Pulping

The best-fit technology for each resource

In order to avoid breaking the rejects into too small pieces, it is important for the pulping process to find a balance between the main parameters, such as pulping consistency, temperature, retention time and chemical additives. A low amount of rejects in the pulp makes the downstream process easier and more efficient to operate.

The right machine for every task

| Benefits | Process | |

| IntensaDrum Duo |

High production High reliability |

Drum pulping for recycled fibers |

| IntensaDrum |

Enhanced safety Easy operation |

Drum pulping for recycled fibers |

| BluePulpLC |

Low energy demand Low fiber loss |

LC-Pulping System for recycled paper |

| IntensaPulper |

Flexibility Low energy demand |

Pulping of all kinds of paper and fiber material |

| IntensaPump |

High reliablity High throughput |

Pulper cleaning |

| IntensaMaXX |

High efficiency High reliability |

Pulper cleaning |

| IntensaScreenDrum |

Low fiber loss |

Reject washing |

| CompactPulper |

Low energy demand Small footprint |

Broke pulping for paper machine |

| Ragger |

High reliability |

Pulper cleaning |

Product range

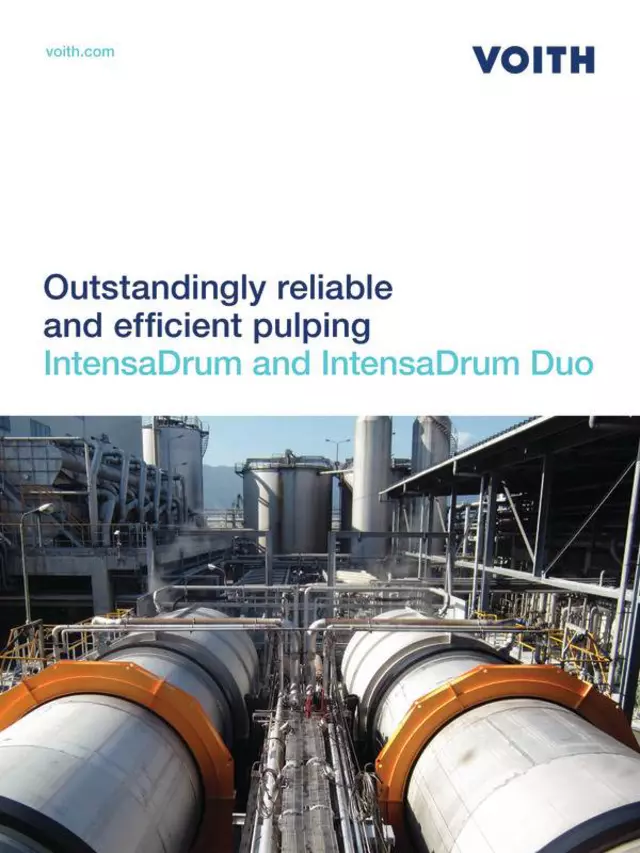

IntensaDrum Duo

With a total length of 78 m and a pulping capacity of almost 3000 tons of recovered paper per day, the IntensaDrum Duo is the largest unit ever built for a stock preparation plant. It consists of a 48 m pulping drum and a 23 m screening drum. In addition to the engineering advantages, the dual-part design offers decisive advantages in terms of operating efficiency and is thus more resource-saving than comparable one-part pulping drums.

Since the specific operating costs decrease significantly with increasing size of pulping units, the IntensaDrum Duo is particularly efficient. Due to their special design, the drums also work in a particularly resource-saving fashion. Just as important as the drum itself is the overall concept of the pulping area. Voith is also breaking new ground here, for example in the discharge of the pre-cleaned pulp from the screening section out of a special flow and thus energy-optimized collecting chest.

The installation of the IntensaDrum Duo at Progroup's Taurus PM 3 project in Germany shows how well it works in practice. With a diameter of 4.5 m each, the 48 m long pulper drum and the 23 m long sorter drum have been processing 3,000 tonnes of recovered paper every day since then. The total length of the IntensaDrum Duo, which weighs over 300 tonnes, is 78 metres. The Taurus pulping plant is thus the largest of its kind in the world.

