CargoFlex Hybrid:

Connecting the future, mastering the present.

The introduction of the digital automatic coupler (DAC) is gathering pace. Europeʼs Rail Joint Undertaking (EU-Rail) is currently preparing for intensive trials with 100 test trains called “Pioneer DAC Trains” (PDT) that will be fitted with the DAC and travel on Europe’s rail routes over a period of two years to accumulate practical experience in real-life operations. Rail companies, and operators and owners of locomotives can proactively apply to take part in the EU-funded testing program.

Following the test phase, EU-Rail will coordinate the rollout of the technology with the European DAC Delivery Programme (EDDP). Regardless of the Pioneer DAC Trains, operators of freight trains can already prepare for the switchover. With the CargoFlex Hybrid, Voith Turbo is offering a fully developed coupler for locomotives that is also compatible with the previous system. As well as installing the coupler, Voith Turbo also takes charge of preparatory work like feasibility analyses and support with the approval process for locomotives. This gives customers more flexibility and allows them to use the time as they see fit until European rail freight is switched over to DAC across the board.

Potential numbers of rail vehicles in line for a DAC conversion by 2030:

Experts from Voith Turbo are conducting the necessary migration analyses, providing comprehensive support – and giving operators a leading edge.

The CargoFlex Hybrid allows operators to gradually switch to DACs. It allows both coupling to a draw hook and automatic coupling, because the head can be set to the automatic or manual position as required.

Experts from Voith Turbo answer questions about the market launch of the CargoFlex Hybrid:

Thomas Spill,

Director Technical Service Rail at Voith Turbo’s Kiel facility

Markus Ilg,

Senior Sales Manager and Head of Service Freight Couplers, Voith Turbo

With its CargoFlex Hybrid for locomotives Voith is offering an interim solution for the switchover to the DAC. What’s it all about?

Markus Ilg: The introduction of the digital automatic coupler is a major European project. Even if the final details are still outstanding – above all as regards the exact timing and process for the changeover –, with the CargoFlex Hybrid we are putting rail companies and other operators of freight trains in a position to take action now. As the name says, the CargoFlex Hybrid coupler allows coupling to be done in the usual way, but operators can also couple other rail vehicles with the Scharfenberg type 10 system. This enables rail companies to gain initial experience with the DAC and test new processes in their operating procedures, gaining flexibility and saving time as a result. Customers who want to apply for one of the around 100 Pioneer DAC Trains are also ideally equipped to do so with the hybrid coupler.

Coming soon:

Large-scale DAC field test with 100 trains

The Europeʼs Rail Joint Undertaking (EU-Rail) Flagship Project 5 – TRANS4M-R is coordinating the path to market readiness of the DAC in the EU. In a previous project, Voith Turbo’s CargoFlex scored the highest number of points and was thus highly influential in the decision-making process for the future standard for the coupler head. The current development status of the digital automatic coupler – including the CargoFlex by Voith Turbo – is now being tested and trialed within the scope of Flagship Project 5 TRANS4M-R.

Freight train operators are currently being invited to apply to operate one of around 100 test trains that will run in real-life conditions to allow final experience to be gained before the Europe-wide introduction of the DAC. Participation in the project is funded by the EU.

If you would like to take part in a Pioneer DAC Train please email info-DAC@rail-research.europa.eu

You recommend that your customers should convert their locomotives in good time. Why is the new solution especially relevant in this context?

Thomas Spill: In our view, the conversion of locomotives is the starting point for the migration, which is what the project to switch over to the new digital automatic couplers is called. It starts with the vehicles that move everything. Although the relevant European committees are still discussing how exactly the changeover should take place, there will in all likelihood be a longer period during which all 450,000 freight cars and around 23,000 locomotives that are on the rails in Europe will be converted to the DAC.

The earlier the operators of freight trains get to grips with the DAC and the conversion the better it will be for them. This means they will be prepared as they enter the mixed operation phase with some railcars fitted with old couplers and others with DAC. Anyone wanting to continue to have flexible use of their locomotives needs a system that is compatible with both technologies. And that’s exactly what the CargoFlex Hybrid coupler offers. Incidentally, it is a permanent fixture on the locomotive or freight car, so there is no need for further investment after the switch to the DAC has been completed in full.

What steps are involved in integrating the hybrid coupler apart from mounting the component?

Markus Ilg: It starts with an expression of interest and an inquiry to Voith Turbo’s sales department or directly to our Competence Center for Locomotives at our Kiel site. There, our rail experts work with customers to check the type of locomotive and documentation available. Depending on model, one of our technicians will also inspect the vehicle in situ. Afterwards, we carry out a feasibility analysis and produce a detailed offer. The installation of the couplers then follows in Kiel or at another Voith facility.

Thomas Spill: Voith Turbo doesn’t just supply and install the digital automatic couplers; our experts also take charge of the modification to the vehicle itself. Because an important task in the migration process for CargoFlex Hybrid is to ensure the continuation of the approval. As a former manufacturer of locomotives, Voith Turbo has over several decades built up significant expertise in this area that can benefit our customers. In addition to the manual integration, the modification to the vehicle must be assessed and proof of rail transport safety provided. After all, each of the locomotives only has approval without DAC. We provide support with successfully navigating the change process with the relevant authorities. This saves our customers time and gives them a high level of process reliability.

