Pulping

The best-fit technology for each resource

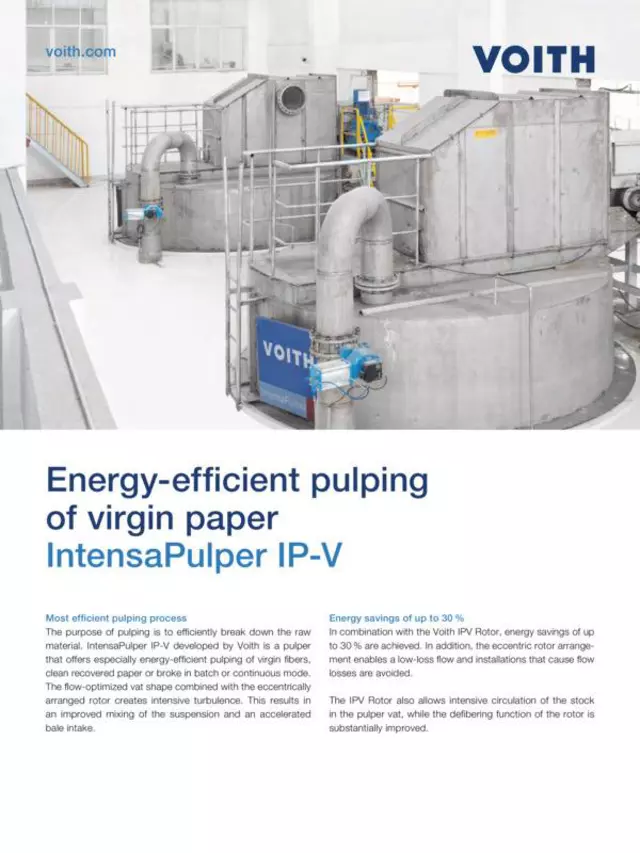

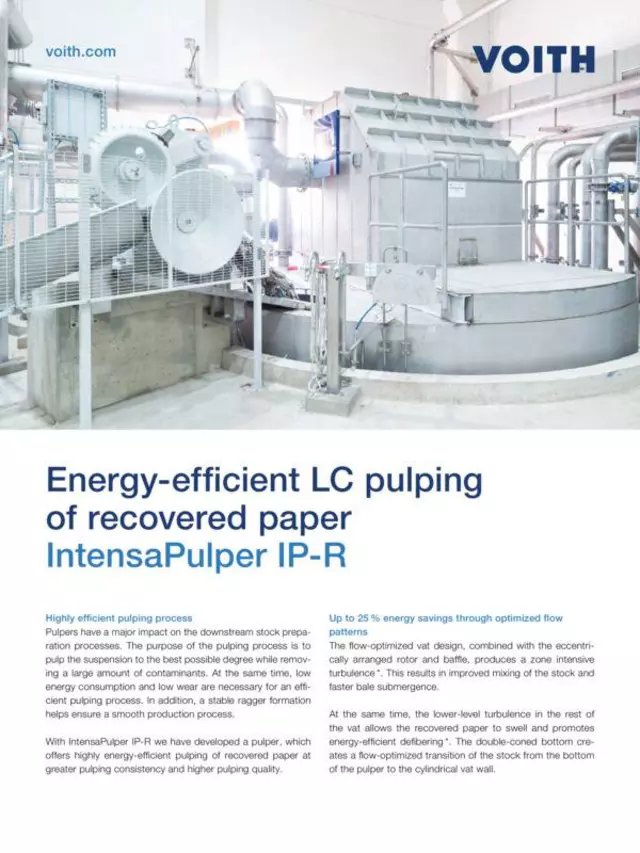

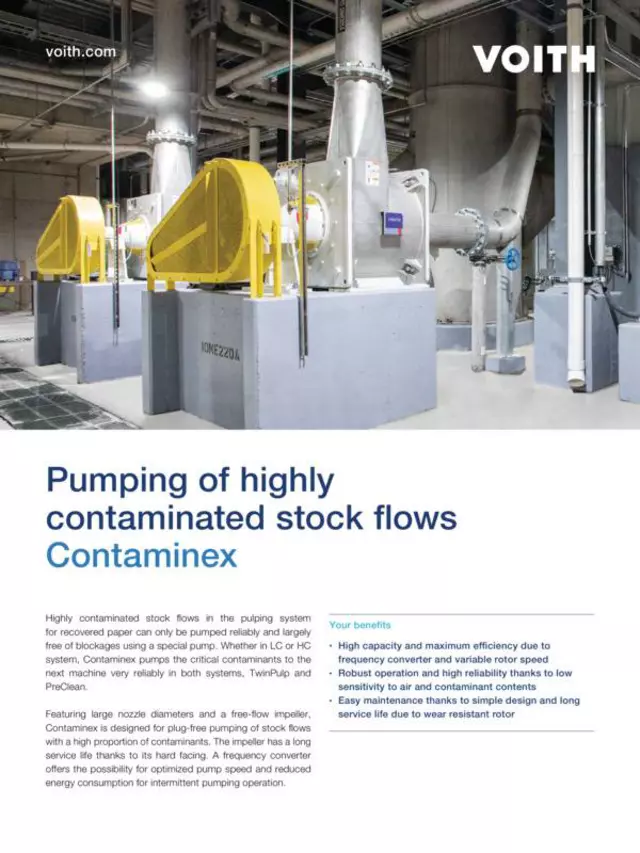

Pulping is the first step in the papermaking process, with the purpose of producing a clean fiber suspension that can be pumped forward in the process. Fibers from virgin pulp, recovered paper or paper machine broke are mixed, i.e., pulped, with water to form a suspension inside the pulper. The optimal pulping technology is selected depending on the type of furnish, production output and the contaminants in the furnish. Pulping systems for recovered paper not only disintegrate the paper and board into single fibers but also remove large non-fiber components (rejects), such as plastics or glass.

In order to avoid breaking the rejects into too small pieces, it is important for the pulping process to find a balance between the main parameters, such as pulping consistency, temperature, retention time and chemical additives. A low amount of rejects in the pulp makes the downstream process easier and more efficient to operate.

