Customized hydraulic systems made for you

Your individual requirements continue to be our top priority at Voith, where we customize plug-and-play systems with all components supplied from a single source.

Further peace of mind is guaranteed with our network of global engineers that have over 50 years of experience in these specialized markets: mechanical engineering, sheet metal working, plastics processing machines, press applications, machine tools and energy.

Benefits

- Individual solutions

- Short development times

- High availability

- Fast commissioning

Our product portfolio

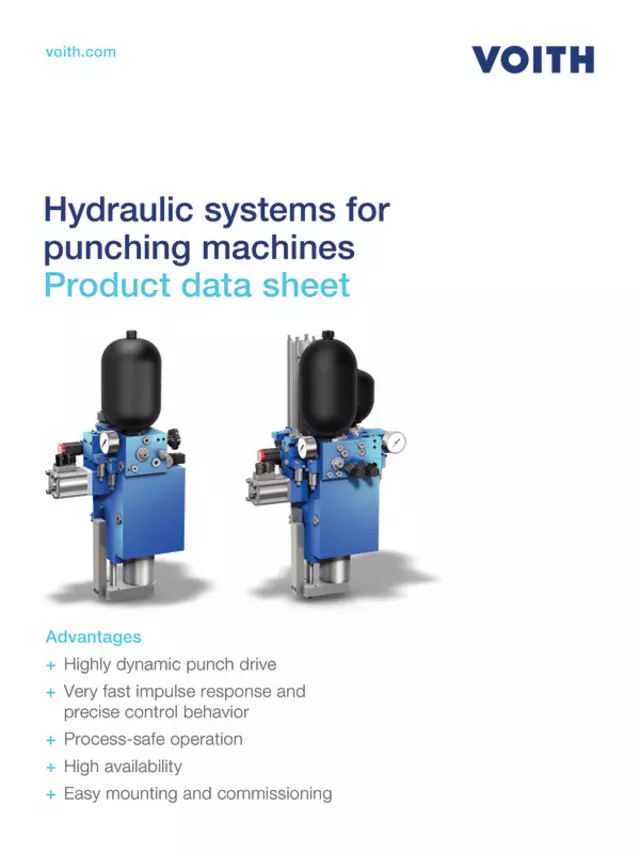

Punching systems

The punching systems HDM and HDE are integrated hydraulic punching systems. They consist of a hydraulic actuator with a directly flanged control block, as well as an application-optimized hydraulic power pack with robust internal gear pumps and an electronic control system.

The punching systems HDM and HDE are integrated hydraulic punching systems. They consist of a hydraulic actuator with a directly flanged control block, as well as an application-optimized hydraulic power pack with robust internal gear pumps and an electronic control system.

