Air systems for paper production

Innovative air systems for highest efficiency

Voith has developed a complete range of ventilation solutions for the paper industry. Our know-how in air-technology is the basis of effective solutions for new machines as well as existing systems.

With properly designed air systems, a significant reduction in energy costs and an increase in productivity are feasible. Effective air systems also lead to improvements in availability and quality. Moreover, they are elementary for conservation of building structure. Our products are designed for reducing energy costs and optimizing the production process and quality.

Application area at a glance

| Paper machine | Machine hall | ||

|---|---|---|---|

|

Drying

|

Coating & Sizing

|

||

| EcoHood |

|

|

|

| EOS dew point control (DPC) system |

|

|

|

| Heat recovery concepts including integration of heat pumps |

|

|

|

| Process ventilation |

|

|

|

| Building ventilation |

|

|

|

| EOS hall ventilation |

|

|

|

| Heating systems |

|

|

|

| Air conditioning systems |

|

|

|

Product range

EcoHood

Highest energy efficiency and heat recovery

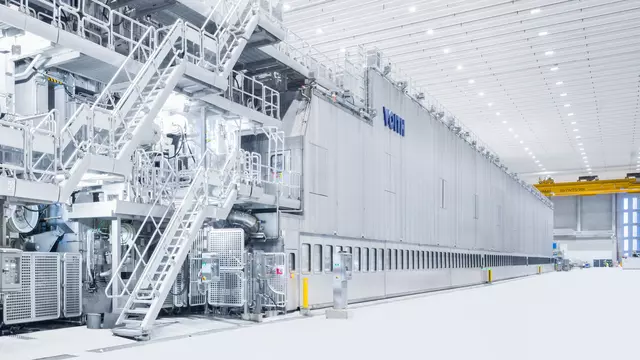

The Voith EcoHood encloses the dryer section in a special housing that still allows access for operation and maintenance with the highest level of safety.

Compared to open hoods or hoods with less insulation, very low heat and moisture get into the hall due to the superior insulation and modular design of the EcoHood. Thus, almost all of the vapor produced when drying paper can be utilized in the heat recovery system. The impacts on the climate in the hall are mitigated and the building is actively protected.

Dew point

On the one hand, a thorough capture of vapors is key to heat recovery for high energy efficiency in drying. On the other hand, the dew point of the hood is decisive, i.e., the possible moisture in the exhaust air due to the hood design. The higher the dew point, the less supply air and exhaust air is required, which also reduces power and steam consumption. Multi-stage heat recovery systems for heating of supply air, fresh and white water, as well as heating of the production hall, can often only be implemented and operated efficiently with a high dew point.

The EcoHood can be delivered in two versions, both suitable for new construction as well as for rebuilds.

EcoHood 62

The standard hood with an operating dew point of up to 62°C, for application in nearly all paper machines.

EcoHood 65

The hood with an operating dew point of up to 65°C for the highest energy savings. The amount of supply air and exhaust air can be reduced by almost 20%.

Your benefits with EcoHood

- High energy savings

- Suitable for all dryer sections, especially rebuilds

- Reduced operating costs

- Designed for best maintenance support

- LED interior light for additional savings (high temperature proof)

EOS dew point control (DPC) system

Saving energy with improved heat recovery

The dew point control system hood ventilation technology controls the supply and exhaust air quantities in the dryer section, thus reducing the amount of air and fresh steam required.

The dew point control system consists of sensors that measure the moisture in the hood exhaust air and a control algorithm that ideally tracks the supply and exhaust air quantities through speed control at the fans. Either constant exhaust air moisture is the basis for the control, or a stored product grade/air quantity matrix is used. This is advantageous for machines with a high portion of dirt in the hood exhaust air, since as a rule, exhaust air moisture sensors do not have sufficient measurement stability there.

By adjusting the dew point from 56°C to 62°C, an increase in heat recovery capacity of 19% and energy savings of 70% are achieved.

