Technical innovation and digital solutions

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive.

Voith’s operating business is bundled in three Group Divisions: Voith Hydro, Voith Paper, and Voith Turbo.

A large proportion of the world’s paper production is manufactured on Voith paper machines. A quarter of the energy generated worldwide from hydropower is produced with turbines and generators from Voith Hydro. Voith’s drive components are found in applications all over the world, both in industrial plants and in road and rail vehicles, as well as on the waters.

Clear structures and responsibilities

Voith GmbH & Co. KGaA is 100% family-owned. The advisory committee and the regulatory body are the Shareholders' Committee and the Supervisory Board. The latter is also the controlling authority for the Management Board.

Setting standards in our markets

Energy

Voith – Global player on the energy marketEnergy efficiency in the face of climate

Worldwide, a quarter of all electricity generated by hydro power is produced with technologies and services from Voith. In power stations all over the world, components and services from Voith ensure regular energy supplies.

Economic prosperity, social development and everyday life are based on secure and affordable power supplies. Worldwide, the trend towards the utilization of renewable and climate-friendly energy sources is accelerating, as the fight against climate change and diminishing fossil fuel resources intensifies. As a supplier of technologies and services for converting primary energy carriers into electricity, Voith plays a leading role in the energy market. International power station manufacturers and operators rely on the experience and the expertise of Voith engineers.

From Heidenheim to the Niagara Falls

In the energy segment, Voith can look back on a long tradition: the first Voith Francis turbine was built in 1873 for the Heidenheim textile manufacturer Plouquet. This was followed by the first major international project: twelve turbines for the hydro power station at the Niagara Falls. (1903-1910). In 1910 Voith delivered turbines for the first Chinese hydro power plant at Shi Long Ba.

Today, Voith develops innovative turbines, generators and automation technology for hydropower stations, among them large and small hydropower plants and pumped storage plants. In addition, Voith components and Voith service concepts at central points in different types of power stations ensure reliable and safe energy supplies for people and industries.

Oil & Gas

Efficient technologies for reliable raw material suppliesProducts and services from Voith in operation

Oil and gas play a key role in the production of petrochemical goods and in power generation. They are a prerequisite for economic prosperity. Voith offers reliable and efficient technologies and services to the oil and gas industry for extracting, transporting and processing these raw materials. The Group thus makes an important contribution to the reliable supply of oil and gas to national economies all over the world.

Operating in all regions of the world

Everywhere in the world, technologies from Voith support the production of oil and gas - often under very hard and adverse conditions. When these essential raw materials are extracted and processed factors such as plant availability, safety and robustness are vitally important. The demands on the applied technologies - for example on drilling platforms or on gas fields - are enormous. Apart from Voith components, Voith service specialists with their know-how are also your first point of contact whenever services for refineries and the petrochemical industry are required. Quality, reliability and experience are what really counts here. In Voith, our customers have found a solid partner.

Paper

A pioneer in paper makingNewspaper or kitchen roll - the world's paper mills produce on Voith machines

A world without paper? Unthinkable. Paper is an information carrier, an educational medium, a practical packaging material and an element of personal hygiene. Voith offers its customers technologies and services for the entire paper production process.

From newsprint and magazine paper to the production of tissue, which is used in everyday life as toilet paper, cosmetic wipe or kitchen roll - technologies from Voith are used in all sectors of the paper industry. In addition, the experts from Voith Paper look after the maintenance of all relevant machines.

A large share of the global paper production is performed on Voith machines

Paper making has a long tradition at Voith. As early as 1859, Johann Matthäus Voith built the first wood grinder for the production of paper from wood fiber. Today, a large proportion of the world's paper production is performed on Voith paper machines. Technologies for efficient and resource-sparing manufacturing methods are taking up an increasingly important role.

New processes for resource-sparing paper production

As technology leader, Voith focuses on less energy consumption, less fiber usage and more flexibility in operation to fulfill industry demands. Voith therefore offers its customers state-of-the-art technologies for cost-effective and resource-sparing production of, amongst others, hygienic paper. In cooperation with colleagues from Ravensburg in Germany, the employees at the Voith Paper Center of Competence in São Paulo, Brazil, have developed the so-called ATMOS technology for the production of premium tissue paper from 100% recycled fiber.

Raw Materials

Reliable at all timesVoith technologies help to extract and transport important raw materials

At first glance, they often go unnoticed, but couplings, gearboxes and many other Voith components are in non-stop operation in conveyor systems all over the world. Above and below ground, they contribute to the constant availability of raw materials such as coal, copper, nickel, etc., for industrial processes.

