Precise speed control – Fast amortization

Using the Vorecon allows you to control the speed of your driven machine. Your process is carried out at exactly the speed required. As a result, the process runs with optimal efficiency saving you costly energy.

No matter whether you build, operate, design or modernize your drive systems, there are always two common goals: high equipment availability and reduced overall operating costs. Vorecon helps you to achieve this very effectively.

Benefits at a glance

With the Vorecon, you avoid costly downtime so overall your system is more productive. At the same time, you use less energy and installation space while enjoying both low investment and maintenance costs.

High reliability

> 48 years Mean Time Between Failures (MTBF)

Lowest Total Cost

of Ownership (TCO)

95%

Up to 95% peak efficiency

600

More than 600 oil & gas installations

30 years

Design life > 30 years

Minimum installation space

Small footprint and weight

OnCare.Health Vorecon

Are you interested in minimizing maintenance costs and increasing the availability of your critical drivetrain? Discover our self-learning diagnostic system that monitors your Vorecon’s ‘Heartbeat’ in power, oil and gas applications!

The self-learning diagnostic system that monitors your Vorecon’s ‘Heartbeat’ in power, oil and gas applications

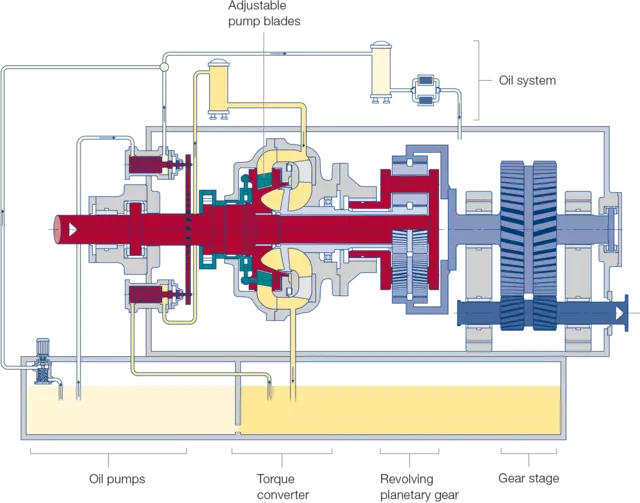

How the Vorecon works

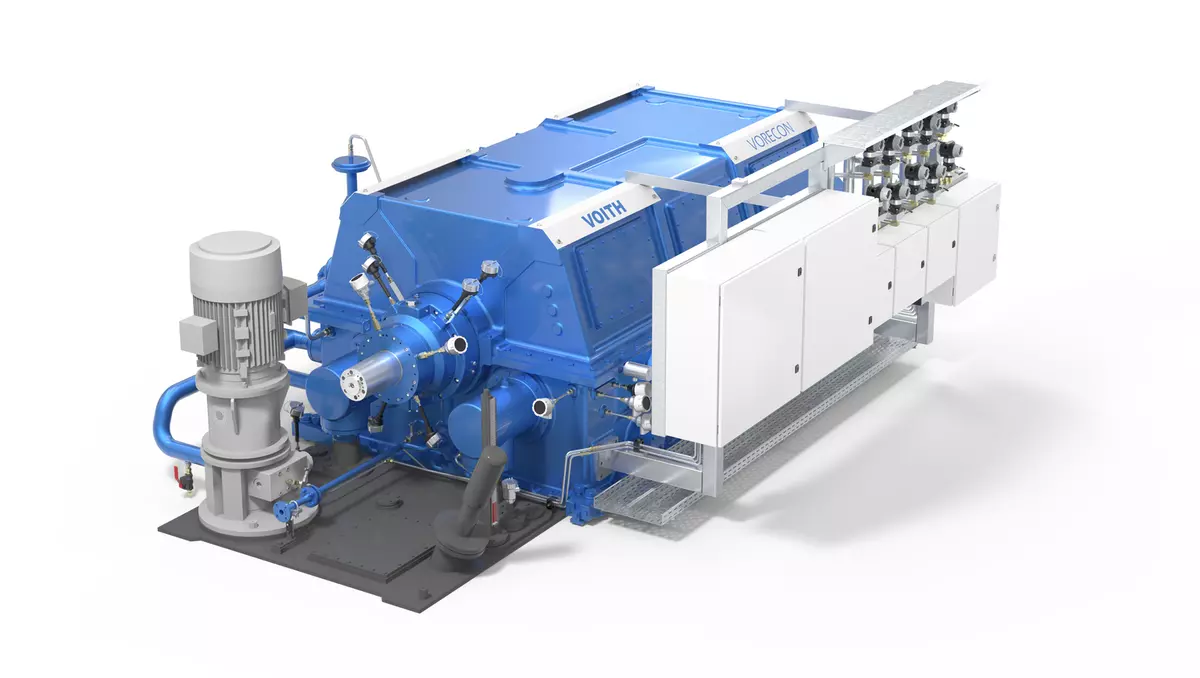

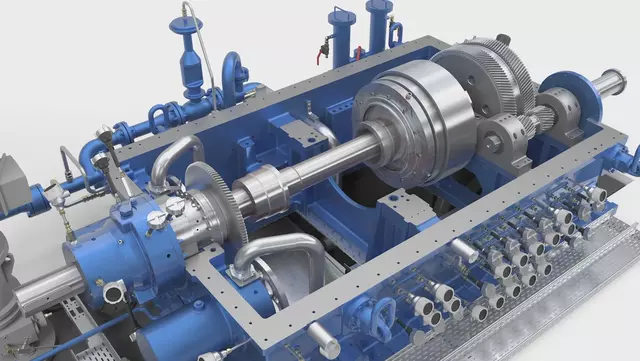

The Vorecon is a hydrodynamic variable speed planetary gear for transmission of up to 50 MW and output speed up to 20 000 rpm. It combines reliable mechanical design with hydrodynamic power transmission. In the driveline, the Vorecon is located between the drive motor and the driven machine.

The most significant proportion of Vorecon’s input power flows directly from the input shaft to the output shaft. At the same time, the hydrodynamic torque converter diverts a small proportion of the input power to the output shaft through the superimposing gear. The power splitting principle results in the Vorecon achieving very high efficiency.

Product range

The Vorecon product range comprises various types and configurations, enabling us to respond to your requirements. Together, we choose the Vorecon that best matches your drive and system.

RWE

Type RWE – Economical and compact

RWE sectional diagram

Function