By using the dew point control system, the power requirement at the ventilator drive is reduced. This reduced power requirement is achieved since the air quantity reduction of 30% reduces power requirements by more than 60% with speed control of the fans. Accordingly, the fresh steam requirement and the air leakage from the hood (exhaust air quantity minus supply air quantity) are also reduced. Heat recovery performance increases as well.

The dew point control system hood ventilation technology is used in the air system of the dryer section and reduces the quantities of air, saving steam and power in the overall process.

Your benefits with EOS dew point control (DPC) system

- Improved energy efficiency of the dryer section and heat recovery system

- Reduced power and steam requirement due to lower supply and exhaust air flow

- Maximum efficient operation; the possible exhaust air dew point of the vapor hood is not utilized at grades with less water evaporation

- Environmental protection due to less CO2 emissions and lower primary energy consumption

Heat recovery concepts including integration of heat pumps

Highly efficient heat recovery concepts to reduce drying energy costs

A holistic consideration of the production process, including adjacent systems, as well as the optimal design of heat recovery stages can enable significant savings. Voith also offers professional energy audits to assist in optimizing existing systems and ideally integrating modern concepts.

A single-stage heat recovery system for heating the machine supply air typically utilizes only approx. 5-8% of the energy content of the hood exhaust air from the drying section. The majority of the energy just disappears through the roof. With multi-stage retrofittable heat recovery systems from Voith, including the integration of heat pumps, the energy of the hood exhaust air and other waste heat flows, such as the vacuum pump exhaust air, can be effectively utilized. In addition to the machine supply air, water for the process (fresh water, spray water, white water) and/or for heating the hall ventilation can also be warmed.

Thanks to a comprehensive understanding of the process as a full-line supplier, Voith can offer customized solutions to increase energy and cost efficiency. Voith strives to find the optimal solution for each customer to ensure maximum savings and sustainable production.

Process ventilation

Hood and machine ventilation technology – The core of every drying section

The hood and associated machine ventilation system form the core of every drying section. The dew point of the hood has a direct impact on the energy costs for drying. In addition, the dew point of the hood defines the potential for recovery of the energy used previously for drying the paper. High heat recovery rates can only be achieved if the hood dew points are high.

Voith offers you the right solution and perfectly matched systems for hood and machine ventilation technology – regardless of whether you install a new system or upgrade or expand your existing facilities:

- Hood supply and exhaust air systems

- Pocket/machine ventilation systems

- Provision of other machine-level systems (e.g., fabric cleaners, press tray heaters, stabilizers)

- Wet section exhaust systems with separators and spray systems

- Pulper exhaust systems

- Sizing press exhaust systems

The choice of system components in terms of design and material plus the configuration of the individual systems guarantee operational reliability, ease of access and long service life as well as simple, cost-effective maintenance and servicing.

Building ventilation

Safe removal of heat and humidity

Machine hall ventilation and air extraction systems ensure safe removal of heat and humidity from the paper mill. This creates a suitable production environment for the process and operating personnel and also actively protects the building.

Voith takes into account factors such as mill location, possible equipment positioning, optimum air distribution and air supply, and noise and fire protection, as well as cost-efficient energy supply, ease of operation and a maintenance program that incorporates a standardized spare parts inventory where possible.

Machine hall ventilation

Depending on application (new system/rebuild) and/or the area to be covered, various systems are available (displacement ventilation method, conventional ventilation using air grilles). Incoming air units are configured to suit the ambient conditions and installation options either as box, wall-mounted or large, free-standing units.

Ceiling ventilation systems

Ceiling ventilation systems avoid production disruptions resulting from condensation on the hall roof in wet areas. Tailored to the application at hand, we supply ceiling cross ventilation or heated forced ventilation false ceiling systems. Intelligent system configuration – with heat recovery as an option – ensures minimal running costs.