Discover the IntensaDrum and IntensaDrum Duo via Augmented Reality

To discover the proven IntensaDrum and Voith’s latest innovation IntensaDrum Duo via Augmented Reality, download the IntensaDrum app to your tablet or smartphone. Enjoy the interactive functions by activating the AR mode in the lower right corner and follow the on-screen instructions.

The BlueLine product range from Voith comprises modern machines and products for stock preparation that are characterized above all through the efficient use of energy and other raw materials and by gentle treatment of the fibers.

Discover the innovation bluelineBlueLine Advantages

Higher Runability

Higher Runability

Reduced Fiber Loss

Reduced Fiber Loss

Enhanced Safety

Enhanced Safety

IntensaDrum

Outstandingly reliable and efficient pulping

Voith's IntensaDrum drum pulper consists of one pulping section and one screening section. In the pulping zone, special lifting bars lift the pulp suspension from the bottom and almost to the top. From there, the suspension falls back onto the drum shell. This process is very gentle since there is no rotor to crush or cut the contaminants.

In the sorting zone of IntensaDrum, the suspension is lifted in the same way, and water is added via spray pipes to wash out the fibers through the perforated drum shell. In this way, an efficient separation of fibers and contaminants already takes place inside the pulping process, without damaging the contaminants.

The simple and basic principle of IntensaDrum leads to low maintenance and increased runtimes. Due to its high consistency range, IntensaDrum has a low specific energy consumption, and the lack of wear parts gives a constant accept quality.

Discover the IntensaDrum and IntensaDrum Duo via Augmented Reality

To discover the proven IntensaDrum and Voith’s latest innovation IntensaDrum Duo via Augmented Reality, download the IntensaDrum app to your tablet or smartphone. Enjoy the interactive functions by activating the AR mode in the lower right corner and follow the on-screen instructions.

The BlueLine product range from Voith comprises modern machines and products for stock preparation that are characterized above all through the efficient use of energy and other raw materials and by gentle treatment of the fibers.

Discover the innovation bluelineBlueLine Advantages

Lower Maintenance Cost

Lower Maintenance Cost

Enhanced Safety

Enhanced Safety

BluePulpLC

BluePulpLC

The BlueLine product range from Voith comprises modern machines and products for stock preparation that are characterized above all through the efficient use of energy and other raw materials and by gentle treatment of the fibers.

