DuoShake DG

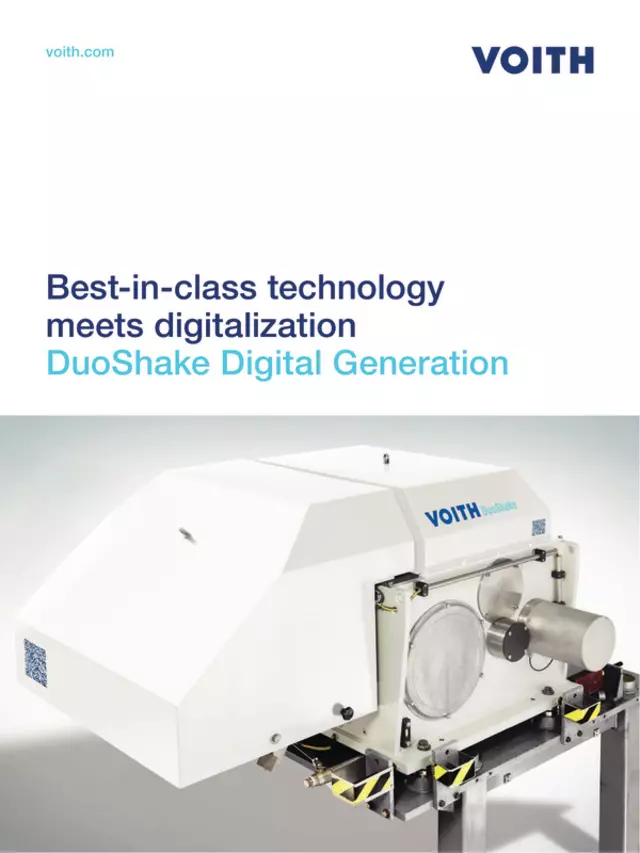

Best-in-class technology meets digitalization

Maximum process reliability and machine availability

DuoShake is a reliable shaking unit that has been established on the market for decades. Thanks to the clever utilization of forces, it makes an indispensable contribution to high-quality paper production. With its new product DuoShake DG (Digital Generation), Voith, in its capacity as technology leader and innovation driver, is taking the next step on its journey to Papermaking 4.0. A comprehensive, exceptionally user-friendly update of control and automation functions significantly improves process reliability and machine availability while lowering operating and maintenance costs. As a result, DuoShake DG has been equipped for the paper production of the future.

If you have any questions contact us now!

How you benefit from our shaking unit

Excellent formation through high-frequency shaking

Sheet formation in the forming section has a considerable influence on paper quality and downstream processing. The system optimizes fiber orientation through high-frequency shaking of the breast roll. The result is excellent formation of all paper grades and a low tensile strength ratio.

High paper quality

The DuoShake DG shaking unit for the breast roll contributes to a more homogeneous distribution of fibers and an increased orientation of the fibers in cross direction. Paper quality is increased due to improved formation in Fourdrinier paper machines. This results in benefits for the downstream processing, coating, impregnating and printing of the paper.

Perfect physics

Two rotating pairs of imbalance masses are arranged on the hydrostatically mounted carriage of DuoShake DG. The rotation causes forces to develop that are transferred to the breast roll with a shaking rod. Compared with conventional shaking units, the system, which oscillates freely in horizontal direction, only transfers negligibly small friction and centering forces to the base. The base only has to support the dead weight of DuoShake DG; no disruptive reaction forces are transferred to the headbox or wire section.

Operating parameter changes during operation

In the event of changes to production conditions or a grade change, new values can be input at any time direct at the paper machine. DuoShake DG allows the infinitely variable adjustment of shake stroke and frequency during operation of the paper machine. There is no mechanical stroke adjustment.

Installation sizes to meet requirements

DuoShake DG is available in two different sizes with 250 Nm and 800 Nm drive motors. The size required can be roughly determined based on the operating characteristics. A dimension sheet can be used on site to check whether the space available at the paper mill is sufficient for the installation size selected. The dimension sheet is contained in the brochure.

Increase efficiency

Paper producers can reduce fiber consumption by using DuoShake DG. Further savings relate to the use of strengthening agents (chemicals). Overall the system is very robust, and the hydrostatically mounted carriage is low-wear, which results in a very high reliability.