Machine hall air extraction

Our air extraction units in modular design can be installed on the roof or on an external wall. They feature good accessibility for maintenance and cleaning work plus an effective reduction in noise emissions. Voith offers special solutions for smoke extraction in the event of a fire.

EOS hall ventilation

Less energy for plant ventilation

The Voith EOS energy optimization system saves power and steam in new and existing plant ventilation systems, while the modular design allows gradual improvement of efficiency.

With the Voith EOS, the amounts of supply and exhaust air, as well as the consumption of hot water in a plant ventilation system, are adjusted exactly to the need and load. This saves steam and power, thereby lowering the primary energy requirement. In addition, the performance of integrated heat recovery systems is noticeably increased due to the improved control of temperature and water quantities, which further reduces consumption of fresh steam. In comparison to most existing systems that are controlled via an outside temperature matrix or heat curve, energy optimization with the Voith EOS can save several hundred thousand euros per year. Voith experts estimate the saving potential with a special simulation tool.

The Voith EOS can be used in new and existing plant ventilation systems.

Your benefits with Voith EOS

Energy savings

- Steam savings through higher heat recovery capacity and optimized flow temperature

- Less steam and energy consumption through load guided and, therewith, reduced hall supply and exhaust air quantities for the most part

- Less energy consumption at the heating pumps

Reliability

- Increased operating reliability – EOS makes sure that each consumer is supplied with sufficient energy

- More transparency of the systems; heating surfaces that are too small will be recognized quickly and can so be optimized for further energy savings

- Reduced operating costs through automatic control

Environmental protection

- Lower CO2 emission

- Less primary energy consumption

Heating systems

Heating energy supply

The heating requirement for hall ventilation may be more than 10 MW/h depending on time of year, equipment location and size of paper mill. Voith's intelligent heating energy supply concepts allow effective use of all waste heat from the process and thus reduce the primary energy demand to a minimum.

Even existing facilities heated with steam or hot water can be optimized using simple means.

Air conditioning systems

Air conditioning/cooling – A safe process control

For reliable process control and to create comfortable working conditions, we supply special solutions for air conditioning and cooling.

Voith supplies system solutions from simple control room cooling with split cooling systems to control room cooling systems with ambient air-cooling equipment and positive pressure systems. A chemical air filter can be integrated to prevent corrosion.

For cooling purposes, complete cold water systems, including refrigeration with air or water-cooled refrigerating units or well water-cooling systems, are used.

Control room cooling

Control room cooling systems remove waste heat and protect the switchgear from dust and corrosion.

Voith supplies system solutions from simple control room cooling with split cooling systems to control room cooling systems with ambient air-cooling equipment and positive pressure systems. A chemical air filter can be integrated to prevent corrosion.

For cooling purposes, complete cold water systems, including refrigeration with air or water-cooled refrigerating units or well water-cooling systems, are used.

Direct air conditioning of winders

Insufficient moisture in the area of the winder cutting blades can cause web shrinkage and tears, resulting in web breaks. Voith’s special air-conditioning systems prevent this problem and the ensuing production downtimes.

Air conditioning of finishing areas

Special air-conditioning systems to regulate a constant temperature and humidity in the room and/or around the production machine reduce the static charge in the paper in the finishing area (calender, winder, cross cutter) and thus ensure high productivity.

High pressure humidifiers or steam humidifiers are used for air humidification in compliance with the relevant hygiene standards.

Air-conditioning of operator stations, offices and staff amenities

A comfortable working environment is one of the prerequisites for efficient personnel. Voith designs and supplies ventilation and air extraction facilities with or without cooling for offices, staff amenities and control rooms, also in the form of split refrigeration systems.

Laboratory air conditioners

For quality assurance in the laboratory, Voith air conditioners guarantee a standard atmosphere. This is the only way to enable reliable measurements.

Transformer cooling

Waste heat is reliably evacuated by transformer cooling units, if the outdoor cooling is not sufficient, thus preventing transformer breakdowns.