Be it universal joint shafts and hydraulic presses for steel mills, or hydro-mechanical turbo couplings for conveyor belts in open-cast mining - steel and mining companies traditionally rely on the specialists from Voith. In these industries, machines have to be particularly reliable and efficient. With their wealth of experience, Voith engineers develop and produce components and machines that set universal benchmarks for quality.

A large percentage of machinery produced by Voith operates in Asia

The Voith portfolio covers a wide range of technologies, in order to produce, transport and process raw materials such as coal, copper, steel and nickel. The market for these technologies is growing continuously. Ever increasing energy requirements call for more and more coal. But especially in emerging markets industrial production is continually rising - and therefore also the need for raw materials. In Asia, the demand is especially huge: nearly half of all plants produced by Voith for the raw materials industry are operating on the Asian continent.

Transport & Automotive

Mobile, innovative and eco-friendly

Voith sets standards in transport & automotive

Worldwide, more and more goods are being transported, more and more people travel or commute to their workplace. Metropolises rely on intelligent public transport systems, long-distance haulage routes connect the world. Voith supports these developments with innovative and sustainable solutions.

Voith is one of the leading suppliers of mobility technologies and services in the transport and automotive market. We develop reliable, resource-sparing, low-emission products and therefore make an important contribution to safety, efficiency and climate-friendliness. Voith service specialists work for all major automobile manufacturers and ensure smooth, efficient and cost-saving production processes with modern service concepts.

Mobility for people

Voith has been meeting the growing challenges of public and long-distance transport with innovative solutions for many years. Be it final drives or cooling systems and frontends for high-speed trains or automatic transmissions for citybuses - all over the world, Voith technologies make sure that people stay mobile. Especially in megacities such as Shanghai or São Paulo, Voith technologies in metro systems and citybuses make a vital contribution towards safe mobility.

But Voith technologies and services also move traffic on the waters and in the air, for example with propulsion and control systems for ships, with Voith Water Tractors and with engineering services for the aviation industry.

Ideas for the drives of tomorrow

Voith engineers are always looking for opportunities to make transport systems even more eco-friendly. Hybrid drives are among the key technologies in the search for lower fuel consumption and lower CO2 emissions. The experiences and results gained by Voith engineers in recent years during their work on hybrid drives for citybuses are now also used in other areas, for example for the development of hybrid solutions for new, low-emission rail vehicle drive systems.

One company – three Group Divisions

Voith is active in a wide variety of markets and therefore divided into three Group Divisions: Voith Hydro, Voith Paper and Voith Turbo. Each Group Division offers individual solutions with high-quality products.

The innovative spirit of Voith enhances our markets and adds momentum.

Voith Hydro

Full-line supplier for hydropower plant equipment

With its product and service portfolio, Voith covers the entire life cycle and all components of large and small hydropower plants: from generators, turbines, pumps, electrical and mechanical power plant equipment and automation systems such as measuring, control and command systems, to services including spare parts deliveries and maintenance work.

Your requirements. Our services.

Service

Regular inspections, maintenance and, if required, repairs are essential to make sure that hydropower plants produce electricity continuously and reliably.

With the life cycle service concept we offer a comprehensive service package that ensures the functionality and efficient operation of plants across their entire life cycle.

Automation

We develop automation concepts that are individually tailored to each hydro power plant, ensuring reliable and economical operation of hydro power stations.

Modernization

In an age of growing energy demands, the modernization of existing hydro power plants makes an essential contribution to securing energy supplies. Modernization projects can achieve significant increases in output and thus higher energy yields.

Small Hydro

Small hydro plants play an important part in generating power from renewable energies. With an installed output of up to 30 megawatt they are used in all places where natural conditions or existing infrastructures allow such a project.

Pumped storage plants

Pumped storage power plants pave the way for the further development of renewable energies. Voith Hydro has more than 100 years of experience with pumped storage power plants and delivers equipment for the most advanced and efficient plants in the world.

Large Hydro

Large hydro power stations are the world's most efficient source of renewable energy. They provide energy for growth regions such as Brazil, China and India and have also ensured reliable power supplies in developed countries for many decades. They make sure that millions of people get light and heating.

Driven by experience

Large, long-term projects which are Voith Hydro's daily business require a sure and experienced management.

Certificates & quality marks

All of our worldwide locations are certified to international standards for quality (ISO 9001), environmental protection (ISO 14001) as well as industrial health and safety (OHSAS 18001).

Integrated Management System: Voith Hydro has introduced an internal management system to ensure that quality standards and certificate are worldwide identical for all units.

Voith Paper

Partner and pioneer in the paper industry

Together for sustained success

As technological leaders we continuously develop new products and services to support our customers in managing these challenges. With our resource-sparing new developments we make a positive contribution to the environment and thus ensure the sustainable success of our customers.