The right machine for every task

| Benefits | Process | |

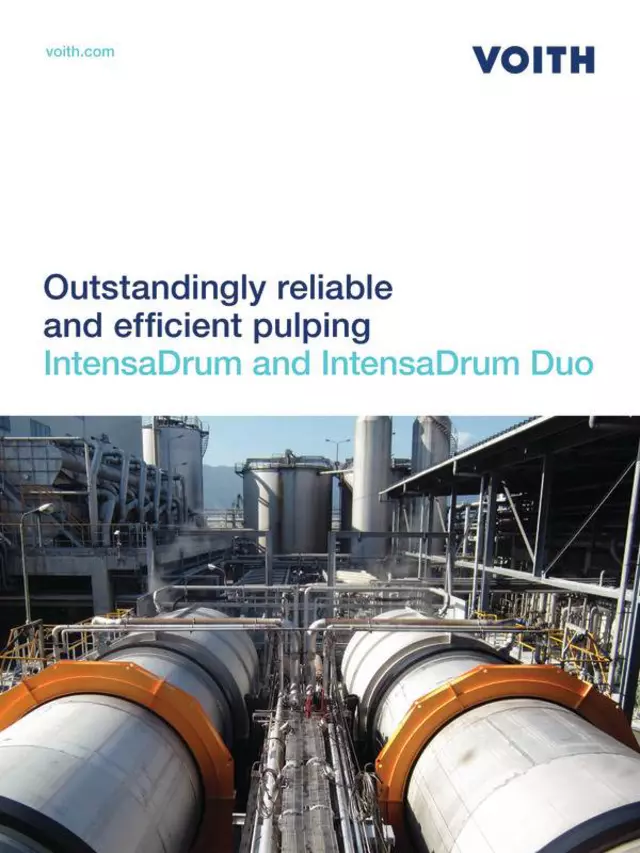

| IntensaDrum Duo |

High production High reliability |

Drum pulping for recycled fibers |

| IntensaDrum |

Enhanced safety Easy operation |

Drum pulping for recycled fibers |

| BluePulp LC |

Low energy demand Low fiber loss |

LC-Pulping System for recycled paper |

| IntensaPulper |

Flexibility Low energy demand |

Pulping of all kinds of paper and fiber material |

| IntensaPump |

