Refining and deflaking

Improved stock quality through effective fiber treatment

Fiber treatment includes the most important actuating elements in terms of disintegration and surface treatment of each single fiber. Deflaking breaks up fiber bundles to prevent sheet brakes, thereby directly improving the paper machine runability. Refining increases the specific fiber surface of each single fiber resulting in higher strength potential due to fiber-fiber bonding and higher chemical absorption capacity.

Voith is the market leader for compact disk applications in the field of fiber treatment. Disk applications provide very good accessibility, enabling a fast and secure filling change with low downtimes.

New product: InfibraFiner

Voith’s InfibraFiner guarantees especially sustainable refining, by saving energy and raising throughput, while at the same time offering improved mechanical properties. In the DG (Digital Generation) version, cutting-edge sensors and the built-in SmartLight allow optimized refiner management and control.

The right machine for every task

| Feature | Process | |

| InfibraFiner | Energy-efficient refiner with increased capacity | Refining |

| TwinFlo |

Double-disk refiner for effective fiber handling |

Refining |

| Deflaker |

Energy-efficient disintegration of fiber bundles |

Deflaking |

Product range

InfibraFiner

Next generation refining

Voith’s latest refiner, the InfibraFiner, combines cutting-edge technology, ultra-modern industrial design, and digitalization. The development is based on more than 60 years of R&D and more than 1,000 successful installations of its predecessor, the TwinFlo Refiner.

The fiber treatment is especially sustainable, as the InfibraFiner demonstrably consumes less energy, offers higher hydraulic capacity, and extends the service life of the refiner fillings. The combination with the Voith Pluralis refiner fillings allows particularly gentle refining with reduced energy consumption. Compared with conventional refiners, the InfibraFiner achieves an additional production capacity of up to 28 percent. It also has an innovative design, with the gearbox integrated into the machine, for example.

Refining 4.0 with InfibraFiner DG

The optional “Digital Generation (DG) Package” offers even more bottom-line benefits. With the help of the SmartLight built into the cover of the refiner, operating personnel have information at all times and at a glance on the machine status, performance and current maintenance status, meaning that process deviations never go unnoticed again. Up to 15 latest-generation I/O-Link sensors generation are used for machine and process monitoring and optimize refiner control.

Especially valuable for operators are the unique contact detection, which identifies and pro-actively counteracts filling collisions, and the no-load power control, which allows enormous energy savings to be made. In addition, the wear condition of the fillings is constantly measured, so that the next filling change can be scheduled for the ideal time. All relevant information is displayed directly on the control panel next to the machine and in the control room, so that operating personnel can intervene at any time.

Outstanding design for optimum maintenance, safety and efficiency

The new design combines a modern look with numerous technological benefits that enable a much more consistent and energy-efficient refining process. For its outstanding industrial design, the InfibraFiner was awarded the Focus Open International Design Award Baden-Württemberg in silver by design experts. The user-friendly and safe maintenance of heavy parts also improves occupational safety and reduces the maintenance effort.

The BlueLine product range from Voith comprises modern machines and products for stock preparation that are characterized above all through the efficient use of energy and other raw materials and by gentle treatment of the fibers.

BlueLine Advantages

Higher Runability

Higher Runability

Thanks to cutting-edge sensors and the built-in SmartLight, optimized refiner management and control is possible. This results in fewer unscheduled downtimes and greater machine availability.

Lower Maintenance Cost

Lower Maintenance Cost

Thanks to the integrated gearbox, the bearing assembly and associated oil change are obsolete. Maximum filling service lives ensure longer maintenance cycles and monitoring by Maintenance Messenger ensures needs-based maintenance.

Lower Energy Consumption

Lower Energy Consumption

Thanks to the no-load control, up to 25% idle power can be saved during the service life of the filling.

Enhanced Safety

Enhanced Safety

A new rotor changing device (patent pending) ensures maximum occupational safety. Using this tool, the rotor can be secured, removed and put back into the machine without having to touch the rotor itself.