Voith combines knowledge and experience for highly efficient paper mills, offering top performance in every sector and for every paper grade.

Stock preparation

A large percentage of the costs for fiber, energy and fresh water arise during the stock preparation stage. Consequently, the potential for savings is particularly high in this field. In addition, the stock preparation process has a decisive influence on the paper quality and the operation of the paper machine.

Voith has the know-how and engineering experience to provide highly advanced technologies for the stock preparation of primary and secondary fibers. We have been offering pioneering solutions for many decades to meet the high requirements of our customers on fiber quality.

Paper machines

High productivity of the paper machine and continuously assured high paper quality are major prerequisites for economical paper production and the smooth further processing of the paper. In order to ensure both, we regard all process stages of the paper machine as an entity. Resource-saving and efficient production is only possible if all components used within the manufacturing process are technically perfected and if sub-processes are aligned to each other.

This applies both to new paper machines and to rebuilds of individual sections. Whenever a new paper mill is designed, we take all influencing factors into account right from the start, in order to achieve optimum economic and ecological results.

Automation

Voith develops and implements comprehensive automation solutions for the entire paper production process from preparation of the raw material to the end product, perfectly tuned to your requirements. This results in a highly integrated system architecture on a uniform platform. It combines the machine control system, process control system, quality control system, motors and drive control system with a universal and open automation system. Voith Automation solutions make a vital contribution to a continuously high paper quality and productivity of paper production lines.

Consumables

Paper machine clothing, press sleeves, rolls and roll covers play an important role in the paper making process. They have a decisive impact on the operation of the machine and are vital for good paper quality. Due to lower wear they contribute to reduced production costs.

The optimized interaction between clothing, press sleeves, roll and roll cover, including doctoring is therefore one of our priorities. As a result, the productivity of the paper machine and the paper quality can be improved or kept at a permanently high level.

Services

It is a continuous challenge to achieve high paper quality throughout the service life of a paper machine and at the same time to ensure high system availability. Especially since ambient and raw material conditions as well as the requirements for paper quality are permanently changing. Preventative maintenance and continuous optimization are thus increasingly gaining in importance.

Service experts from Voith support our customers in facing this challenge: from product services to optimizations of entire production lines. Voith customers benefit from high service quality, reliable production processes and reduced maintenance costs. With our worldwide network of service locations, we are always close to our customers.

Environmental solutions

The intelligent use of resources like raw materials, water and energy are often as challenging to modern production facilities as the production process itself. Voith Paper provides technologies for the efficient handling of raw materials, the optimal integration of subsystems for water, sludge and rejects, the utilization of residual materials and waste water (effluent) for producing energy as well as the recirculation of clarified effluent.

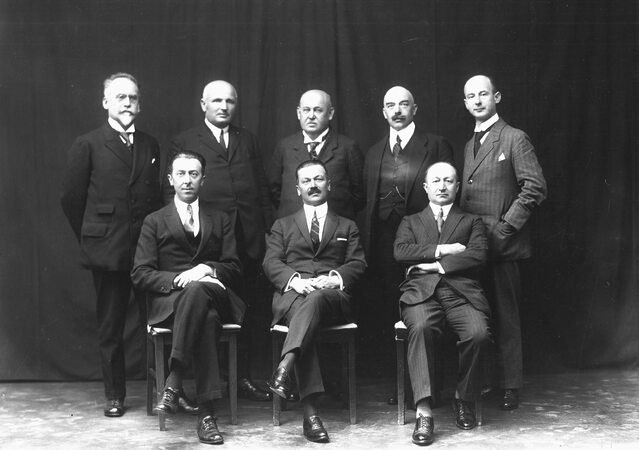

The Division Paper Management Board

Our Division Paper's board of management consists of long-term Voithians with extensive experience in the papermaking industry.

Voith Turbo

For your industries.

Voith serves a wide range of markets with an even so wide range of products and services. The experience and skills of our Division Turbo's management board reflects this with members coming from various industries.

Certificates

Division Turbo general

Voith works in accordance with a central, globally valid quality, energy, health, safety and environmental management system. All locations, certified according to 45001 & ISO 14001 are integrated within a Voith matrix certificate.

- Quality Management System ISO 9001 PDF 0.33 MB English

- Quality Management System IATF 16949 PDF 0.26 MB English

- Quality Management System IRIS 22163 PDF 0.40 MB English

- Health, Safety and Environmental Management System PDF 0.28 MB English

- Energy Management System PDF 0.28 MB English

- Certificate Welding 1585-2 PDF 0.10 MB English

From acting to understanding

Learn more about how we interact with the society and our colleagues. Which role do sustainability and compliance play for us and how does it feel to be a Voithian?