CleanLine

The complete solution for fabric cleaning

Innovative cleaning systems for every paper machine section

As a leading supplier of world-class paper machines, it is part of our business to deliver top-performing cleaning systems. Voith’s CleanLine offers a complete range of cleaning systems to cover every section of your paper machine.

Paper machine fabrics run in a harsh production environment, yet they are critical to process. Continuous fabric performance and optimal productivity are significantly improved with CleanLine traversing cleaning systems. CleanLine is a comprehensive range of fabric cleaners that meets the challenging demands and conditions across the entire paper machine.

The right cleaner for every section

| Former | Press | Dryer | Coater | |

|---|---|---|---|---|

|

Uniform cleaning |

x | x | ||

|

Improved cleaning and waste water removal |

x | |||

|

Continuous online cleaning |

x |

How can we help you? Talk to your personal expert:

CleanLine product range

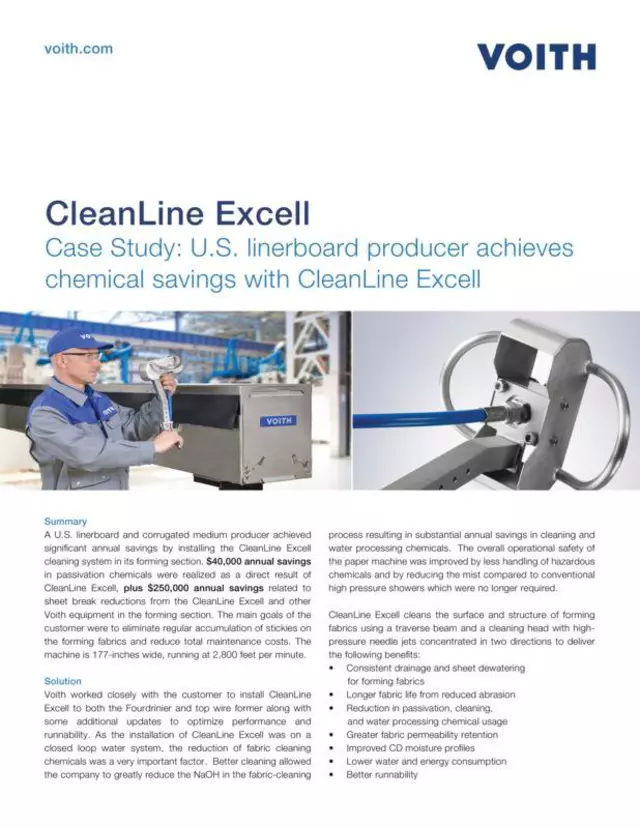

CleanLine Excell – for forming fabrics and press felts

Consistent and uniform cleaning

High fiber retention and uniform dewatering are key factors of performance in the forming and press sections of your paper machine. CleanLine Excell cleans the surface and structure of forming and press fabrics more effectively than oscillating high pressure needle jet showers or standard traversing showers. The CleanLine Excell cleaning system uses less water than high pressure showers, significantly reduces chemical cleaning, and is even suitable for fine fabric surfaces.

