CargoFlex freight couplers: An important component of the European Green Deal.

The mobility transition is increasingly focusing on freight transport by rail. In Europe, the Green Deal is providing the roadmap to a sustainable future: The aim is for EU member states to be carbon neutral by 2050. An important tool in the transport sector is to shift more and more freight to rail. The aim is to increase the share of rail in freight transport from 18% in 2022 to 30% by as soon as 2030. The EU is subsidizing the new digital technologies necessary to achieve this ambitious goal.

The European DAC Delivery Program (EDDP) launched an initiative that tested various digital automatic coupler (DAC) prototype designs from different manufacturers and submitted recommendations for a European standard. The DAC is intended in particular to help accelerate the assembly of freight trains. The results of a research project by the European DAC4EU Consortium were also included in the decision-making process. Following extensive trials, the Scharfenberg principle, which is the basis for Voith's CargoFlex coupler, proved to be the most efficient solution.

EU Green Deal:

The roadmap for CO2 reduction

Climate neutral by 2050: The Green Deal calls for major efforts by all member states, especially in the transport sector.

Manual coupling slows down the train dispatching process

Hamburg-Maschen, Europe's largest marshaling yard, covers 280 hectares and is designed to handle 11,000 freight cars. But despite all the hustle and bustle, a visit to the site quickly reveals exactly where the bottleneck is in rail freight traffic – and that its potential is not being exhausted: Because the trains first have to be assembled before they can distribute the goods they carry. Every single freight car has to be coupled manually – in Hamburg-Maschen up to 3,500 times a day. That’s over 100 freight trains up to 500 m long, that yard workers have to couple or uncouple in the dangerous area between the wagons. With shunting, brake tests and railcar inspections, the train preparation alone can take up an entire shift.

“These processes have changed very little over the last 100 years,” says Niklas Weidert, Key Account Manager Freight Couplers at Voith Turbo. Railroad insiders joke that a truck will already have reached its destination before a goods train has even left the station. It is therefore high time to radically speed up and modernize these processes. Apart from the standardized automatic coupling system for around 450,000 freight cars and some 27,000 locomotives in Europe, the new standard will also digitize rail freight transport.

Previous composition of a freight train:

Workers at marshaling yards like Hamburg-Maschen have to flex their muscles, because the existing coupling process is extremely back-breaking work. This is why rail unions throughout Europe also support the introduction of the new technology and the automated processes offered by the DAC.

30 kg weight per draw hook

100 x per train of power, brakes, air

Reducing workload and improving safety

When using digital automatic couplers to connect two railcars, the brake air, power and data lines of the individual cars are also connected automatically. Until now, railroad yard workers have had to enter the dangerous space between the railcars and connect the 30 kg draw hooks to one another. And they have to do this up to 100 times per train, in windy and cold weather, day and night. “The DAC opens up completely new options for operators to improve safety for employees and increase the efficiency of transport operations,” says Niklas Weidert. He cites automatic brake testing as an example: “In future, before the train departs, the system will display the proper functioning of every single brake on the console in the driver’s cab within a matter of minutes. At present, the yard worker sometimes has to walk the entire length of the train, to one end and back again, which takes a lot of time in the case of a train that is 500 m long.”

When using the digital automatic coupler, the brake air, power and data lines of the freight cars are all connected automatically.

Driving force behind the digital automatic coupler

The project to introduce the DAC was initiated by Europe’s Rail, an EU Joint Undertaking, through the European DAC Delivery Programme (EDDP). As part of the project, the European consortium DAC4EU tested the use of the digital automatic coupler (DAC) in rail freight traffic across Europe. To this end, six companies from Germany, Austria and Switzerland won the tender for the research project “DAC Demonstrator for Rail Freight Transport” from the German Federal Ministry of Transport and Digital Infrastructure (BMDV) in June 2020. The members of the DAC4EU consortium are Deutsche Bahn and its subsidiary DB Cargo, the Swiss and Austrian rail freight operators SBB Cargo and Rail Cargo Austria, and the wagon keepers Ermewa, GATX Rail Europe and VTG.

A wide variety of systems were available, like the Scharfenberg coupler, the Schwab coupler, or the SA3 coupler, which is particularly widespread in Eastern Europe. The test program was identical for each type of coupler.

