Enter the digital future of rail freight

The digital automatic coupler (DAC) is set to revolutionize rail freight with automatic connection and disconnection of air pipes, data lines, and power lines. Its futuristic functions promise to make rail freight much faster, safer, and more efficient, all while contributing to the reduced emissions targeted by the European Green Deal. Simply put, the DAC sets an entirely new benchmark that is essential to the future success of rail freight systems.

Benefits of the DAC

Offering a stable data link via its integrated e-coupler, Voith’s CargoFlex powers full-scale freight digitization. With a team of uniquely experienced experts and a range of tailored services, Voith is here to help take your rail freight operations to the next level.

Higher safety

Time savings

Cost reduction

Flexible customer solutions

Automation

Future-oriented technologies

Your guide to the DAC revolution: goodbye manual coupling, hello digitization and automation! Find out what this means for freight operators everywhere.

Technical specifications

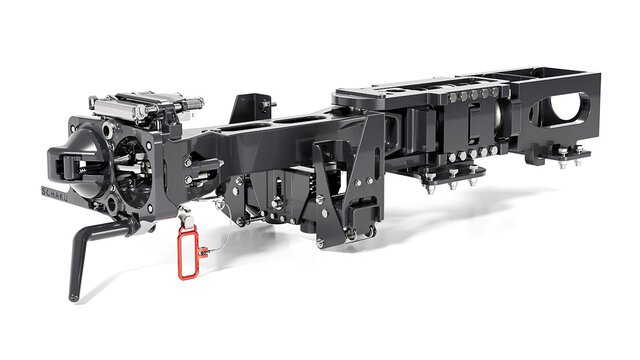

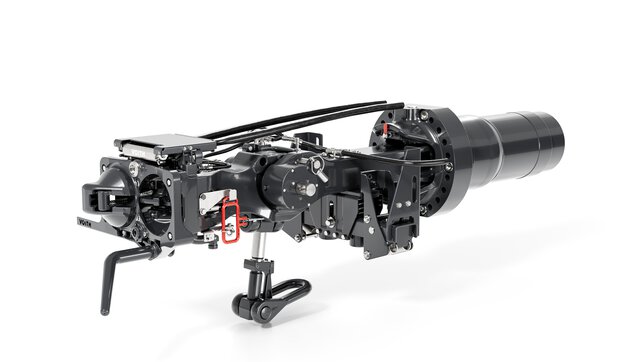

The CargoFlex not only enables automation but also additionally forms the basis for diverse digital functions through an integrated electric head. With its automatic head that can be swiveled up, the CargoFlex Hybrid for locomotives allows successive conversion, because in addition to automatic coupling, Connection with UlC drawhooks is also possible.

Product Information:

- Automatic Scharfenberg coupler for freight cars

- Can be extended with various modules

- No intervention in car structure

- Tensile and impact energy absorption

- Power and data transmission possible

Special characteristics:

- Suitable for UIC-compliant Installation spaces

- Weight-neutral system in comparison with screw coupler + buffer

Application area:

- Freight cars

Product Information:

- Automatic Scharfenberg coupler for locomotives

- Head that can be swiveled up for additional coupling to a drawhook

- Can be extended with various modules

- No intervention in car structure

- Tensile and impact energy absorption

- Power and data transmission possible

Special characteristics:

- Swivel device on automatic head enables coupling with a drawhook

Application area:

- Locomotives

Product Information:

- Mechanical coupling, plus automatic coupling of e-coupler for data transfer

- Train composition: wagon length and position detection at all times

- Automatic brake test shortens time-consuming pre-departure process

- Mechanical uncoupling for greater safety of staff

- Electrical uncoupling triggered from comfort of driver’s cab

* The couplers are constantly being further developed and improved in close cooperation with operators.

Unrivaled real-world experience

The CargoFlex has already been in regular service for over half a decade. Unmatched by any other solution, these years of experience stem from Voith’s pioneering partnership with leading Swiss freight transporter SBB Cargo.

2019 saw the launch of this pioneering partnership.

Having installed Voith’s CargoFlex on 200-plus freight wagons and 25 locomotives, SBB Cargo now plans to add it to all intermodal combined freight trains – and enjoys 50% faster formation.

Both partners are also part of the DAC+ consortium that intensively tests the digital functionalities of the DAC on a dedicated pilot train equipped with CargoFlex.

CargoFlex freight couplers

With the DAC, operators will have completely new options for improving the efficiency of transport operations.

Freight cars

Head start with retrofitting: Voith Turbo is already preparing freight cars

Voith Turbo is already offering freight car operators a simple, risk-free way to break into the world of the automatic coupler. By modifying the cars to make them “DAC-ready”, the company is equipping existing freight cars with the CargoFlex energy absorption system. This “draw gear unit” is located in the freight car’s standardized UIC-530-1 installation space, while draw hook and buffers remain on the vehicle. In a second step, these will be dismantled simultaneously throughout Europe and the front part of the CargoFlex coupler will be installed.

Locomotives

The CargoFlex Hybrid allows operators to gradually switch to DACs

With the CargoFlex Hybrid, Voith Turbo is offering a fully developed coupler for locomotives that is also compatible with the previous system. As well as installing the coupler, Voith Turbo also takes charge of preparatory work like feasibility analyses and support with the approval process for locomotives. This gives customers more flexibility and allows them to use the time as they see fit until European rail freight is switched over to DAC across the board.

Voith Service

- Everything from a single source: development, design, production – and service!

- Decades of product experience as an original equipment manufacturer and service provider

- Fast and smooth cooperation and best service thanks to a worldwide network of service locations

- Long-term partnership and planning security are guaranteed due to longstanding corporate stability