Discover the innovation bluelineBlueLine Advantages

Higher Runability

Higher Runability

Reduced Fiber Loss

Reduced Fiber Loss

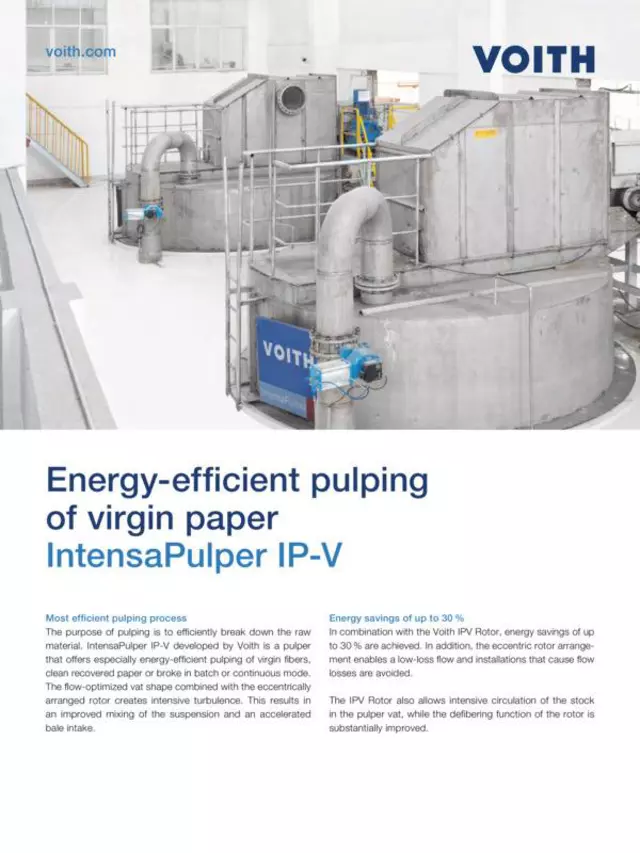

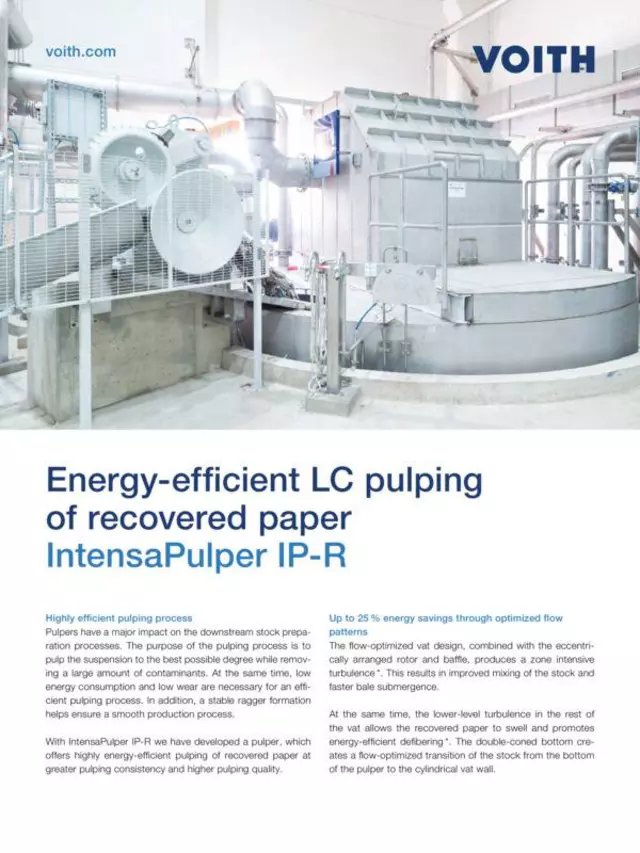

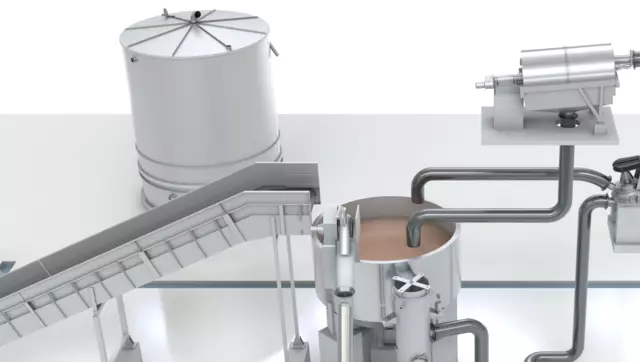

IntensaPulper

Efficient pulping of recovered paper and pulp bales in stock preparation

The Intensa technology from Voith offers quick and intensive mixing of the suspension in the pulper. The flow-optimized pulper vat, in combination with the eccentrically arranged rotor, generates a perfect turbulence. As a result, quicker mixing of the suspension and accelerated bale intake are achieved. The double-coned bottom of IntensaPulper creates a flow-optimized transition from the pulper bottom to the cylindrical trough wall.

IntensaPulper IP-R is specifically designed for the pulping of recovered paper at a high pulping consistency. The rotor configuration ensures a reliable ragger operation, and the number of ragger breaks can be reduced to once a month. The double-coned bottom combined with the baffle urges the coarse heavy contaminants towards the reject discharge allowing a reliable removal in the Junkomat.

IntensaPulper IP-V enables efficient pulping of virgin fibers, clean recovered paper or broke in batch or continuous mode. A bale breaker divides the bales and thus contributes to an increase in production capacity. A trap for heavy parts ensures the separation of wires.

IntensaPulper from Voith achieves a significant increase in production capacity, while keeping the pulping quality consistently high. Significant energy savings of up to 25% are obtained in comparison to conventional low consistency pulpers, thus high cost savings can be achieved.