Applications

- Punching

- Nibbling

- Forming

Advantages

- Highly dynamic punch drive

- Very fast impulse response and precise control behavior

- Process-safe operation

- High availability

- Easy mounting and commissioning

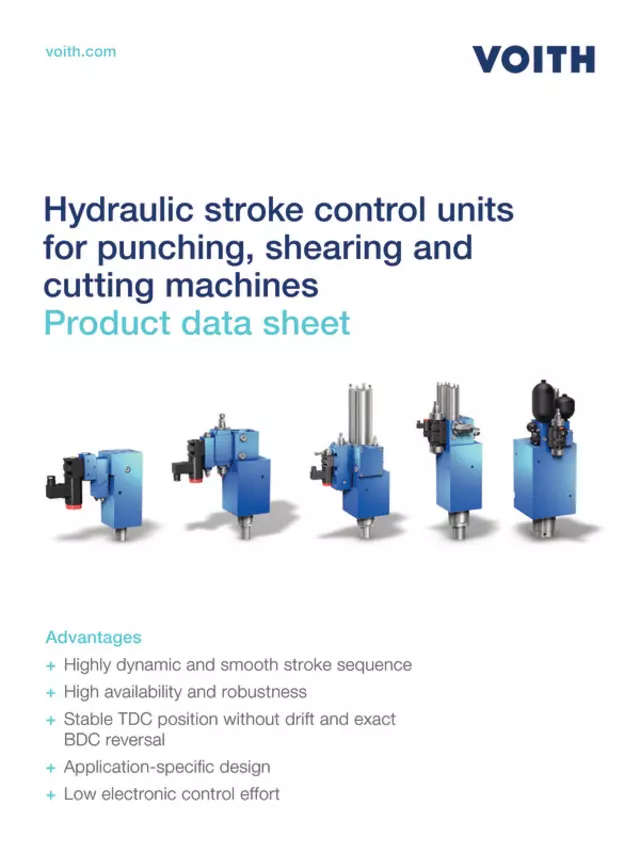

Stroke control units

Voith stroke control units are modular, highly dynamic hydraulic control units. They consist of a hydraulic actuator with directly flange-mounted control block and optionally an application-optimized hydraulic power pack with efficient and robust internal gear pumps and an electronic control system.

Voith stroke control units are modular, highly dynamic hydraulic control units. They consist of a hydraulic actuator with directly flange-mounted control block and optionally an application-optimized hydraulic power pack with efficient and robust internal gear pumps and an electronic control system.

Applications

- Punching

- Shearing

- Cutting

- Stamping/ forming

- Positioning

- Clamping

- Ejection

Advantages

- Highly dynamic and smooth stroke sequence

- High availability and robustness

- Stable TDC position without drift and exact

- BDC reversal

- Application-specific design

- Low electronic control effort

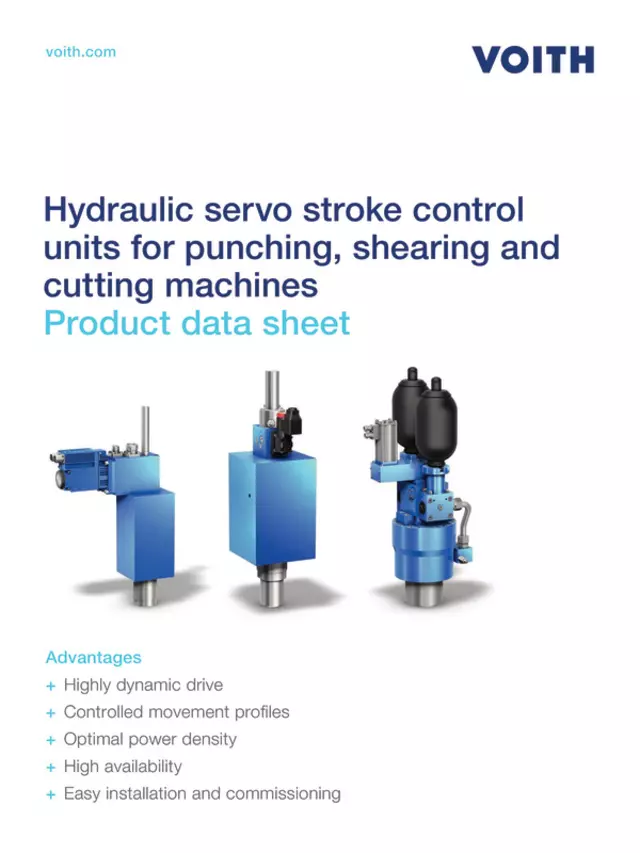

Servo stroke control units

Voith servo stroke control units are modular, highly dynamic hydraulic control units. They consist of a hydraulic actuator with a directly flange-mounted control block with all functions and optionally an application-optimized hydraulic power pack with efficient and robust internal gear pumps and an electronic control system. The actuator is controlled by a servo control valve in a hydromechanical control loop.

Voith servo stroke control units are modular, highly dynamic hydraulic control units. They consist of a hydraulic actuator with a directly flange-mounted control block with all functions and optionally an application-optimized hydraulic power pack with efficient and robust internal gear pumps and an electronic control system. The actuator is controlled by a servo control valve in a hydromechanical control loop.