What distinctive benefits does the Voith Turbo Competence Center for Locomotives offer?

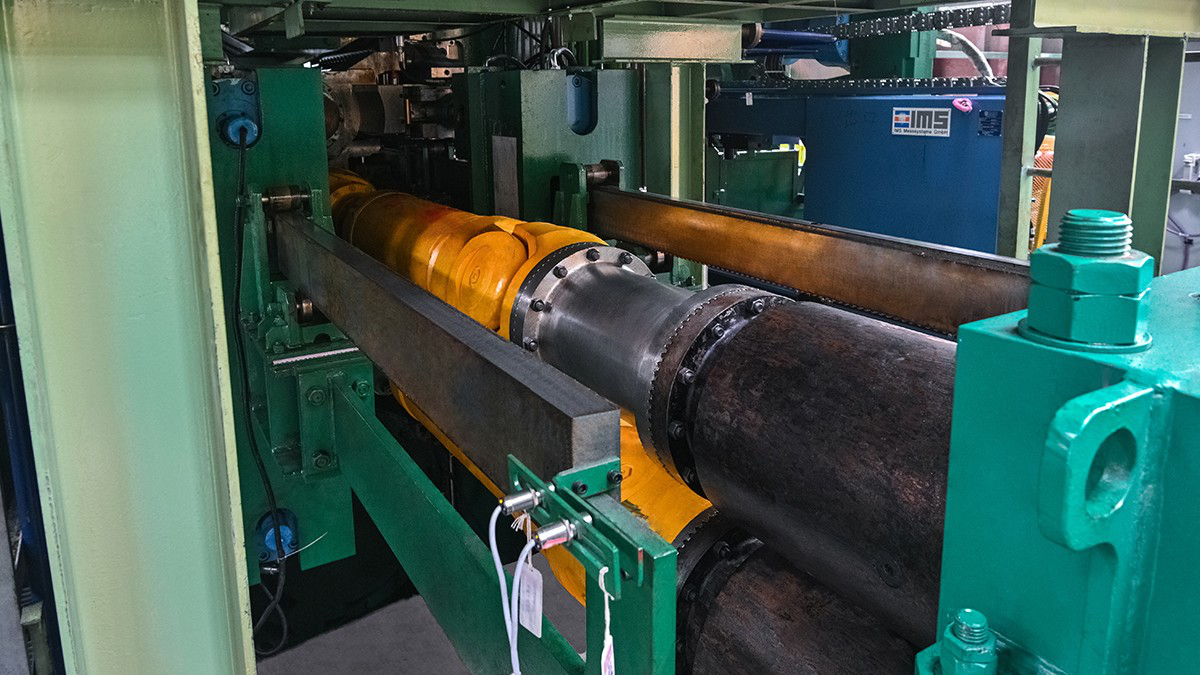

Thomas Spill: In Kiel our highly skilled and experienced team can draw on a top-class railway infrastructure. We have a railway siding that connects to the public rail network and can easily bring rail vehicles to our workshop. In the workshop halls, we can inspect locomotives from pits and raise them completely. This ensures optimum access and working conditions.

Markus Ilg: Speaking of the Competence Center, Voith Turbo’s rail expertise is regularly verified. As well as having all the necessary certifications for the rail segment, we are also a certified service company for maintenance on rail vehicles in accordance with the EU Regulation “Entity in Charge of Maintenance” (ECM). This governs how servicing on rail vehicles has to be carried out.

This means that we are ideally equipped to handle all tasks relating to maintenance and other work on rail vehicles.

Top-class infrastructure:

the Voith Turbo Competence Center for Locomotives in Kiel.

With the DAC, the EU aims to significantly increase the percentage of freight transport using rail. What impact does the new technology have apart from achieving sustainability goals?

Markus Ilg: As well as sustainability and the important issue of CO2 reduction, the technology is also strongly focused on efficiency. A new and much faster process for assembling freight trains will be established. The trains can transport larger tonnages because they can be longer, and in future they can also carry a wider range of goods as power and data lines enable the monitoring of loads.

For occupational safety too the system represents an immense upgrade. Safety was already to the forefront when Voith introduced the Scharfenberg coupler to passenger transport in the rail segment many decades ago. Manual coupling with heavy draw hooks and brake tests, which is how freight trains are still assembled, is hard physical work in a dangerous area. In view of demographic change in Europe, it will not be any easier in future to find suitable candidates for this job. By switching to the DAC, freight train operators are therefore also ensuring their operational readiness and protecting their business model.

Thomas Spill: Without doubt, rail is a means of transport that moves goods in an ecologically beneficial way. So that it can steer a competitive course into the future, the aspect of the digital added value that the DAC provides is also essential. Today’s freight cars consist exclusively of metal and mechanical parts and do not have any electrical or digital components. With the digital automatic coupler, not only is the coupling process automatic, but power and data are transmitted as well. The train composition and railcar sequence are captured digitally, as is the identification of train integrity and length – what is known as the train integrity check. This digitalization and the associated added values and efficiency increases in rail freight transport are in my view a key contribution to the successful future for rail freight.

The CargoFlex Hybrid allows operators to gradually switch to DACs. It allows both coupling to a draw hook and automatic coupling, because the head can be set to the automatic or manual position as required.