Edge components

Increase edge stability and profit from uniform paper quality

Voith offers several components for efficient edge control on wires in top formers and Fourdrinier formers. For each application, a well-proven solution is available to improve machine runability and basis weight cross profile quality.

Product portfolio

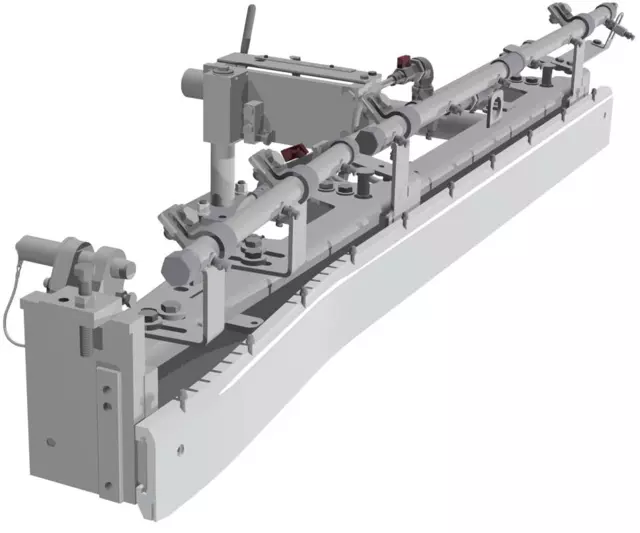

EdgeSaver

Save costs and increase edge stability

The unique EdgeSaver edge trimming concept makes it possible to separate the web edge already in the exiting headbox jet. This not only saves valuable raw materials such as virgin fibers, but also reduces the energy requirements of your paper production.

Discover the blade of our new EdgeSaver:

With conventional systems, edge trimming on multi-ply machines takes place only after couching, so that the resulting mixed trim residues can only be returned to the circuit of lower quality.

In contrast, the innovative design of the EdgeSaver blade, provides a simple and energy-efficient solution to adjust the web edge directly in the headbox jet. Fibers in excess of the required web width are not lost in the couch pit, as they are discharged before the suspension hits the wire. The discharged stock suspension can thus be returned directly to the primary fiber stock circuit in a single-sort process.

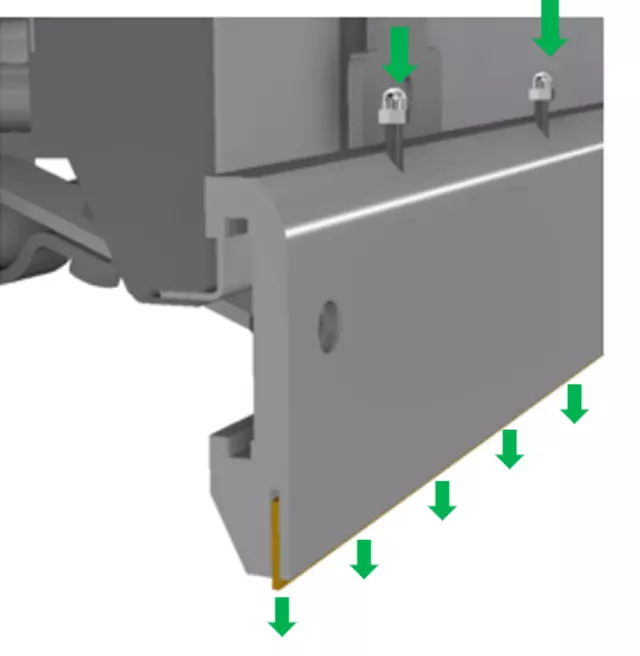

Thanks to the specially manufactured side shield, with adjustable „S“-shaped offset, the EdgeSaver enables edge waves to be minimized, thus improving edge stability. The teflon seal on the underside of the side shield provides an optimal seal to the forming fabric.

Changing the wire is also no hurdle: The clever swiveling device enables convenient replacement of the forming fabric without having to restore the optimized settings on the EdgeSaver afterwards.

