Optimization Solutions for Pulping

Get the best pulp quality

With the right technology, efficient pulping of virgin pulp and recovered paper in stock preparation leads to reduced specific energy consumption. In addition, bottlenecks in pulping capacity are eliminated and improvement in pulping efficiency is ensured. Our pulping rotors and screen plates meet these requirements by improving flow and pulping properties of the stock suspension.

Rotors and screen plates

We offer components, spare and wear parts for maintenance and optimization purposes for the following machines:

| LC Pulper | HC Pulper | Under machine Pulper | Detrashing / Discharge | Coarse Screening | Others | |

|---|---|---|---|---|---|---|

| Virgin pulp | Recovered pulp | |||||

| IntensaPulper IP-V | IntensaPulper IP-R | Pulper HDC | Pulper CP | IntensaMaXX | Combisorter | Contaminex CM |

| Pulper VS | Pulper UP | Pulper HDS | Pulper AK | Contaminex CMV | Turboseparator | Ragger |

| Pulper VSAP | Pulper HDST | Fiberizer | FiberSorter | |||

| Pulper AP | ||||||

| Pulper ST | ||||||

Pulper rotors

|

|

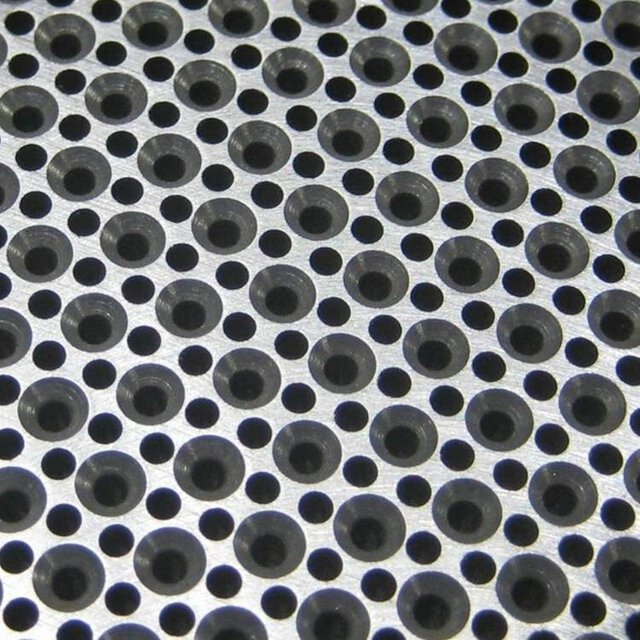

Pulper screen plates

|

|

The new design of the screen plate enables a clear increase in service life, resulting in fewer maintenance shutdowns. In addition, the design reduces the lateral forces on the bars. As a result, less rejects are shredded, which otherwise would have to be separated in the subsequent process at great expense. In addition, the wear on the bars is significantly reduced.

Rotors for flat screen machines

| Application | Detrashing / Discharge | Coarse Screening | |||

| Rotor name | Bow rotor | Star rotor | Vertical rotor | Bow rotor | Star rotor |

| Machine type | IntensaMaXX | IntensaMaXX | Combisorter | Turboseparator | Turboseparator |

| Contaminex | Contaminex | FiberSorter | |||

| Fiberizer | Fiberizer | Combisorter | |||

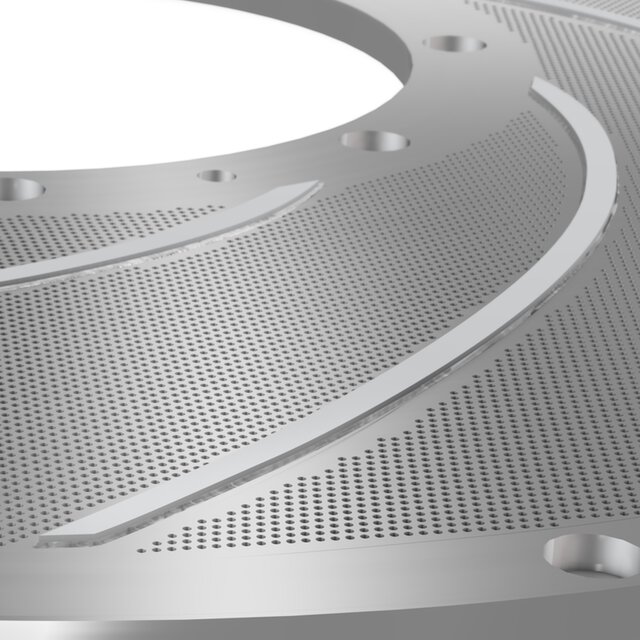

Screen plates for flat screen machines

|

|

Screen plates material quality

Screen plate material for all kind of screen plates is available in four qualities to match the customers operation condition, which means chemical load and raw material.