Environment. Quality. Reliability.

The BlueLine product range from Voith comprises modern machines and products for stock preparation that are characterized above all through the efficient use of energy and other raw materials and by gentle treatment of the fibers.

Discover the innovation BlueLineBlueLine Advantages

Higher Runability

Higher Runability

Lower Energy Consumption

Lower Energy Consumption

IntensaPump

IntensaPump

The BlueLine product range from Voith comprises modern machines and products for stock preparation that are characterized above all through the efficient use of energy and other raw materials and by gentle treatment of the fibers.

Discover the innovation bluelineBlueLine Advantages

Higher Runability

Higher Runability

Lower Maintenance Cost

Lower Maintenance Cost

Lower Energy Consumption

Lower Energy Consumption

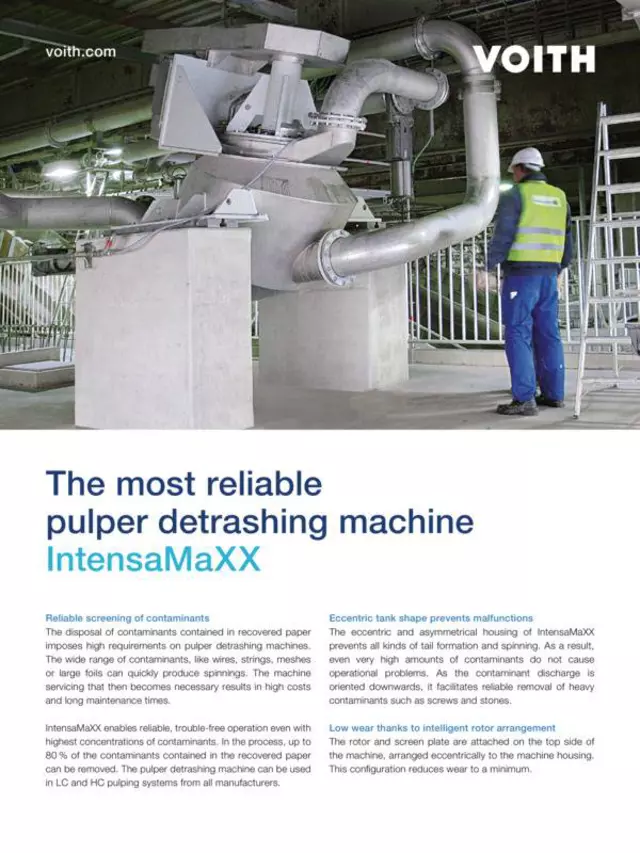

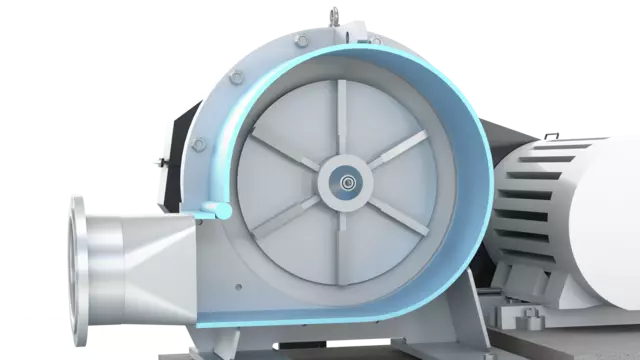

IntensaMaXX

Reliable reject discharge without spinnings

IntensaMaXX can be used in continuous low consistency (LC) pulping with recovered paper grades containing contaminants or in high consistency (HC) pulping as a dumping machine after the batch HC pulper.

The BlueLine product range from Voith comprises modern machines and products for stock preparation that are characterized above all through the efficient use of energy and other raw materials and by gentle treatment of the fibers.

