CargoFlex from Voith Turbo: European rollout draws closer.

Within the scope of the European Green Deal, the EU has set itself the ambitious target of having 30% of goods transported by rail. One of the keys to achieving this is much faster assembly and dispatching of freight trains as well as a substantially higher route capacity utilization. To realize these goals, freight trains and locomotives in the EU are to be equipped with digital automatic couplers (DAC).

Europe's Rail Joint Undertaking (EU-Rail) Flagship Project 5 – TRANS4M-R is coordinating the path to market readiness for the DAC in the EU. In a previous project, CargoFlex achieved the highest number of points and was thus highly influential in the decision-making on the future standard for the coupler head. The current development stage of the digital automatic coupler is now being tested and trialed in the Flagship Project 5 TRANS4M-R. This is initially being done in a separate rail yard of the Train Test Lab in Berlin. Demo trains will then travel through five European countries. Every step towards market readiness is being carried out with the intensive involvement of the DAC experts from Voith Turbo.

Voith Turbo is doing its utmost to get digital solutions on track in the rail freight sector as well: CargoFlex, Voith Turbo’s digital automatic coupler for freight trains, is an important building block on the road to the planned Europe-wide rollout of the technology.

Current CargoFlex development status

Current CargoFlex development status

Other functions

Other functions

2024 is an important year for CargoFlex, Voith Turbo’s DAC: In the year of the 150th birthday of its inventor Karl Scharfenberg, one of the most important pioneers in Voith’s history, CargoFlex is nearing its market launch in the EU. At the same time, the Voith facility in Salzgitter, where most of the development work on the CargoFlex is being done, is celebrating its 75th anniversary.

Preparations for introducing DAC to European rail freight transport are gathering pace

With no less than six flagship projects from Europe's Rail Joint Undertaking (EU-Rail), the EU is pursuing the goal of increasing the share of freight transport via rail in Europe to 30%. The digital automatic coupler is playing an important role in achieving this goal.

The mechanical principle behind the DAC was invented by Voith pioneer Karl Scharfenberg more than 100 years ago. Scharfenberg couplers have been used in passenger trains for decades. The main advantage of the Scharfenberg principle is that there is no need for manual coupling by rail workers in the dangerous space between railcars.

CargoFlex integrates new digital functions like automated brake tests. In addition, the digital data connection speeds up the assembly of freight trains, for example, and helps make better use of the capacity of rail networks.

In Flagship Project 5 TRANSF4M-R (FP5-TRANSF4M-R), the digital automatic couplers for freight cars and locomotives are being tested and trialed under realistic conditions – with the intensive involvement of experts from Voith Turbo. In various test series, the CargoFlex and couplers from three other vendors had to prove their functionality and reliability. The people in charge of FP5 also measure progress using “quality gates” which are common in the context of industrial developments. Initially on test rigs and then on rail tracks under test conditions.

The EU Joint Undertaking Europe’s Rail is working with the European DAC Delivery Programme (EDDP) to coordinate the progress of DACs for freight trains on their journey to market readiness, and these include Voith Turbo’s CargoFlex. The video explains how the introduction of the new coupler is set to expand rail freight transport and make it more flexible.

Overview Flagship Project 5

Trans4M-R

From 2023

Function tests in the Train Test Lab Berlin

> Determination of quality gates

> Performance of long-term tests

on test rigs and

separate rail tracks

Bring about market readiness by testing

> mechanical and digital functions,

> reliability and robustness,

> interoperability.

> Tests on freight car sorting and train assembly

on hump (in Mannheim)

2023-2026

Field testing

> Demonstrator train in Sweden and Norway

> Demonstrator train in Austria

> Demonstrator train in Italy

> Demonstrator train in Switzerland

Testing in the Train Test Lab

The rail experts from Flagship Project 5 TRANS4M-R defined typical application scenarios in rail freight transport, especially for the complex assembly of freight trains including marshaling. In the Berlin Train Test Lab, these test series are initially conducted on a separate rail yard under the management of DB Cargo. The FP5 team tested the gravity shunting of freight trains at the hump yard in Mannheim in the south-west of Germany. “Gravity shunting” is the term used by railroad workers to describe the process of sorting items of rolling stock that roll down a slope under their own power and are distributed to various tracks to be loaded or unloaded or reassembled into new freight trains.

As well as the DAC’s functional reliability, Flagship Project 5 is also investigating the aspect of interoperability. As several suppliers are likely to be offering the coupler, they need to couple smoothly with one another and the digital interfaces need to be compatible before they are trialed on public rail networks.

The Train Test Lab was provided with various freight trains and freight car models from several EU countries to test the DAC. At the end of the test series in Berlin and Mannheim, these freight cars will form part of the demonstrator trains with which the FP5 experts will test the DACs ahead of their use in real-life train operations through Sweden, Italy and Austria. The Swedish DAC demonstrator train recently started its test operations.

Preparation for DAC rollout in the EU

The objective of Flagship Project 5 TRANS4M-R is to strengthen European rail transport as the backbone of a robust, low-emission freight transport system. The necessary solutions are to be elaborated within the project in two technology clusters: Seamless Freight Operation, i.e., seamless or interoperable freight operation and Full Digital Freight Train Operation (FDFTO), i.e., the fully digital operation of freight trains. The involvement of Voith Turbo for the development of CargoFlex for the planned rollout in the EU is part of the FDFTO technology cluster.

FDFTO creates added value over and beyond the coupler alone. The system makes freight trains ready for the European Train Control System (ETCS) and digital signaling systems (DSTW in German).

