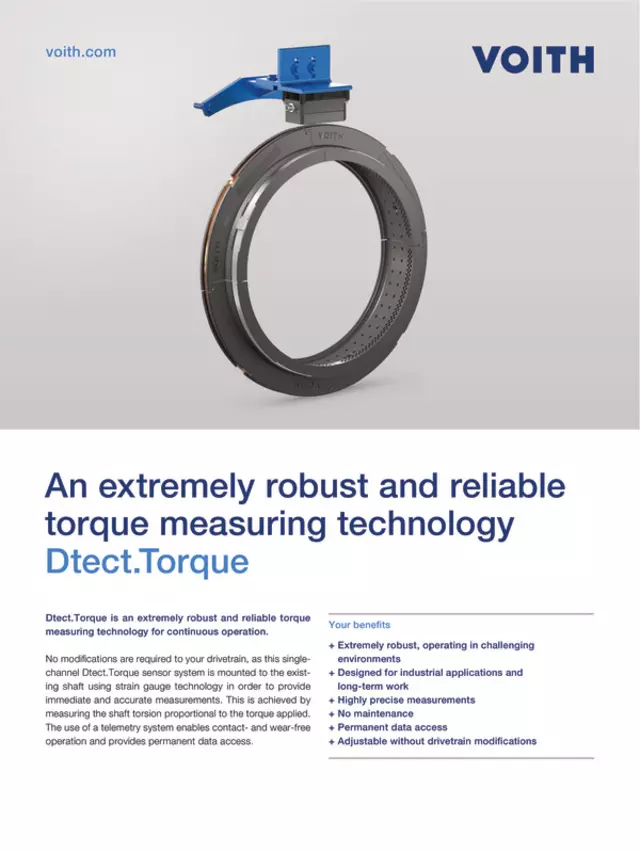

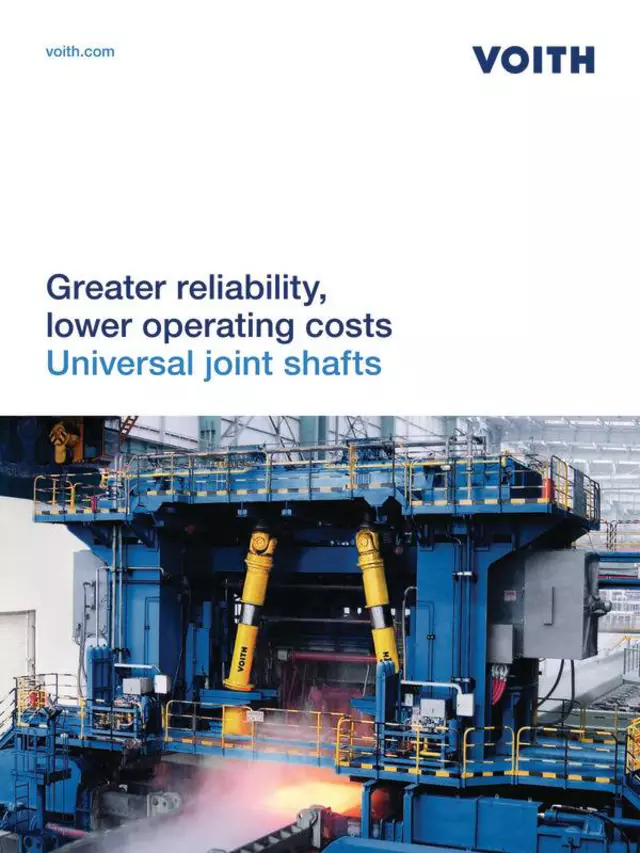

Universal joint shafts

Voith universal joint shafts offer the ideal combination of torque capacity, torsion and bending rigidity. We supply everything from standard universal joint shafts to customer-specific adaptations and custom designs. Our wide range of services includes technical consultation, simulation of torsional vibrations and measurement of operating parameters.

All benefits at a glance

Our product portfolio

Voith universal joint shafts ensure productivity and reduce maintenance costs. The torque capacity extends beyond 20,000 kNm (14 million lbf ft). If necessary, the design layout of our universal joint shafts can be adapted to your drive and operating conditions.

S Series

The S Series is the basic version of Voith universal joint shafts and has been designed for small- to medium-sized drives. The connection flanges are friction flanges. In building the S universal joint shafts, we use high-strength tempered and case-hardened steels that assure the ability to withstand static and dynamic loads. The universal joint shafts have high torque capacity combined with optimal bending and torsion rigidity.

|

Torques with a single load MZ Up to 35 kNm |

Torques with a reversing load MDW Up to 11 kNm |

Centre section Steel |

|

Deflection angle Up to 35° |

Rotation diameter of the joints 52 mm to 204 mm |

Connections Friction flanges |

|

Length compensation

|

||

R Series

These universal joint shafts are of modular design and can be easily integrated into your drives. The flange connections are available in friction and positive locking designs. The R-series have been optimized using FEM. High-strength tempered and case-hardened steels and center sections with a large diameter serve to reduce the weight. At the same time, the bending and torsion rigidity is increased. As a result, the universal joint shaft is highly efficient in operation and less sensitive to vibration stress.

|

Torques with a single load MZ Up to 1000 kNm |

Torques with a reversing load MDW Up to 500 kNm |

Centre section Steel carbon fiber-reinforced polymer (CFRP) |

|

Deflection angle Up to 25° |

Rotation diameter of the joints 198 mm to 550 mm |

Connections

|

|

Length compensation

|

||

CH Series

The CH Series is the standard for high and maximum torques. CH universal joint shafts, connection components and shaft support systems are individually built to specific requirements of your drive system. Flanges and flange yokes are available in a very wide range of designs and materials. We offer you a complete customized drive solution from one single source.

|

Torques with a single load MZ Up to 19,440 kNm |

Torques with a reversing load MDW Up to 11,910 kNm |

Centre section Steel carbon fiber-reinforced polymer (CFRP) |

|

Deflection angle Up to 15° |

Rotation diameter of the joints 350 mm to 1,400 mm |

Connections

|

|

Length compensation

|

||

E Series

The E Series joints have the greatest torque capacity in comparison with the other series – it transmits a torque up to 20% greater than a CH universal joint shaft with the same joint diameter and features increased bearing life. The E Series universal joint shaft can be equipped with an E joint at both ends or one E joint can be combined with a CH joint. It is ideal if installation space is limited.