Discover the innovation bluelineBlueLine Advantages

Higher Runability

Higher Runability

Lower Maintenance Cost

Lower Maintenance Cost

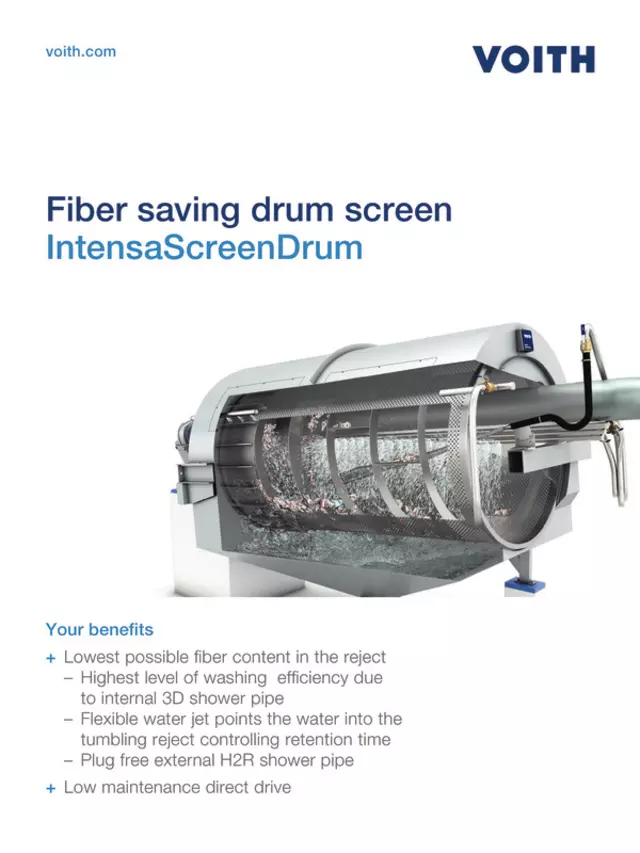

IntensaScreenDrum

Efficient washing for minimum fiber loss

The hood of the IntensaScreenDrum has been redesigned to minimize water vapor and droplets forming on pipes and handrails, keeping the surrounding area clean and safer for the operators.

The reject is purged by intermittent flushing from IntensaMaXX to the IntesaScreenDrum, where it is washed to recover all useable fibers. The internal 3D water spray ensures that all the plastic reject is washed efficiently. By adjusting the water jet, one can optimize the retention time for reject washing, depending on specific conditions for each raw material, system and customer.

The BlueLine product range from Voith comprises modern machines and products for stock preparation that are characterized above all through the efficient use of energy and other raw materials and by gentle treatment of the fibers.

Discover the innovation bluelineBlueLine Advantages

Reduced Fiber Loss

Reduced Fiber Loss

Enhanced Safety

Enhanced Safety

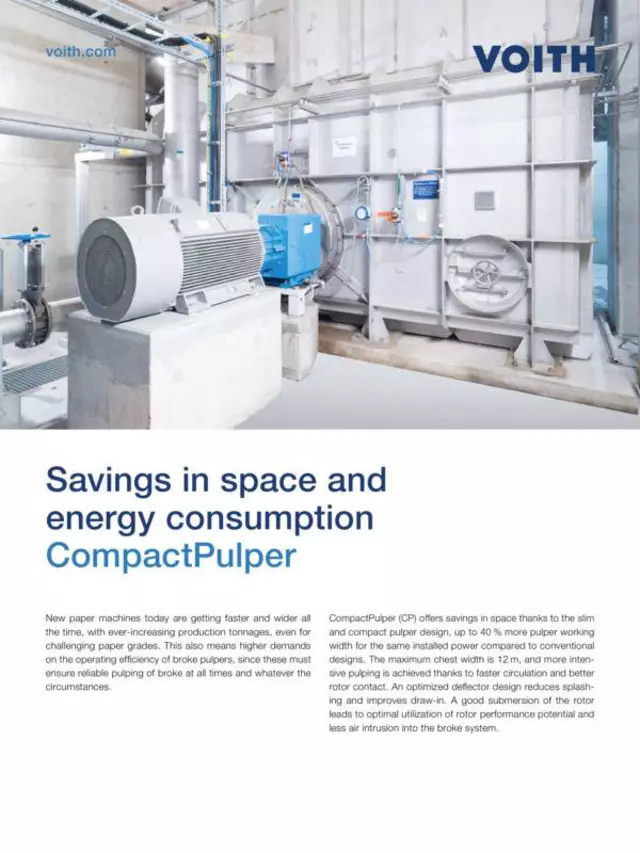

CompactPulper

High operating efficiency with broke pulping

An effective agitation with low vat height, together with an intensive rotor contact results in a higher circulation rate providing a more intensive pulping with simultaneous low energy consumption. The CompactPulper is available with one to four pulping units per pulper vat and with a width of up to 12 meters. Each pulping unit provides an electrical power of between 55 and 900 kW.