FDFTO creates added value over and beyond the coupler alone. The system makes freight trains ready for the European Train Control System (ETCS) and digital signaling systems (DSTW in German). These national train control systems are being harmonized to produce a uniform European standard and will thus substantially simplify cross-border transports. Greater capacity utilization of rail networks is also possible, because trains can travel in shorter succession.

These national train control systems are being harmonized to produce a uniform European standard and will thus substantially simplify cross-border transports. Greater capacity utilization of rail networks is also possible, because trains can travel in shorter succession.

With its digital system functions, CargoFlex is making an important contribution in this context. For example, the data line makes an automatic, continuous train integrity check possible. This means that the integrity of the train with all freight cars is reported to the driver’s cab and control room – instead of just counting the cars mechanically at selected points along the route, which has been the process until now. The digital system also allows for longer freight trains than in the past: trains up to 750 m long and with 50 freight cars are possible.

The digital automatic coupler also simplifies the work flows for assembling freight trains and splitting them at their destination station. For example, cars can be “pushed off”, i.e., separated from the train during travel to enable them to roll into their designated tracks in the freight yard. CargoFlex can assume a lock position when rolling independently. This is known as the prevent coupling setting and it prevents the re-coupling of railcars in shunting operations.

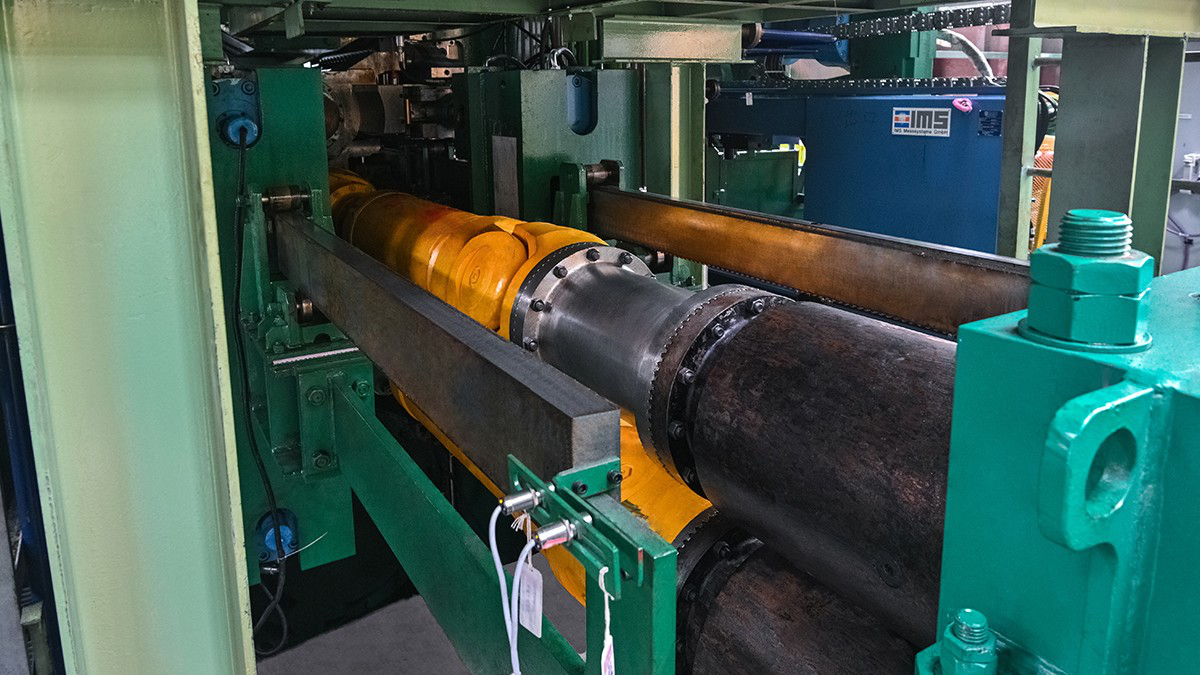

CargoFlex can already couple automatically and transmit power and data.

Three questions for

Christian Radewagen,

Senior Vice President Cargo Rail

at Voith Turbo

What are the current technical challenges for you and your team in achieving the EU approval for CargoFlex?

The requirements imposed on a Scharfenberg coupler in freight transport are very different from those in passenger transport. The couplers must be much simpler, but also more robust. We are dealing with higher force requirements. To this end, we needed to increase the fatigue strength from 200 to 300 kN.

Digital automatic couplers working on the Scharfenberg principle have already been in use in passenger trains for many decades. However, the technology has not been used so far for freight transport. How do the two applications differ?

Most freight trains are assembled to create new trains for each journey. Before that they are sitting on a rail yard, so they may be iced up. Due to the many cars that make up a freight train, defrosting them through heating is not an option, because the locomotive cannot provide the necessary energy to do this. There is also a greater amount of fouling compared with passenger trains. CargoFlex is so robust that it can permanently withstand these adverse conditions and still work reliably.

What steps remain before CargoFlex can be used throughout Europe?

The digital functions are currently still being added step by step. Meanwhile, we are making great progress at Voith Turbo and are ahead of schedule. We can already automatically couple and transmit power and data. Only the separation of the cars from the locomotive is still being implemented. However, for EU-wide operation, the interoperability is especially critical. Our CargoFlex needs to be able to work reliably with the DACs of three other vendors. It therefore makes sense for the last development steps to be coordinated centrally. I think that next year, or the year after at the latest, we will be able to test full DAC functionality in the demonstrator trains. When that’s completed, things will get really exciting. Because the next step is the retrofitting of a total 450,000 freight cars Europe-wide and around 27,000 locomotives, whose migration we are already preparing.

Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the Europe’s Rail Joint Undertaking. Neither the European Union nor the granting authority can be held responsible for them.