The E Series, connection components and shaft support systems are individually built to specific requirements of your drive system. Flanges and flange yokes are available in a very wide range of designs and materials. We offer you a complete customized drive solution from one single source.

|

Torques with a single load MZ Up to 13,620 kNm |

Torques with a reversing load MDW Up to 9,380 kNm |

Centre section Steel carbon fiber-reinforced polymer (CFRP) |

|

Deflection angle Up to 10° |

Rotation diameter of the joints 580 mm to 1,220 mm |

Connections

|

|

Length compensation

|

||

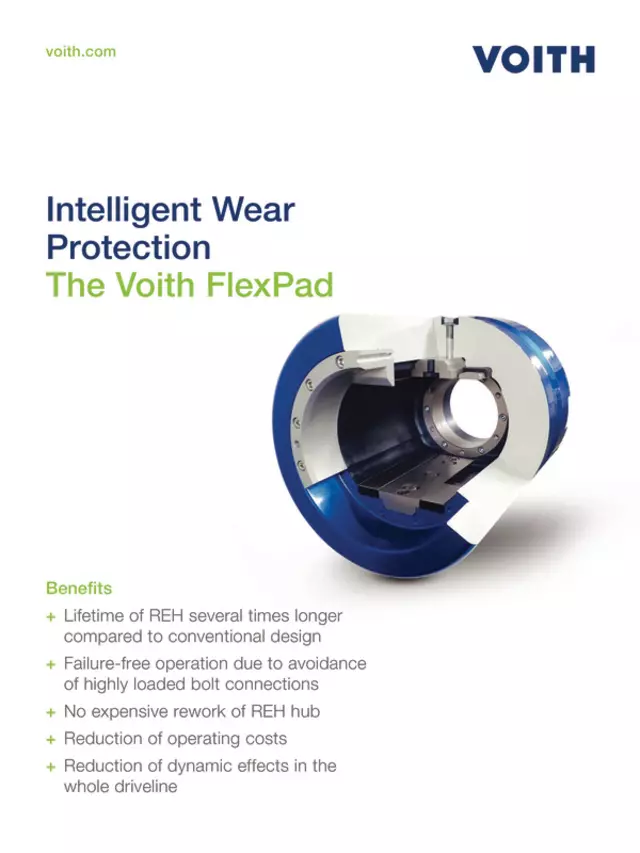

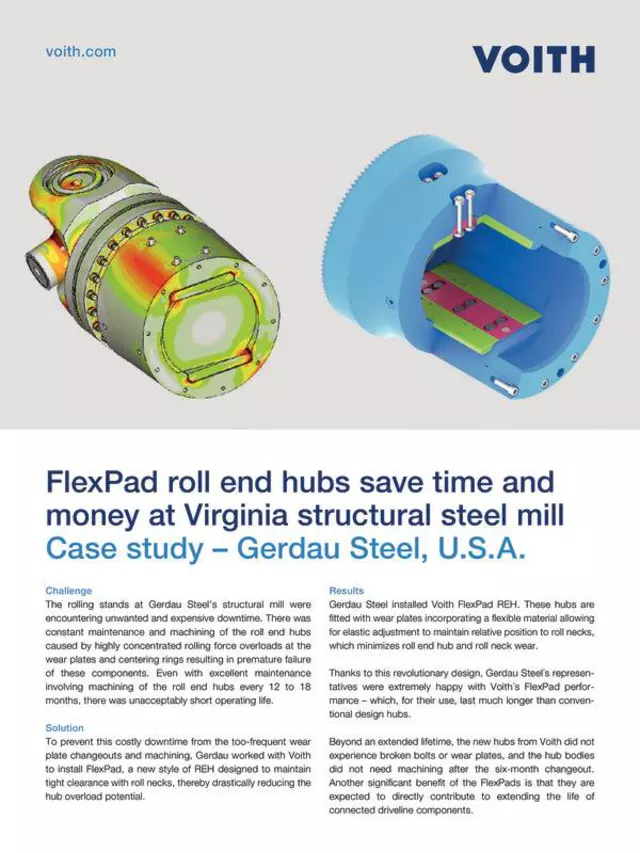

Voith FlexPad

The Voith FlexPad Roll End Hub (REH) design greatly increases hub body operational life through a significant reduction in wear

OnCare.Health Universal Joint Shafts

The torque signals are analyzed in real time and processed to provide characteristic values for the specific universal joint shaft. Using intelligent algorithms, the service life of the cardan shaft bearings and joints is calculated, allowing you to more effectively plan when to replace or procure individual system components.

Voith Service – how can we help you?

- Everything from a single source: development, design, production – and service!

- Decades of product experience as an original equipment manufacturer and service provider

- Fast and smooth cooperation and best service thanks to a worldwide network of service locations

- Long-term partnership and planning security are guaranteed due to longstanding corporate stability