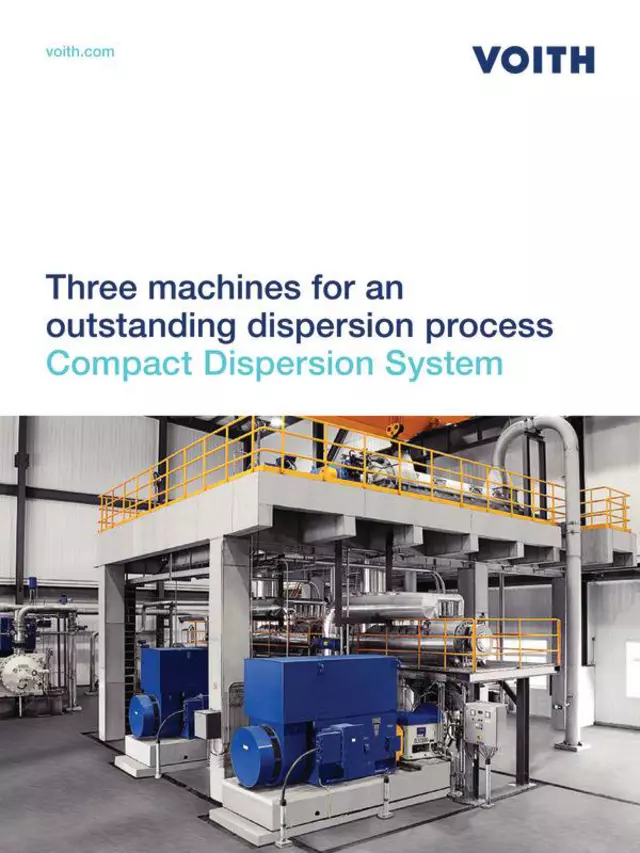

Compact Dispersion System

Reduce unwanted contaminants and improve optical characteristics

Dispersion is used in recovered fiber applications primarily to reduce the size of contaminants to avoid problems downstream in the papermaking process.

For white grades, dispersion also ensures the best optical properties. As residual ink particles are separated from the fibers in the disperger, efficient deinking can take place in flotation cells. If bleaching is required in the system, dispergers are used for an intense mixing of the bleaching agents with the fibers.

For brown grades, dispersion not only reduces the contaminants but also contributes to improve strength properties.

Voith’s Compact Dispersion System impresses with its reliable and high dewatering performance, quick and efficient steam heating and outstanding technology as a result of dispersion. The system provides reliable operation with only three machines. Thanks to the reduced number of machines, up to 35% less facility space is needed. Also, a simpler system means easy handling and high availability of the system. In addition, energy savings of up to 10% can be achieved.

The right machine for every task

| InfiltraScrewpress |

More homogeneous and continuous dewatering of the pulp |

| SpeedHeater |

Efficient heating, fluffing and homogenizing |

| InfibraDisp |

Outstanding dispersion results with low energy consumption |

| Thune Screw Press |

Optimally dewatered pulp |

| KRD Disperger | Stable pressurizable operation for high and consistent pulp quality |