- The torque converter fills immediately after starting the motor and branches off a small proportion of the input power.

- The driven machine is decelerated to a minimum speed.

- A fixed planetary gear transmits the power branched off to the revolving planetary gear (superimposing gear).

- The revolving planetary gear increases the power again.

- Speed control is applied using the adjustable guide vanes in the torque converter.

- The integrated oil system fills the torque converter with operating oil. At the same time, the Vorecon supplies the drive motor and the driven machine with lubricating oil.

RWE characteristic curves

Special benefits

- The Vorecon RWE is a cost-effective and straightforward solution for high-speed turbo compressors and boiler feed pumps with a reduced control range.

RWC

Type RWC – For starting-up the motor load-free

RWC sectional diagram

Function

- The hydrodynamic coupling is emptied when the drive motor starts and the clutch are opened; this indicates the drive motor and the driven machine are decoupled, and motor start-up is essentially load-free.

- The hydrodynamic coupling is filled after the drive motor is running and begins to transmit power. The driven machine is then gently decelerated to minimum speed.

- The clutch closes and bypasses the hydrodynamic coupling.

- From then on, the Vorecon RWC operates similarly to the Vorecon RWE. The speed control of the driven machine is applied using the adjustable guide vanes in the torque converter.

RWC characteristic curves

Special benefits

- The drive motor starts unloaded, and the driven machine can be started under weak power grid conditions.

- Driven machines with a high mass moment of inertia are easier to start up.

RW

Type RW – For a wide range of control

RW sectional diagram

Function

- When starting up the drive motor, the hydrodynamic variable speed coupling is emptied, and the clutch is opened. This means the drive motor and the driven machine are decoupled, and motor start-up is essentially load-free.

- In the lower control range, the hydrodynamic variable speed coupling is filled and transmits power. The torque converter is emptied and thus is non-operational within this control range. The speed control of the driven machine is achieved via the adjustable scoop tube, which determines the filling level of the operating oil in the coupling and, therefore, the power transmitted.