Would you like to know how this works? You can find all the details in the product sheet:

Your benefits:

- Significant savings on high quality pulp grades

- No high pressure or fresh water required for separation

- Flexible and easy adjustment of headbox jet width

- Fast return on investment of only a few months

- Suitable for headboxes of all manufacturers

- Service position for quick wire changes and maintenance

- Adjustable while the machine is running

This means, we not only produce more sustainably, but also more cost-efficiently. In addition, we are convinced by the EdgeSaver's ease of use as well as its reliable operation throughout.

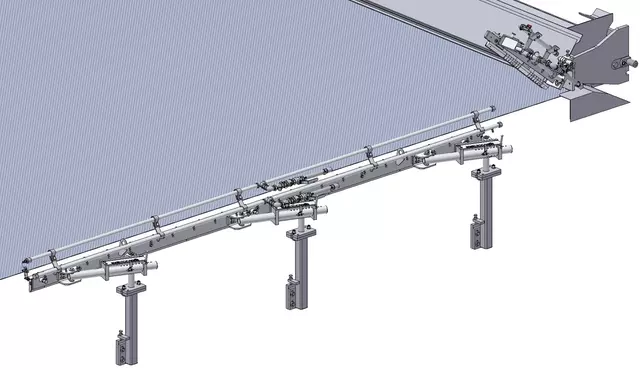

EdgeMaster

Edge control for optimal paper web edge

EdgeMaster is a variably adjustable extension of the headbox format plate. In the Fourdrinier wire and the hybrid former, it provides for uniform distribution of the stock suspension up to the edge.

By setting the position of the EdgeMaster in machine direction, it can be optimally adapted to the shape of the flow. Positioning screws allow precise lifting, lowering and pivoting. Water flushing prevents the suspension from flowing under the edge control device. In addition, spray water nozzles continuously moisten the surfaces in contact with the stock, enabling trouble-free production.

The EdgeMaster is retrofitted with an adapter plate extension to the existing headbox or by supplying a new format plate.

EdgeMaster is used at headboxes for Fourdrinier wire and hybrid former paper machines. These devices are frequently combined with wire edge lifters (EdgeCurlers).

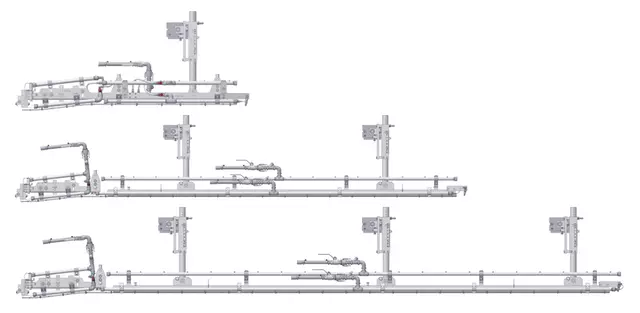

EdgeDeckle-S

Next generation of Edge Components

The EdgeDeckle-S is a new design of edge guiding system for the Fourdrinier wire section.

Unlike than common edge deckles with EdgeDeckle-S it is possible to influence actively the flow condition at the web edges by the adjustable side shield geometry.

That makes the EdgeDeckle-S to a tool for the papermaker to eliminate the edge wave effect in the papermaking process.

Adjustment and optimization can be done without tools, even during production. There is no need for time consuming readjustments during grade change.

For large slice openings an extension of the edge deckle plate is used.

The side shield extension is designed according to production data of the PM.

For easy service purposes or during wire change, the EdgeDeckle S can be swiveled into the maintenance position and fixed.

Disassembly of the equipment for wire change is not necessary. There is no need for sensitive sealing gap adjustment after wire change.

The sealing strip setup requires no tools and can be done even on running PM.

The innovative sealing concept in addition to the user-friendly adjustment possibility guarantees easy handling during production and maintenance.

Your contact - How can we help you?

Servolution. Service at the next level

At Voith, service means taking care of issues that matter to our customers and utilizing our full expertise to help them reach their goals.