The principle behind the Voith CargoFlex coupler is the test winner

The tests revealed that the CargoFlex coupler from Voith Turbo, which is based on the Scharfenberg principle, significantly increases the derailment safety of freight cars compared with previous solutions. CargoFlex achieved the maximum number of points in all tests. Power and data lines were reliably connected without any complex control or actuation processes. Even in winter tests performed under extreme climatic conditions in Sweden, the Swiss mountains, and the climate chamber of DB Cargo in Minden, CargoFlex delivered an outstanding performance. It worked perfectly even at temperatures of minus 40°C and with half a meter of fresh snow thanks to technical adjustments to the front of the coupler. This meant that the Scharfenberg principle, on which the Voith CargoFlex coupler is based, was the only one to meet all the “knock-out” criteria. In the meantime, the follow-on project TRANS4M-R is designed to achieve further objectives, including at least 40% less time for train assembly.

In the next few years, the DAC is set to be retrofitted to 27,000 locomotives and 450,000 freight cars in Europe.

Structure of Voith Turbo CargoFlex coupler

Successfully trialed in practice: Since 2019, the CargoFlex coupler has been used in regular commercial operation by SBB.

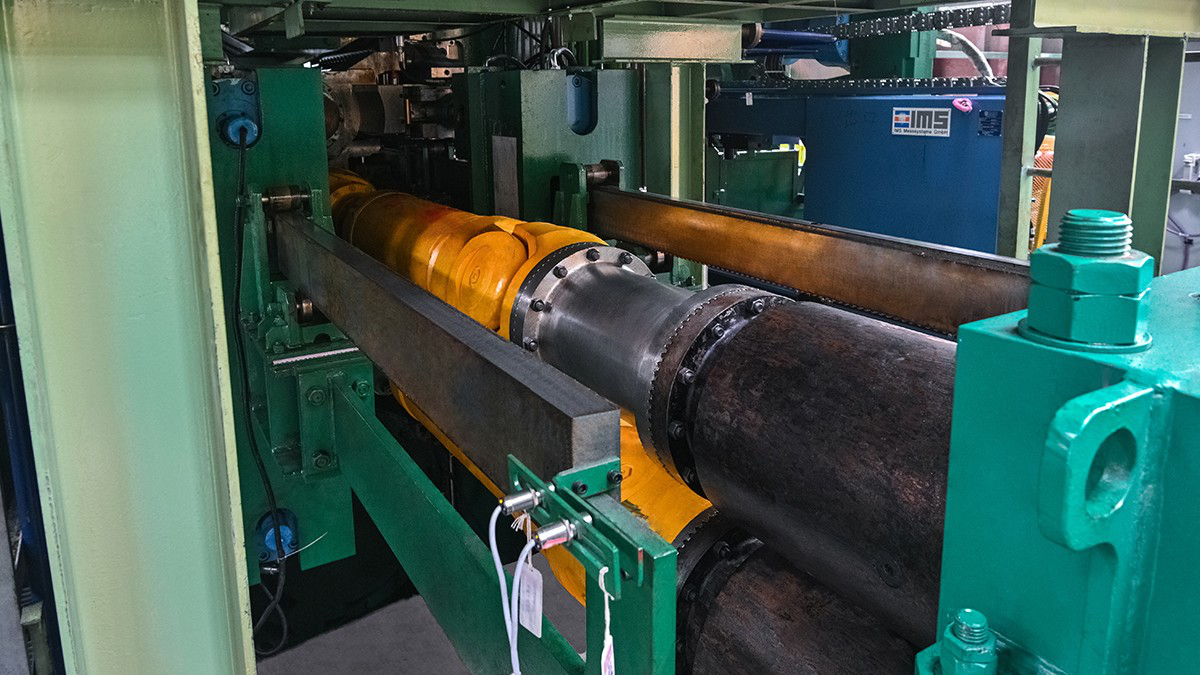

Head start with retrofitting: Voith Turbo is already preparing freight cars

Voith Turbo is already offering freight car operators a simple, risk-free way to break into the world of the automatic coupler. By modifying the cars to make them “DAC-ready”, the company is equipping existing freight cars with the CargoFlex energy absorption system. This “draw gear unit” is located in the freight car’s standardized UIC-530-1 installation space, while draw hook and buffers remain on the vehicle. In a second step, these will be dismantled simultaneously throughout Europe and the front part of the CargoFlex coupler will be installed.

In future, the couplers will transmit power and data throughout the entire train. “As a result, a simple freight car will not just become a smart car, but also a smart train that continuously supplies data, controls and monitors itself, and interacts with its environment,” says Niklas Weidert.

EDDP collaboration platform

The European DAC Delivery Programme (EDDP) is a Europe-wide open collaboration platform to bring together rail transport companies from all sectors. Its aim is to leverage technological advances to make European rail freight transport sustainable and attractive, and to drive forward the smooth, technologically and commercially viable conversion of freight services throughout Europe.