Your benefits

- Improved drainage and sheet dewatering for forming and press fabrics

- Uses less cleaning chemicals

- Greater fabric permeability retention

- Better uniformity

- Less water and energy consumption

- Better runnability

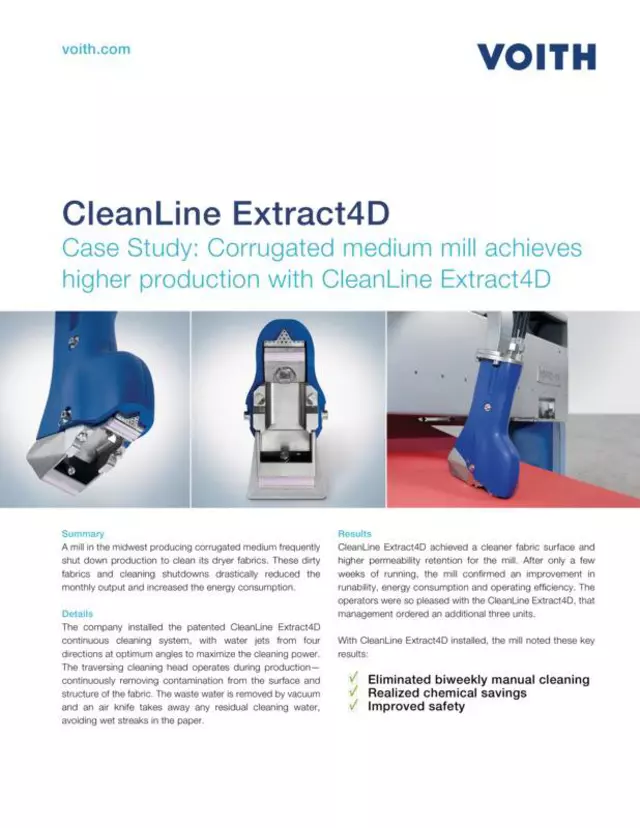

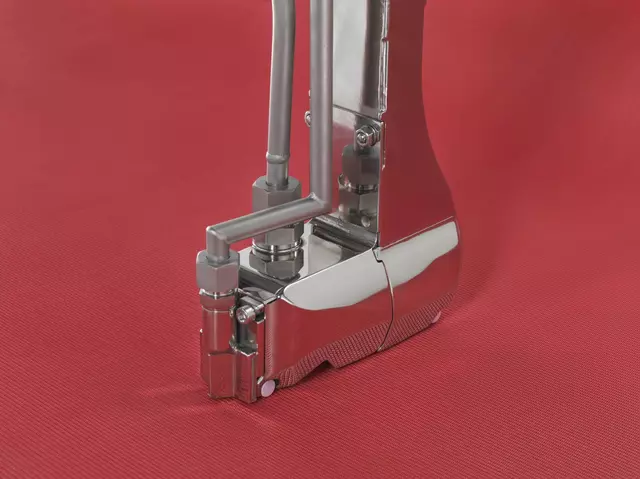

CleanLine Extract360 – for dryer fabric cleaning

Improved cleaning and waste water removal

Contamination in the dryer section reduces productivity by affecting drying efficiency and runnability. Fabric permeability is reduced by contamination on the fabric surface, at the crossover points between the yarns, and within the voids of the structure. Conventional cleaning systems with water jets in one direction only contact a fraction of these contaminants. CleanLine Extract360, with water jets in five directions, overcomes the limitations of conventional cleaning systems. With flow-optimized fluid channels, the cleaning effect as well as the waste water removal is brought to another level.

Your benefits

- Improved retention of fabric permeability

- Increased drying efficiency

- Better sheet stability and tail threading

- Uses less cleaning chemicals

- Optimized sheet quality

- Improved cleanliness of dryer section (guide rolls, walkways, machine framing)

CleanLine Extreme – for tensioning fabrics after coater

Continuous online cleaning for

high-quality coated paper

Achieving a high-quality surface on coated papers requires the fabrics after coater sections to be free of contaminants. Stripes from blade failure, contamination from breaks, and contamination stripes at the paper edges are concerns that impact both production efficiency and paper quality. Often it is only possible to carry out manual or offline shock cleaning of the fabrics after a sheet break or during shutdowns. This means that in between cleaning, spots of coating can run on the fabric surface. The solution is CleanLine Extreme, which cleans both online and offline to provide additional benefits for papermakers.

Your benefits

- Cleans consistently both online and offline

- Yields the highest quality coated paper

- Improved fabric performance

- Safe operation and reduced manual handling

- Easy maintenance

Publications

Engineered for success

-

-

-

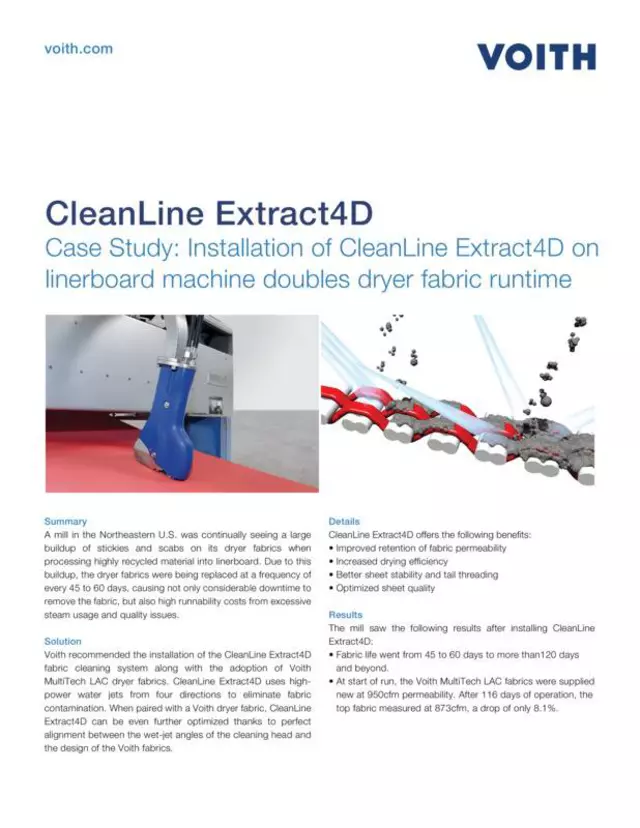

Case Study: Installation of CleanLine Extract4D on linerboard machine doubles dryer fabric runtime

PDFEnglish

Our Service for CleanLine – Part of Your Business

Get the most out of your fabrics

We can help you to optimize your equipment mechanically and to maximize its process performance in an effective way. All of our fabric cleaner services are available for the CleanLine as well as the DuoCleaner product families.

A lifetime of cleanliness

With over 30 years of experience and more than 1.000 installations globally, Voith is the reliable partner for fabric cleaning solutions. Please contact your sales manager to discuss how the fabric cleanliness on your paper machine can be improved. All details regarding our CleanLine Service can be found in the product sheet:

- Ensure equipment availability, reliability and safety

- Increase runability and productivity of your paper machine

- 100 % professional OEM services and parts

- Minimize your maintenance efforts and increase your efficiency

Check out our complete service portfolio

Our service for the paper industry ranges from individual equipment service to maintenance partnerships. Together we will find the right offer for you.

With AdvancedPRODUCTS, we offer smart product combinations that work in perfect harmony with one another. Higher added value is achieved through individually matched product combinations that maximize the performance of your paper machine.

For example, the effects of contamination are significantly reduced in the dryer section with CleanLine Extract4D, CleanWeave dryer fabrics, ProRelease+ web stabilizer, and TerraDry roll covers. Together, these solutions elevate the overall performance of your machine to lower operating costs, increase productivity, improve paper quality and ensure employee safety.