- The retarder (hydrodynamic brake) is filled with oil and keeps the fixed planetary gear at a low speed.

- The clutch closes and bypasses the variable-speed coupling to achieve the upper-speed range.

- The retarder is emptied, and the torque converter is filled.

- From then on, the Vorecon RW operates similarly to the Vorecon RWE. The speed control of the driven machine is applied using the adjustable guide vanes in the torque converter.

RW characteristic curves

Special benefits

- The Vorecon RW is the ideal control combination for driven machines with a comprehensive control range – mainly pumps and blowers

- In addition, the Vorecon RW offers the same advantages as the Vorecon RWC, such as a load-free motor start-up and easy start-up of driven machines with a high mass moment of inertia.

RWE-M

Type RWE-M – Economical and modular

RWE-M sectional diagram

Function

- When starting the motor, the hydrodynamic couplings are filled, and the torque converter is emptied. The hydrodynamic couplings thus connect the stationary gear with the input shaft. This results in a very low speed on the output shaft, and the driven machine takes on a little power. This relieves the motor when starting up.

- After starting up the motor, the hydrodynamic couplings are emptied, and the torque converter is filled. The driven machine is decelerated to a minimum speed.

- From then on, the Vorecon RWC-M operates similarly to the Vorecon RWE-M. The speed control of the driven machine is applied using the adjustable guide vanes in the torque converter.

RWE-M characteristic curves

Special benefits

- The Vorecon RWE-M is a cost-effective and straightforward solution for high-speed turbo compressors and boiler feed pumps with a reduced control range.

- The modular design with horizontally split housing allows service work to be carried out quickly and effectively, which is an essential aspect of offshore systems.

RWC-M

Type RWC-M – The economically-priced modular version for starting up the motor load-free

RWC-M sectional diagram

Function

- When starting the motor, the hydrodynamic couplings are filled, and the torque converter is emptied. The hydrodynamic couplings thus connect the stationary gear with the input shaft. This results in a very low speed on the output shaft, and the driven machine takes on a little power. This relieves the motor when starting up.

- After starting up the motor, the hydrodynamic couplings are emptied, and the torque converter is filled. The driven machine is decelerated to a minimum speed.

- From then on, the Vorecon RWC-M operates similarly to the Vorecon RWE-M. The speed control of the driven machine is applied using the adjustable guide vanes in the torque converter.

RWC-M characteristic curves

Special benefits

- The drive motor starts unloaded. The driven machine can also be started under weak power grid conditions.

- Driven machines with a high mass moment of inertia are easier to start up.

- The modular design with horizontally split housing allows service work to be carried out quickly and effectively, an essential aspect of offshore systems.

RWE-NX

Type RWE-NX – Lowest Total Cost of Ownership, upgradeable basic gear

RWE-NX sectional diagram

Function

- During the starting sequence the torque converter is filled in the beginning and then branches off a minor portion of the input power.

- The power branched off is superimposed in the revolving gear.

- The driven machine is accellerated to minimum speed.

- The speed control is applied using the adjustable pump blades in the torque converter.

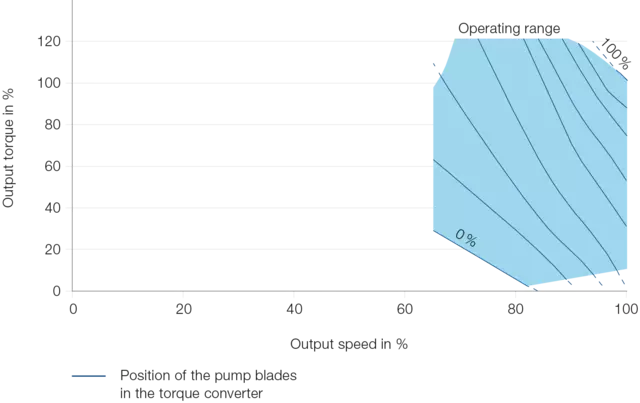

RWE-NX characteristic curves

Special benefits

- The Vorecon RWE-NX is a cost effective and simple solution for high speed turbo compressors.

