Performance increasing upgrade solutions for suction rolls

Enhancing suction roll performance with AR technology: TrackLight AR

Suction zones and seal strips are typically inaccessible within the suction roll. With TrackLight AR, it is possible to have a virtual window into the roll, enabling real-time monitoring of both the suction zone and the edge deckle position. This technology ensures consistent settings and minimizes downtime for suction roll maintenance.

Optimum adjustment is the biggest challenge and requires a high level of expertise, because you can’t look inside the suction roll. Suction zones are restricted through sealing strips and edge deckles. Both are not visible and only identified through markings on tender side. The suction roll shell covers the suction box, so sealing strips are also not visible.

Augmented Reality (AR) has emerged as a groundbreaking technology that combines the digital and physical worlds to enhance our perception and interaction with reality.

At its core, AR supplements our physical surroundings with digital content, seamlessly blending virtual objects and information into our real environment.

Voith uses this technology to enable papermakers to access relevant but invisible elements to inspect and adjust their suction rolls.

Advantages

- Support customers to retain the knowledge of experienced senior papermakers

- Improved energy efficiency, maximized dewatering and better runnability of suction rolls

- Reliable real-time adjustment of suction box for best dryness

- Reduces time required for adjusting suction box and edge deckles

- Easy visual identificarion of current suction box and edge deckle position

- Quality diagnostic tool or suction zone issue root cause

Wear detection for all suction rolls: SealView

How can we help you?

Total utilization of the seal strip capacity due to exact wear detection.

The reliable SealView technology, which can be used with conventional and HydroSeal seal strips, records the wear progress of each individual seal strip. The system informs the operator and our service staff about the current status and the expected remaining service life of the seal strip and draws their attention to a necessary roll change in time.

The system is based on a non-electrical system, which makes it highly reliable. Once SealView is completely installed in a suction roll during roll servicing and put into operation by our service staff at the operator's site, the wear of each individual strip can be visualized on a monitor in the control room.

The system warns the operator when half of the seal strip service life is reached. If a safety reserve is reached before the end of the complete wear area, an alarm is triggered. With this information, the operator has enough time to plan a stress-free removal of the roll and to coordinate further steps of the roll service as well as the procurement of replacement strips with the Voith Service Center.

The system reveals its full potential especially when roll running times are extended beyond the usual period of time. By displaying the wear of the seal strips, the operator knows that he is safe even with extended operating times, without the worry of an unplanned standstill.

Benefits

- Total utilization of the seal strip capacity

- Longer running time of the suction rolls

- No unscheduled shutdowns

- Planning time for spare parts procurement

The seal strip for all suction rolls: HydroSeal

How can we help you?

Excellent savings in lubrication water consumption

HydroSeal is the first to provide the option of dispensing with the conventional lubricating shower regardless of the type of suction roll or manufacturer.

Thanks to HydroSeal, the lubricating water is distributed continuously over the entire width of the seal strip, which allows the surface to be continuously covered with a homogeneous film of lubricating water. The efficient feed substantially reduces the amount of lubricating water required. Moreover, this new design prevents remoistening of the paper web and also improves the CD moisture profile.

Trials carried out in the field on our customers' machines demonstrated that, by using HydroSeal, lubricating water consumption could be reduced by up to 87%. Specific energy consumption was cut by 9%. This means that even on just one suction roll, HydroSeal can achieve savings of 100,000 euros or more per year, offering a distinct economic benefit as well as an ecological advantage.

Contact your expert

References

Voith's HydroSeal significantly

reduces mill’s resource usage

A tissue mill in the Southern U.S. was looking for opportunities to save on production costs and asked Voith to make a proposal to achieve those savings.

Optimize your production process with HydroSeal

Watch this video comparing the conventional lubrication system with HydroSeal and convince yourself of this ecologically sensible system.

Services for HydroSeal - Part of your business

We are the experts for the entire system

In the course of a standard roll service, the delivery of HydroSeal includes the tubing internal to the roll, the water distributor, all required hose feed lines and a filter station, as well as comprehensive on-site support at the first startup. If necessary, a new set of seal strip holders is installed during replacement of the HydroSeal seal strips.

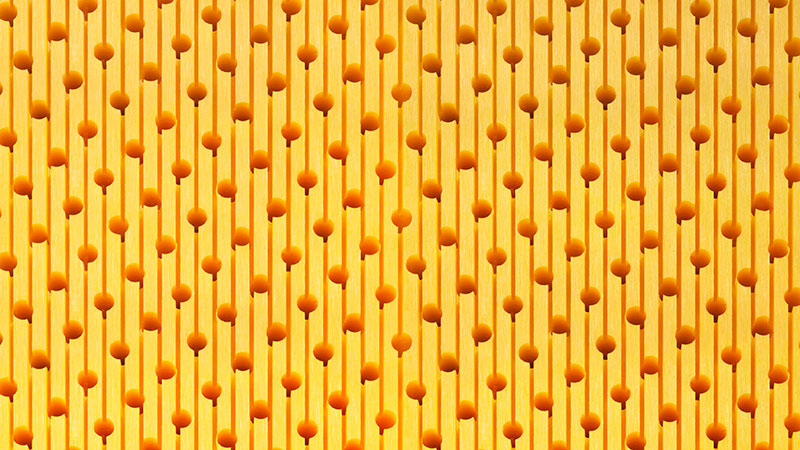

NipMaster analysis program for optimum dewatering

Designed for efficiency

The NipMaster concept exploits the surface design of suction and press rolls and comprehensively analyzes optimum dewatering characteristics.