TwinFlo

Handling fiber in a uniform and highly efficient fashion

The TwinFlo double-disk refiner can effectively handle various fibers since it can be individually set by a multitude of available fillings. Targeted technological refining of primary and secondary fibers is the main task of the TwinFlo. It is characterized by electro-mechanical setting of the refining gap with central force transmission, the greatest possible flexibility with groove and knife geometry, and uniform filling wear due to hydraulic limiting factors in the disk refiner. Changing fillings is quick and easy.

The TwinFlo refiner is used in both fresh fiber lines as well as in secondary fiber lines. Due to the extensive assortment of fillings, suitable refining plates are available for nearly every application.

Your benefits with TwinFlo

- Optimal fiber treatment due to low-intensity refining

- Proven reliable technology

- Quick filling replacement due to easily accessibility

Deflaker

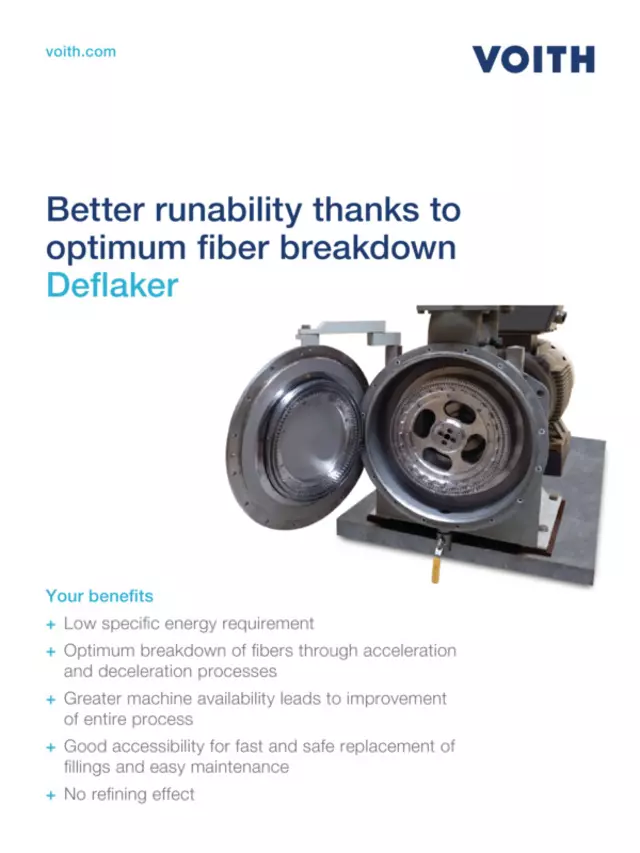

Energy-efficient disintegration of fiber bundles

The deflaker family brings about optimal separation of fiber bundles in virgin pulp and recovered paper pulp preparation through acceleration and delay processes. Process efficiency can thus be improved.

The proven filling design of the Voith deflakers allows the disintegration of wet-strength paper components and prepares machine broke. Thanks to its hinged cover, it is easily accessible and has no refining effect.

Four variants are available with nominal volume flows between 1,000 and 8,000 l/min and a reliable motor output of 90 to 800 kW. Thanks to the improved quality of the fiber suspension, the paper machine has fewer web breaks and therefore higher machine runability.

Your benefits with Voith deflakers

- Low specific energy requirement

- Intensive acceleration and deceleration of the stock for optimum deflaking

- Less breaks on the paper machine

- Quick filling replacement

- No refining effect

- Improves the efficiency of your processes

Engineered for success

At Zellcheming 2023, the audience got an exclusive insight into the experience of our pilot customer Klabin with the new InfibraFiner DG. Get free access to the video recording here.

Click here to view the full video

The IF90 DG is a great fit for us, and we are proud to have started up one of the very first machines at the Otacílio Costa mill. It has a robust design and is state of the art in terms of remote connection and onboard sensors and control systems.