The new features of DuoShake DG

Designed for optimum operability and the future of paper production, DuoShake DG enhances the physical production process by exploiting the options offered by digitalization and the use of smart data. The product update has a lot of new features such as real-time data monitoring, including remote monitoring via mobile devices, condition-based maintenance, trend analyses and a cloud connection. Find out more in the following video:

Digital transformation is starting in industry, too, with an analysis of the current situation: Just how much digitalization is there in my company? What tools and processes are already digital or urgently need to be redesigned to meet the demands of cloud-readiness or IIoT-readiness? Which products and services can be digitally upgraded or streamlined at little cost? How secure are the assets in OT (operational technology) and IT? Which sequences need more attention, more resources and additional personnel?

Engineered for success

DuoShake DG case study

A paper mill in the South Central United States that produces liner board wanted to improve its product quality and production parameters, including sheet formation, appearance and strength — all while maximizing its machine speed. Read in the PDF how this works:

-

Case Study: Paper mill improves sheet formation, increases machine speed with DuoShake DG

PDFEnglish

DuoShake DG case study II

A west coast paper mill in the United States that produces recycled linerboard wanted to optimize the sheet strength and basis weight of their product to increase MSF yield per ton — all while maximizing its machine speed. Find all details in the PDF:

-

Case Study: Paper mill improves sheet strength and optimizes basis weight, increasing MSF yield per ton

PDFEnglish

See how the shaking unit works

Step by step explanation

In the video you will see the challenges confronting paper producers during the stock distribution process, as well as the precise functioning and technical background of DuoShake.

FloatBearing – minimal friction during the shaking process

Ideal addition to DuoShake DG

The newly developed FloatBearing is the ideal solution for making optimum use of the performance of the DuoShake DG. The hydrodynamic bearing reduces the friction between the metal surfaces of a shaking unit even at low machine speeds.

Minimized wear

The use of the FloatBearing eliminates the inherent disadvantages of cylindrical roller slide bearings. With the hydrodynamic principle, the rotating journal conveys oil into the convergent bearing clearance. The oil pressure building up there lifts the journal from the bearing bushing. This ensures a complete separation of the metal surfaces by the oil. The shaking unit can be operated and the bearing works in a no-wear manner.

Excellent operational reliability

Thanks to its compact design, an upgrade to the FloatBearing involves only a small rebuild outlay. The enclosed design, integrated cooling grooves and optimized seal with labyrinths and protective hoods provide for a high level of operational reliability.

Patented emergency lubrication system

Even in the case of a short-term stoppage of the oil hydraulic system and associated stoppage of the bearing’s oil supply, limited further operation of the bearing without damage is ensured by a specifically developed and patented emergency lubrication system.

Find your local expert

Our Service for DuoShake – Part of Your Business

Maintain best formation

The DuoShake breast roll shaking unit contributes to a more homogeneous distribution of fibers and an increased orientation of the fibers in cross direction. The result is a better formation and a lower MD/CD tensile strength ratio, so that an overall higher level of quality will be achieved. Safeguarding this level is the longterm goal of Voith DuoShake Service.

The key to perfect formation

Our globally active Voith service specialists have the right skills and long-term experience with over 300 DuoShake installations. The link of our DuoShake via Cloud connection to our remote service center OnPerformance.Lab helps in using digitalization profitably. We are happy to combine any services from our comprehensive Servolution portfolio to an attractive service agreement. All details regarding our DuoShake service can be found in the product sheet:

- Maintain the highest level of formation and CD strength values

- Maximum equipment availability, reliability and safety

- 100% professional OEM services and parts

- Cloud connection allows additional service options

- Improved performance while minimizing maintenance efforts

Check out our complete service portfolio

Our service for the paper industry ranges from individual equipment service to maintenance partnerships. Together we will find the right offer for you.

As a full-line supplier, Voith is a byword for customized, demand-driven service solutions. Voith products and services are perfectly tailored to one another. This means that paper producers benefit from the comprehensive expertise of Voith specialists to consistently meet their production targets in a way that is cost-efficient and sustainable.

Order products and services from Voith quickly and easily around the clock via the Voith Paper Webshop. Optimize your purchasing processes and get to know many other helpful features.