Protect your driveline with SafeSet intelligence

Rotating equipment drivelines are long-term investments worth protecting. Every minute of unplanned downtime caused by overload is a loss in production. With outstanding safety and reliability, Voith’s torque limiting couplings protect all components in the driveline, resulting in smooth operation, less wear and tear, and maximum performance of your equipment.

|

Features |

Benefits |

|---|---|

|

Accurate release torque |

Increases productivity |

|

Compact and customized design |

Easy driveline integration |

|

Set torque that remains constant over time |

No unwanted releases, which reduces repair time |

|

Instant torque limitation in an overload situation |

Protects the driveline and avoids expensive standstill costs |

Explore the next generation torque limiter

SafeSet EZi

Simplifying and adding value to the growing need for faster delivery times, more accessible and safer handling during operation, and simple maintenance of torque limiting couplings is now a reality with our newest generation of SafeSet EZi couplings.

Our SafeSet product portfolio

Voith's comprehensive product portfolio covers a range of torque limiting couplings with capacities from 1 to 20,000 kNm.

Tailor-made designs provide additional advantages to the production process. SafeSet, SlipSet, SmartSet, and AutoSet ensure the safe operation of the driveline by releasing or slipping at an exact torque level. In the event of a catastrophic, high-torque occurrence, the torque limiting couplings interrupt the power flow in the driveline, which minimizes damage and production downtime. The Voith Dtect System alerts you in real-time about torque overload situations, helping further protect your investment.

SafeSet – coupling with instant release

Features and benefits

Design features

- Torque range between 1 and 20,000 kNm, depending on model and use

- Adjustable torque settings to suit all applications

- Immediate release at a pre-set torque in the event of a torque overload

Benefits

- Maximum driveline protection — damaging inertia disengage at once

- Set torque remains constant over time

- Quick resetting for maximum uptime

- Custom-made to suit individual requirements

-

Torque limiting for increased performance in crushing SafeSet torque limiting couplings for belt drives and direct drives

PDFEnglish

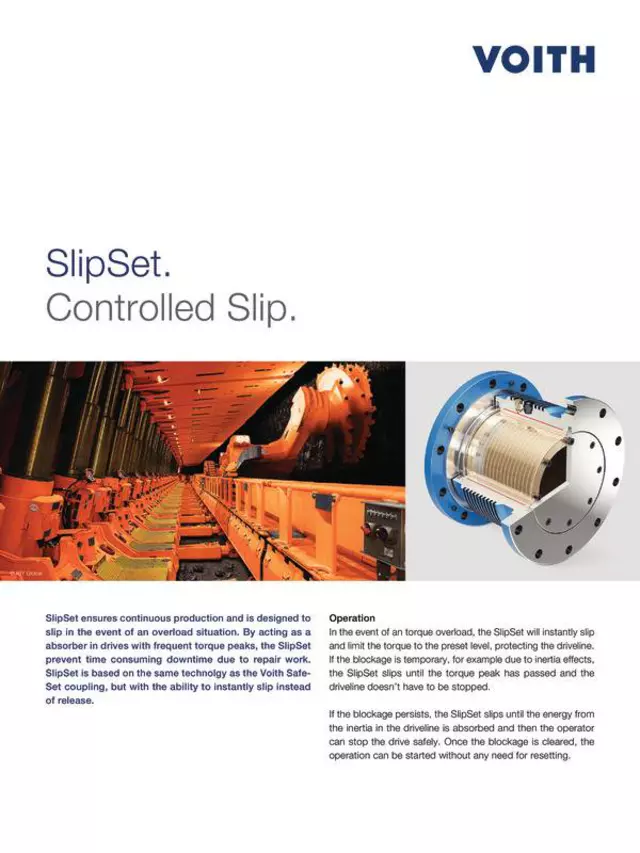

SlipSet – coupling with peak shaving

In a temporary torque overload, the coupling slips to limit the torque peaks and enables continuous production. If the blockage persists, the SlipSet coupling slips until the drive can be stopped for the obstruction to be cleared. To monitor the maximum slip angle possible, we recommend using the Dtect torque system.m.

Features and benefits

Design features

- Ideally suited for applications requiring short peak loads

- Adjustable torque settings from 50 to 100% of maximum torque setting

- Slip at a pre-set torque

- Immediate slip in the event of a torque overload

Benefits

- Ensures continuous production due to torque limitation without disengagement

- Minimized installation cost thanks to a compact design

- Less maintenance cost due to instant overload protection that protects your driveline from premature wear

SmartSet – coupling with peak ride through and controlled release

Features and benefits

Design features

- Ability to slip up to 120° during a torque peak

- Adjustable torque settings from 50 to 100% of maximum torque setting

- Mechanical slip and release mechanism

Benefits

- Ability to slip without release to reduce the short duration and dynamic peak torques