Applications

- Pre-punching plant/ line punching plant

- Trash hacker

- Ejector

- Machines and plants for stamping, bending, cutting, stamping, shearing and blanking

- Drive for positioning

- Combination drive for punching, shearing and stamping

- Servo drive for forming machines

Advantages

- Highly dynamic drive

- Controlled movement profiles

- Optimal power density

- High availability

- Easy installation and commissioning

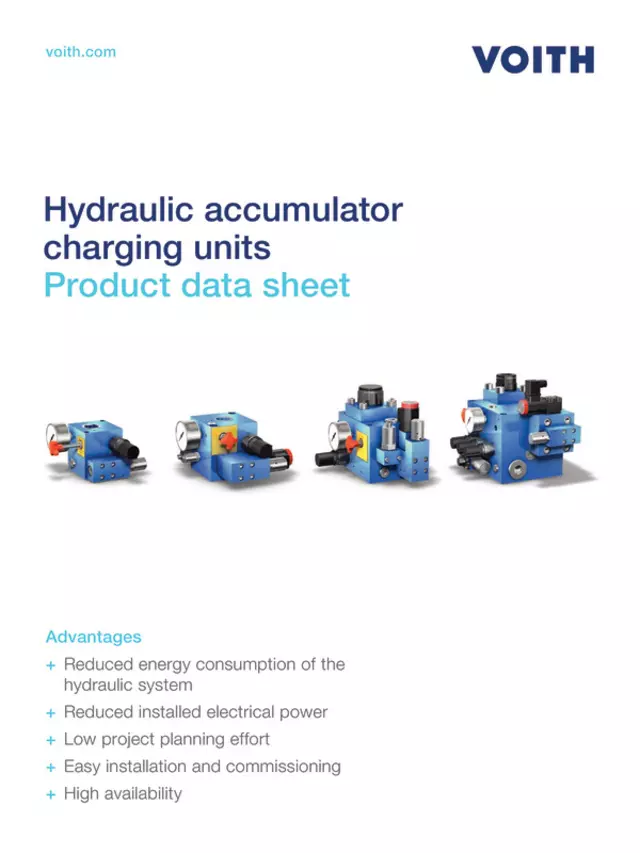

Accumulator charging units

Accumulator charging units are compact functional elements used to control the storage of hydraulic energy in hydraulic accumulators. All functional and safety-relevant components are integrated in the unit. The compact block design reduces the amount of piping required to a minimum.

Accumulator charging units are compact functional elements used to control the storage of hydraulic energy in hydraulic accumulators. All functional and safety-relevant components are integrated in the unit. The compact block design reduces the amount of piping required to a minimum.

Advantages

- Reduced energy consumption of the hydraulic system

- Reduced installed electrical power

- Low project planning effort

- Easy installation and commissioning

- High availability

Roll lifting control units

Hydraulic roll lifting control units are compact and self-contained assemblies for use in roller feeders. Thanks to practical setting parameters, the compact system solution can be adapted to different plant-specific requirement profiles.

Hydraulic roll lifting control units are compact and self-contained assemblies for use in roller feeders. Thanks to practical setting parameters, the compact system solution can be adapted to different plant-specific requirement profiles.

Applications

- Feeding systems

Advantages

- Adjustable lifting stroke without mechanical lift stop

- Adjustable feed roll press force

- Very short, reproducing switch and cycle time

- Service stroke at reduced speed

- Closed function subassembly compact design

- Simple valve control with fast switching valves

Voith Service – how can we help you?

Every day holds new challenges and we help you master them successfully. Anytime. Anywhere. Please click on the icon to find out more about our hydraulic systems services.

Your service helpline

Are you in need of emergency assistance? Call us and we will help you!

t +49 7152 992 3

t +49 7152 992 3