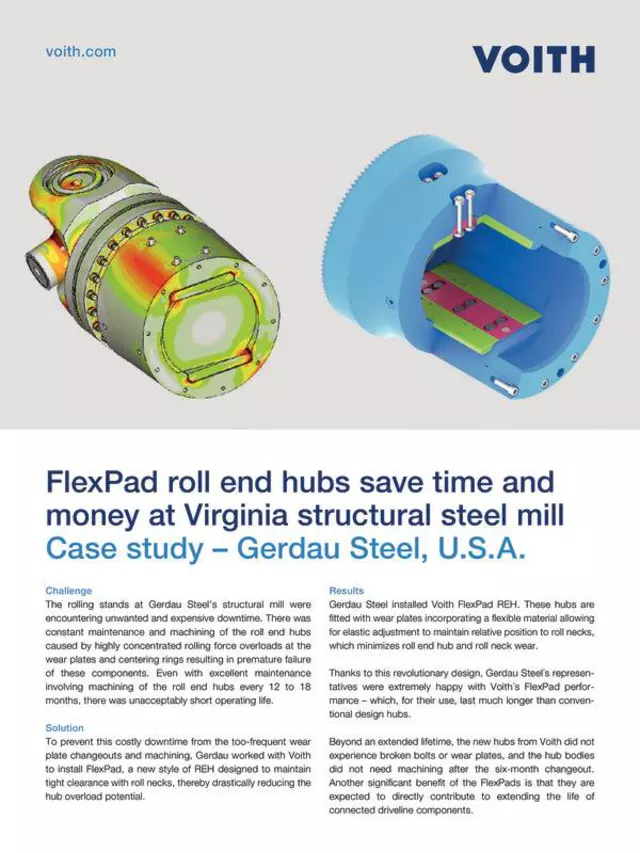

Voith FlexPad

The Voith FlexPad Roll End Hub (REH) design greatly increases hub body operational life through a significant reduction in wear

Voith Service – how can we help you?

Why use Voith Service?

- Everything from a single source: development, design, production – and service!

- Decades of product experience as an original equipment manufacturer and service provider

- Fast and smooth cooperation and best service thanks to a worldwide network of service locations

- Long-term partnership and planning security are guaranteed due to longstanding corporate stability