- Precisely adjustable slip and release torque

- Maximum driveline protection

- Full release during blockage

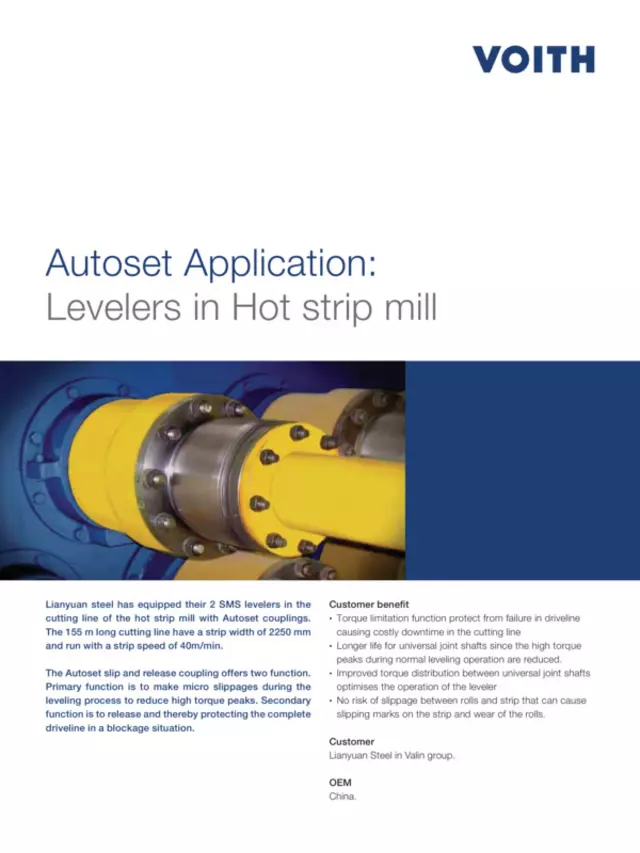

AutoSet – coupling with controlled slip and automatic reset

Features and benefits

Design features

- Ensures continuous production due to torque limitation without disengagement

- Automatic resetting of slip angle

- Complete disengagement during a long peak event

- Automatically resets itself to the pre-set torque limit after a longer overload/complete blockage

Benefits

- Improves production, as no resetting is needed for short peaks

- Lower maintenance cost with no manual resetting needed

- Less investment cost, as no additional equipment is needed

- Continuous operation, even during an overload, improves production uptime

Dtect – coupling monitoring system

Features and benefits

Design features

- Modbus TCP/IP standard

- Slip angle measurement

- Relay outputs

- Speed measurement

- Service indicator

- Ethernet connection

Optional features (on request)

- GSM module

- Multi monitoring

- Integrated HMI touch panel

Benefits

- Real-time monitoring of the driveline status

- Possibility to optimize driveline performance

- Integration with existing process monitoring systems enables platform-independent supervision of data

- Prevent costly downtime with proactive maintenance of a coupling

- Visual and audio warning indicators can be activated for making decisions and actions

- Increase uptime of the driveline

Helping you find your ideal torque limiting solution

Thank you for your enquiry

We are looking forward to providing the best solution for your drivetrain.Our team will be in contact with you.

Something went wrong. Please try again later.

EcoPressure

Biodegradable pressure fluid

When technology touches nature, environmental protection is our top priority.

The ideal pressure fluid for all torque limited couplings, EcoPressure can be used in all applications, and especially for ecologically sensitive areas like forestry, agriculture, waterways, and mining environments. This also includes all equipment and facilities operated in or near water treatment, water protection or surface water areas.

EcoPressure at a glance

Sustainable

- Biodegradable

- Environmentally sensitive

- Based on saturated synthetic esters and an environmentally friendly combination of additives

- EU ecolabel certification (Registration No. DE/027/079)

High performance

- Resistant to oxidation

- Excellent corrosion and EP protection

- Outstanding low temperature behavior

- Zinc-free

- Compliant with VDMA 24568 and ISO 15380

- An equivalent to conventional hydraulic fluids however this oil may even be superior in efficiency and operating behavior under certain conditions

Wide range of applications

Mining

- Crushers and grinders

- Conveyors and excavators

- Mixers and extruders

Steel and recycling

- Levelers

- Rolling and Steckel mills

- Plate and strip mills

- Shredders

Energy

- Gas turbines

- Compressors

- Wind power

Marine technology

- Propulsion

- Thrusters

- Water jets

- Ship loaders

- Dredgers

Rail vehicles and test rigs

- High-speed trains

- Test rigs

Construction

- Tunnel boring machines

Voith Service – how can we help you?

- Everything from a single source: development, design, production – and service!

- Decades of product experience as an original equipment manufacturer and service provider

- Fast and smooth cooperation and best service thanks to a worldwide network of service locations

- Long-term partnership and planning security are guaranteed due to longstanding corporate stability

Engineering services

Publications

Explore other related products

Voith connection couplings transmit torque backlash-free in a friction joint and transfer the most torque in relation to size. Thus, the customer benefits from high performance and more effective dimensioning of the driveline.

Get to know our product portfolio