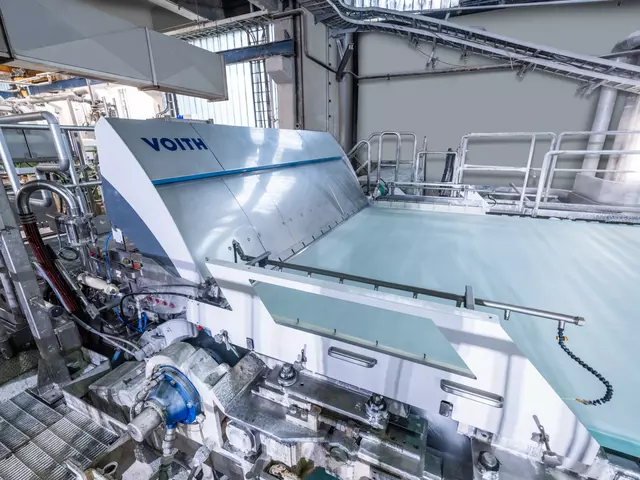

MasterJet 4Tec

Perfect headbox technology for every application

The MasterJet 4Tec marks the fourth generation of MasterJet headboxes from Voith Paper. This new model offers significant advantages in four key areas: formation, pulsation damping, ease of operation and energy efficiency.

Compared to its predecessor, the already powerful MasterJet Pro, the MasterJet 4Tec offers significantly improved headbox jet quality. This is the ideal prerequisite for very good formation values, no streaks and therefore perfect paper properties.

Another highlight of the MasterJet 4Tec is the newly developed pulsation damper. It has a flexible membrane that separates the air volume from the pulp suspension, ensuring maximum cleanliness and stable machine operation. In addition, the damper does not generate any pressure loss, which reduces the energy consumption of the headbox pump.

Other innovations such as the new EdgeMaster significantly improve cleanliness and ease of use. The MasterJet 4Tec therefore represents a significant advancement in headbox technology.

Your benefits with MasterJet 4Tec

- Highest paper quality

- Better cross profiles of grammage and fiber orientation

- Lower operating costs

- Fast and trouble-free grade changes

- Comfortable operation and maintenance

- Highest availability

Add-ons improve your headbox performance

EdgeModule – Edge feeding for improved fiber orientation

Fewer edge breaks through improved edge stability

EdgeModule provides separate feeding of the outer turbulence generator columns on the front side and drive side in order to influence the nozzle flow and finally the fiber orientation cross direction (CD) profile. The suspension is controlled by means of the integrated flowmeter and ball valve.

EdgeModule thereby contributes to a considerable improvement of paper edge stability and fewer edge breaks.

MasterJet 4Tec for decor papers

Unique concept for special requirements

Especially for the production of specialty papers, the homogeneity of the stock flow is of the utmost importance and the basis for optimum profile quality, uniform sheet formation and the prevention of streaks.

To meet these challenging requirements, Voith worked with the Felix Schoeller Group to completely optimize its headbox hydraulic system, focusing primarily on the turbulence generator, the lamellas and the headbox nozzle. In comprehensive pilot trials and simulations, these components were improved and perfectly matched with one another. With the new MasterJet Pro, the Felix Schoeller Group has achieved a significant improvement in the quality of its decor paper.

Engineered for success

Successful headbox rebuild at BM 3 improves quality and productivity

Not only did the close collaboration between the two companies deliver a three percent increase in productivity and an improvement in paper quality; extending the dewatering section with an improvement in dewatering capacity also proved to be an expedient measure. Production could restart ahead of schedule thanks to the well-coordinated collaboration between all parties during the planning and rebuild phases.