FilmLube

FilmLubeIntegrated Uhle box lubrication

Uniform felt conditioning with FilmLube

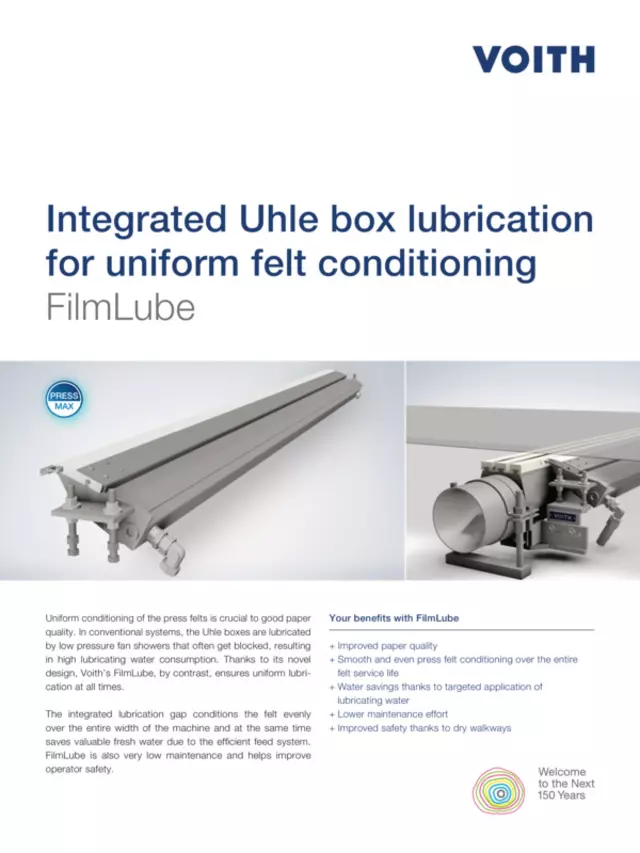

Thanks to its novel design, FilmLube ensures uniform lubrication at all times. This results in a more uniform moisture cross profile, improved paper quality and lower water consumption.

In conventional systems, the Uhle boxes are lubricated by low pressure fan showers that often get blocked. FilmLube, in contrast, is equipped with an integrated lubrication gap directly in front of the Uhle box which ensures optimum application of water over the entire width of the machine. The efficient feed system saves valuable fresh water and improves safety thanks to dry walkways.

Your benefits

- Improved paper quality

- Smooth and even press felt conditioning over the entire felt service life

- Water savings thanks to targeted application of lubricating water

- Lower maintenance effort

- Improved safety thanks to dry walkways

-

Integrated Uhle box lubrication for uniform felt conditioning. FilmLube

PDFEnglish German Portuguese

Operating principle

Comparison between conventional lubrication and FilmLube

Uhle box lubrication

1 - Lateral losses due to incorrectly adjusted nozzles

2 - Spray mist losses

3 - Partially blocked nozzle with drifting spray fans

4 - Completely blocked nozzle

5 - Even film of spray water

! - Areas of potential felt damage

CD moisture profile [g/m2]

FilmLube - How can we help you?

India

Abhijan Chakraborty

Associate Manager, Application Engineer - PM Rebuilds

t +91 33 23005578 Send an email

Servolution. Service at the next level

At Voith, service means taking care of issues that matter to our customers and utilizing our full expertise to help them reach their goals.