- Standard: The basic solution

- Comfort: Most common quality with original equipment

- Premium W: For highest abrasive wear, low chemical load

- Premium C: For high abrasion and high chemical load

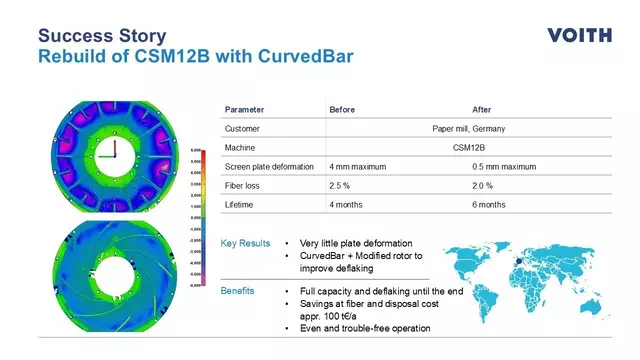

Progroup Paper PM1 GmbH has been successfully utilizing CurvedBar technology in their CombiSorter, leading to significant improvements such as enhanced running properties, reduced screen plate wear, and increased operational stability.

Watch the full interview to learn more about their experience!

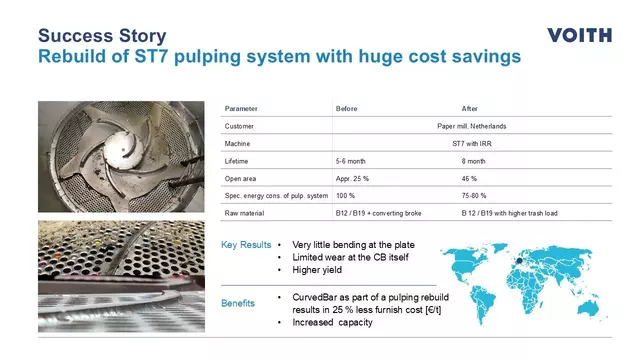

Rebuild of pulping systems

IntensaTechnology from Voith provides quick and intensive mixing of fibers in pulping. With existing LC (low-consistency) pulpers, the rotor geometry and flow characteristics of the pulp are changed, and the stock consistency is increased in a comprehensive rebuild. With the IntensaTechnology rebuild components, energy savings of up to 50% can be achieved. A doubling of pulping capacity is also possible. The rebuild to IntensaTechnology can also be done on older Voith pulpers and on pulpers from other manufacturers.

The particular orientation of the rotor-screen unit on the top of the asymmetrically shaped tank ensures that no vortices can form inside IntensaMaXX. Development of spinnings is thus successfully counteracted, and even maximum contaminant contents are not a problem. Reject discharge in a downward direction ensures reliable removal of contaminants. A rebuild to IntensaMaXX is worthwhile in general for capacity increase or as replacements of detrashing machines such as Fiberizer, Contaminex, CMS and CMV or machines of other manufacturers.

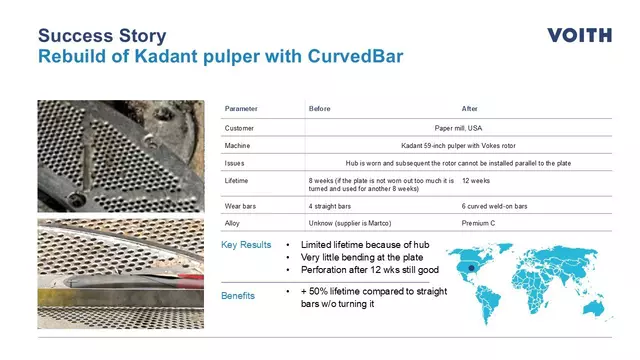

Have a look at our latest success stories:

Your regional contact

Do you have any questions? We are happy to help you find the perfect pulping rotor and screen plate for your application!

Discover our service portfolio Servolution

The condition of the screen plates and rotors is elementary for an economical and efficient operation. Thanks to our expertise, we can guarantee perfect geometry even after many processing cycles. Thus, after our service, the function of your rotor is 100% like a new rotor. With our service workshops we are present worldwide and therefore also close to you! Together we will find the right offer for you.

Rotor refurbishment service

Heavy contaminants in recovered paper cause wear to the working elements of your stock preparation machines. In almost all cases, proper performance of these machines depends upon maintaining the original design geometry of the working elements. Therefore, we offer a comprehensive rotor refurbishment service. Our services are applicable to all rotor types and screen plate combinations of the stock preparation equipment, irrespective of the manufacturer and type of pulper.

Order your spare and wear parts online

In the Voith Paper Webshop, the ordering of spare and wear parts is simplified. Customers can opt to search for the spare parts they need using a clearly arranged tree structure or the order number, which may also be a customer-defined internal part number. Your benefits with the Voith Paper Webshop:

- Personalized area

- Real time data availability

- Optimized business processes

- Order tracking

- 24/7 convenience