- The horizontal split housing allows service to be carried out quickly and effectively, which is an important aspect for offshore systems.

- The consequently modular design allows interchangeability among different units.

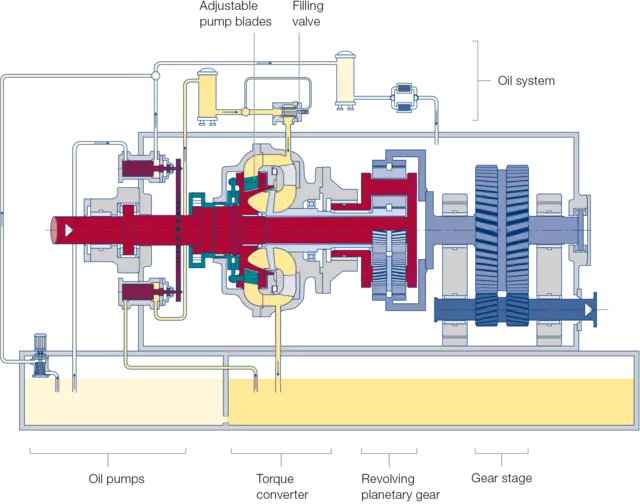

RWC-NX

Type RWC-NX – Modular and no-load starting

RWC-NX sectional diagram

Function

- During the starting sequence the filling of the torqueconverter is delayed by means of a filling valve. The mainmotor gets to full speed with lowest load torque.

- At rated speed of the main motor the torque converteris filled. The torque converter branches off the requiredpower for accelleration of the driven machine.

- The power branched off is superimposed in the revolvinggear.

- After reaching minimum speed the speed control is appliedusing the adjustable pump blades in the torque converter.

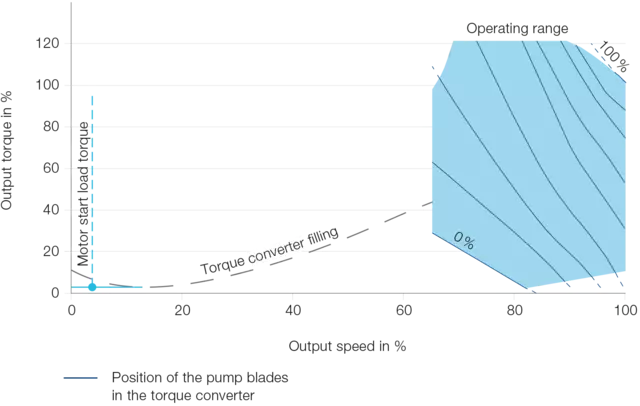

RWC-NX characteristic curves

Special benefits

- The drive motor starts unloaded. Therefore the driven machine can be started at weak grid conditions even if high inertia and high suction pressure are existent.

- The horizontal split housing allows service to be carried out quickly and effectively, which is an important aspect for offshore systems.

- The consequently modular design allows interchangeability among different units.

References

A Vorecon, now located in a USA pipeline compressor station.

Natural gas is the primary source of energy for Florida. The Vorecon is installed here and was delivered as a package.

Motor and Vorecon mounted together on a base frame with integrated oil supply system. Our customer originally intended to use VFDs but at the last moment, discovered the Vorecon. The customers initial thought was that the Vorecon would be too expensive and maintenance-intensive. We were delighted to disprove that thought and now have another satisfied Vorecon customer!

A Vorecon for a floating production, storage, and offloading system in Brazil.

Efficient drive systems for offshore production. Vorecon ensures reliable compressor control on FSO, FPSO & FLNG vessels.

FSO, FPSO, FLNG, and FSRU refer to vessels that store, process, and transfer oil or gas offshore. These environments are explosive, corrosive, space-limited, and subject to constant motion. High reliability is critical, as downtime is extremely costly. That’s why only systems with proven availability are used. Petrobras has relied on Vorecon units for over ten years on FPSOs for CO₂ injection and gas compressor trains. Today, more than 100 units above 8 MW are in successful operation worldwide.

Areas of application

The Vorecon is ideal for variable speed drive applications in power ranges from 1 to over 50 MW in the oil and gas industry, as well as in thermal power plants.