High reliablity High throughput |

Pulper cleaning |

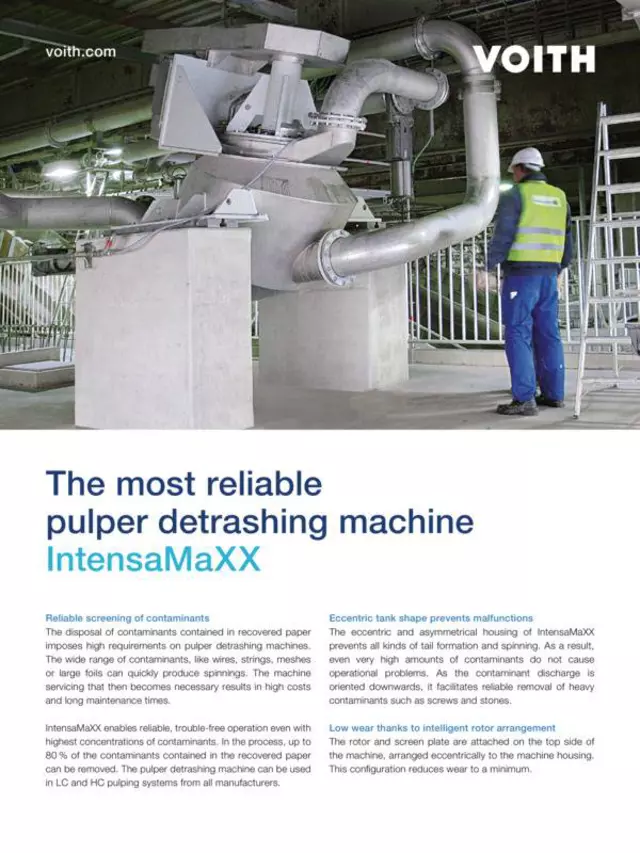

| IntensaMaXX |

High efficiency High reliability |

Pulper cleaning |

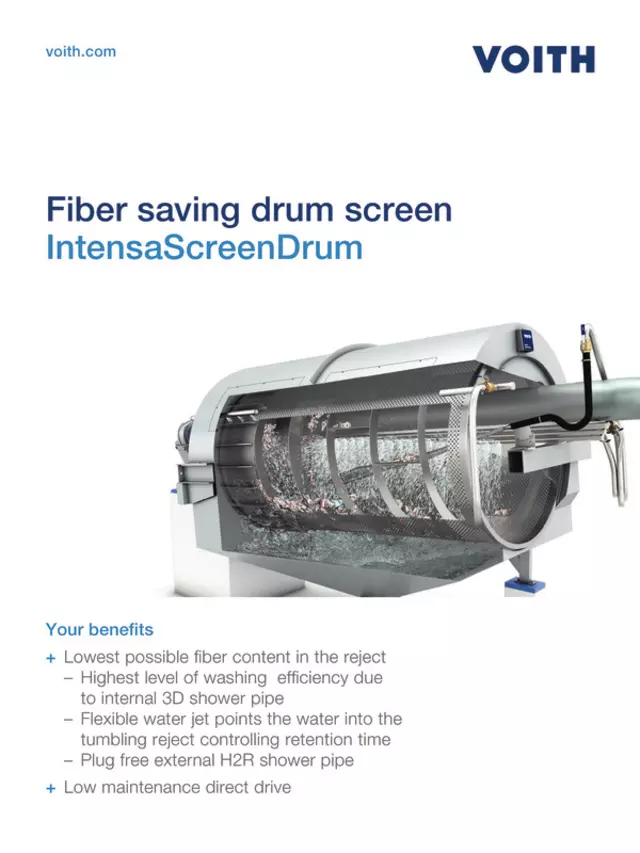

| IntensaScreenDrum |

Low fiber loss |

Reject washing |

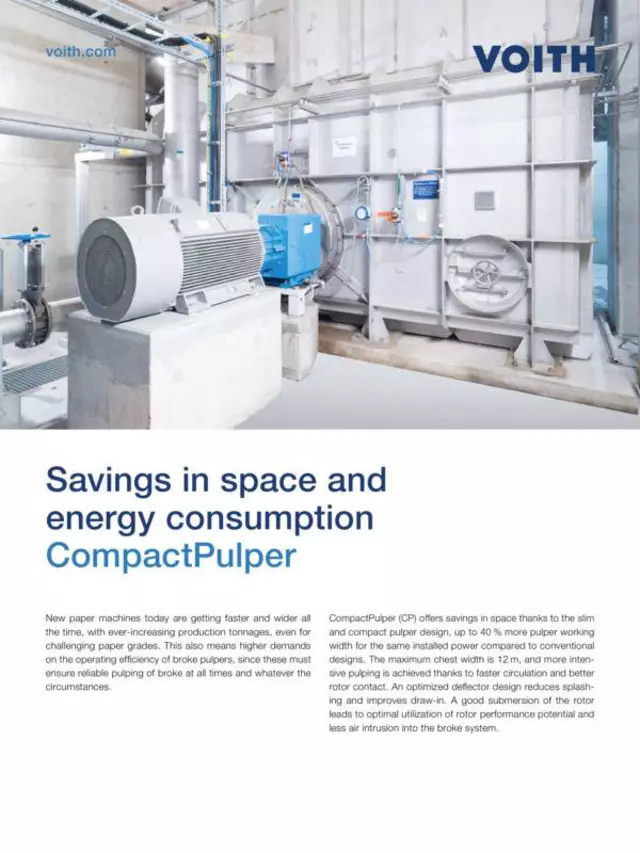

| CompactPulper |

Low energy demand Small footprint |

Broke pulping for paper machine |

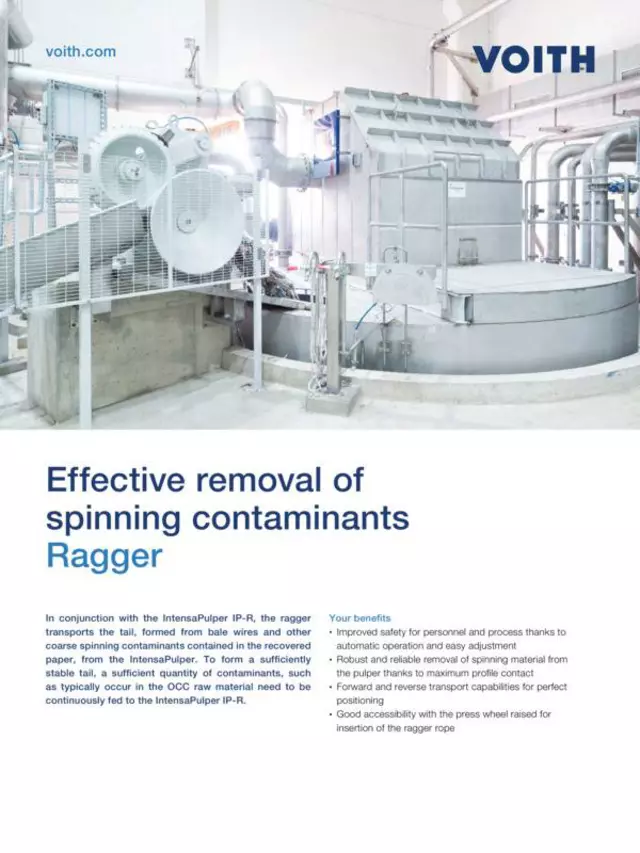

| Ragger |

High reliability |

Pulper cleaning |