Your benefits

- Low space requirement thanks to slim and compact design

- Low energy consumption

- Up to 40% more pulper working width for the same installed power

- Easy assembly

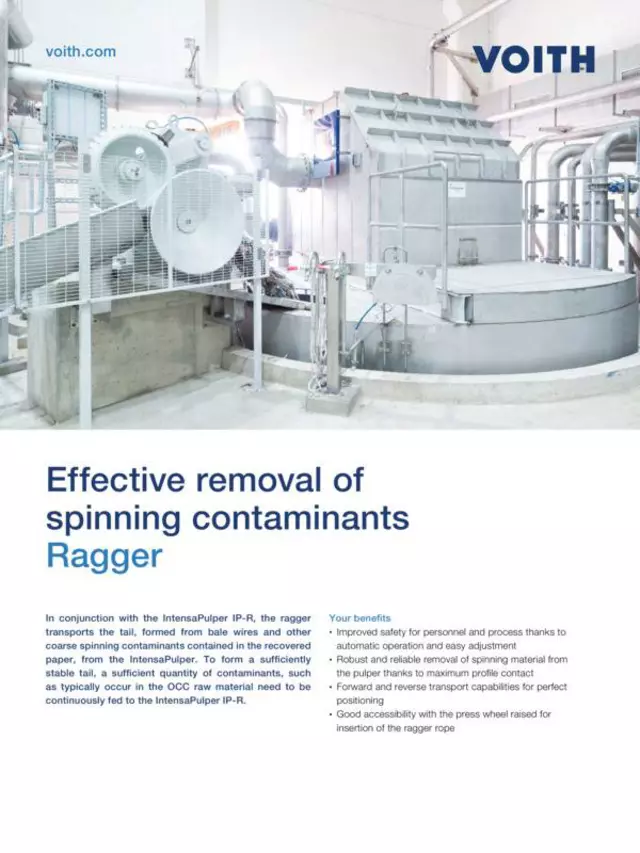

Ragger

Effective removal of spinning contaminants

Bale wires are necessary for the transportation of paper bales but expensive to remove upstream of the pulper, and this is not a functioning solution, because there are still spinning contaminants in the recovered paper that form huge spinnings in the pulper that can only be removed by an orange peel grapple. This is why the ragger is a simple tool for removing the spinning materials from the IntensaPulper IP-R. It ensures that the steel wires are not broken down by the rotor and then cause excessive wear on machines, valves and pumps.

Correctly positioned and in combination with the rotor of the IntensaPulper IP-R, the number of torn off tails can be reduced to a minimum. Strong ribs on the transport wheel prevent slippage.

The ragger produces 1.6 tons of tractive force with a 1.1 kW motor. During breaks in operation the brake integrated into the motor stops the transport wheel from twisting. Forward and backward transportation of the ragger is possible with push buttons. The high gear ratio allows an intermittent speed control from 10 to 300 m/h.

Your benefits

- Improved safety for personnel and machines thanks to automatic operation and easy adjustment

- Robust and reliable removal of spinning material from pulper thanks to maximum profile contact

- Forward and reverse transport possibilities for perfect positioning

Your contact – How can we help you?

Engineered for success

Servolution. Service at the next level

At Voith, the success of the customer takes center stage. Service means delivering customized service solutions and utilizing our full expertise to help our customers reach their goals.

Publications

News

Explore other relevant products and solutions

Voith Paper Newsletter

Always get the latest updates on new products and services, projects, campaigns and success stories as well as upcoming exhibitions and conferences – straight to your inbox.

Subscribe now